Large-diameter vertical-shaft flying fin type explosion-proof door

A large-diameter, explosion-proof door technology, applied in door/window accessories, mining equipment, mining equipment, etc., can solve the problems of anti-wind failure, explosion-proof door flying, explosion-proof door damage, etc., to achieve easy opening and closing, locking Easy to operate and reduce impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

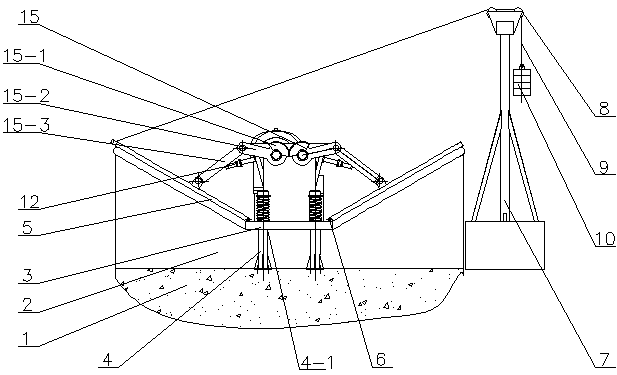

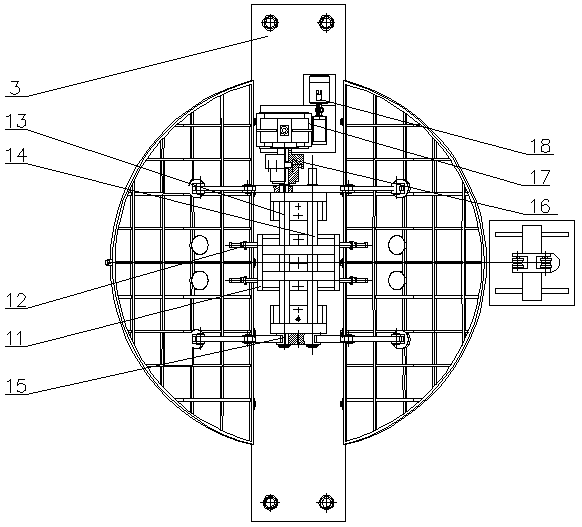

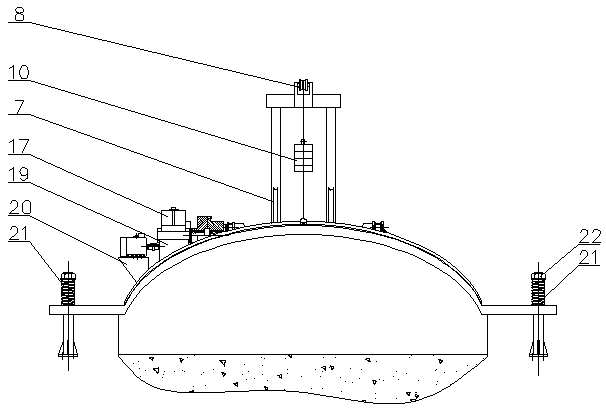

[0021] Such as figure 1 As shown in -3, the large-diameter vertical shaft fin type explosion-proof door includes an outer frame 2 set on the wellhead foundation 1. The horizontal surface of the outer frame 2 is circular, and the longitudinal section of the outer frame 2 is low in the middle and on the left and right sides. It is high, and there are hypotenuses between the middle part of the outer frame 2 and the left and right sides. A crossbeam 3 is set above the middle of the outer frame 2. The front and back ends of the crossbeam 3 extend out of the outer frame 2 and are supported on the wellhead foundation 1 by uprights 4. There are four uprights 4, of which two uprights 4 are located at the front end of the crossbeam 3. Two uprights 4 are located at the rear end of the beam 3. A shoulder 4-1 is provided on the column 4, the beam 3 rests on the shoulder 4-1 of the column 4, a spring 21 is sleeved on the column 4 above the beam 3, and a threaded connection with the column 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com