Stepless transmission

A technology of continuously variable transmission and variable speed ring, which is applied in the direction of gear transmission, friction transmission, transmission control, etc. It can solve the problems of small contact area at the power transmission, maximum torque and speed change stability limitations, etc., and achieve low cost, Low running wear and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

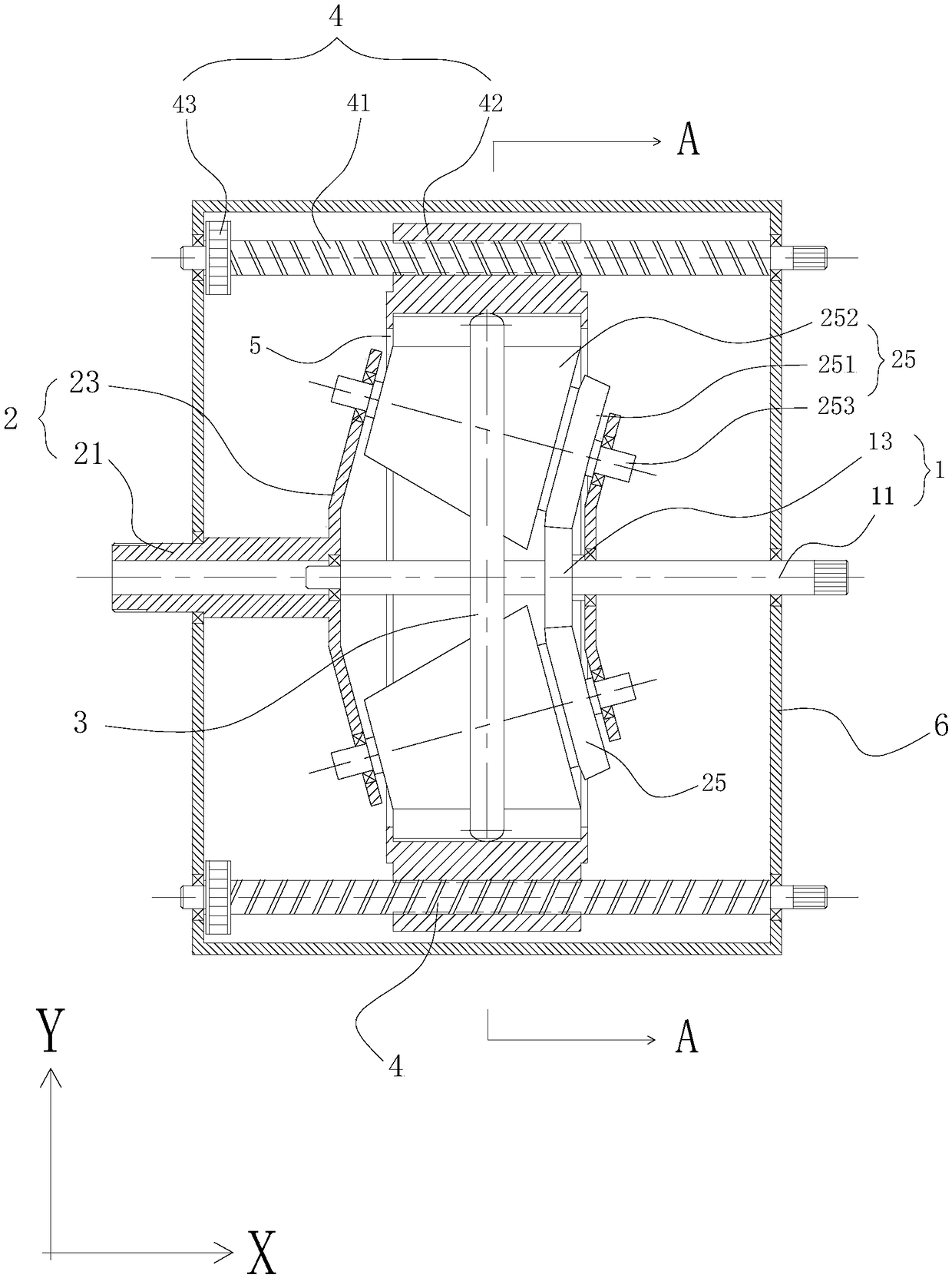

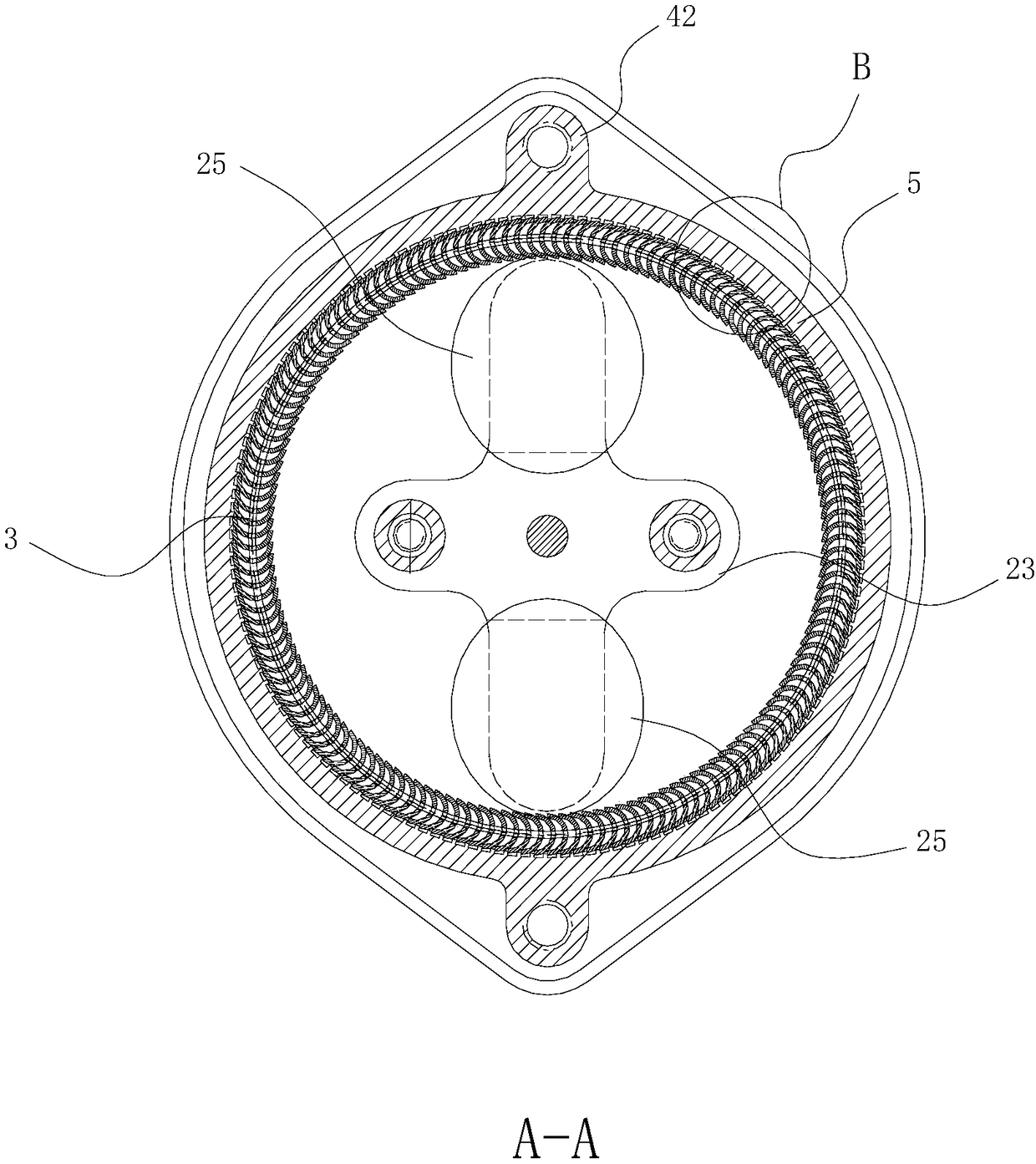

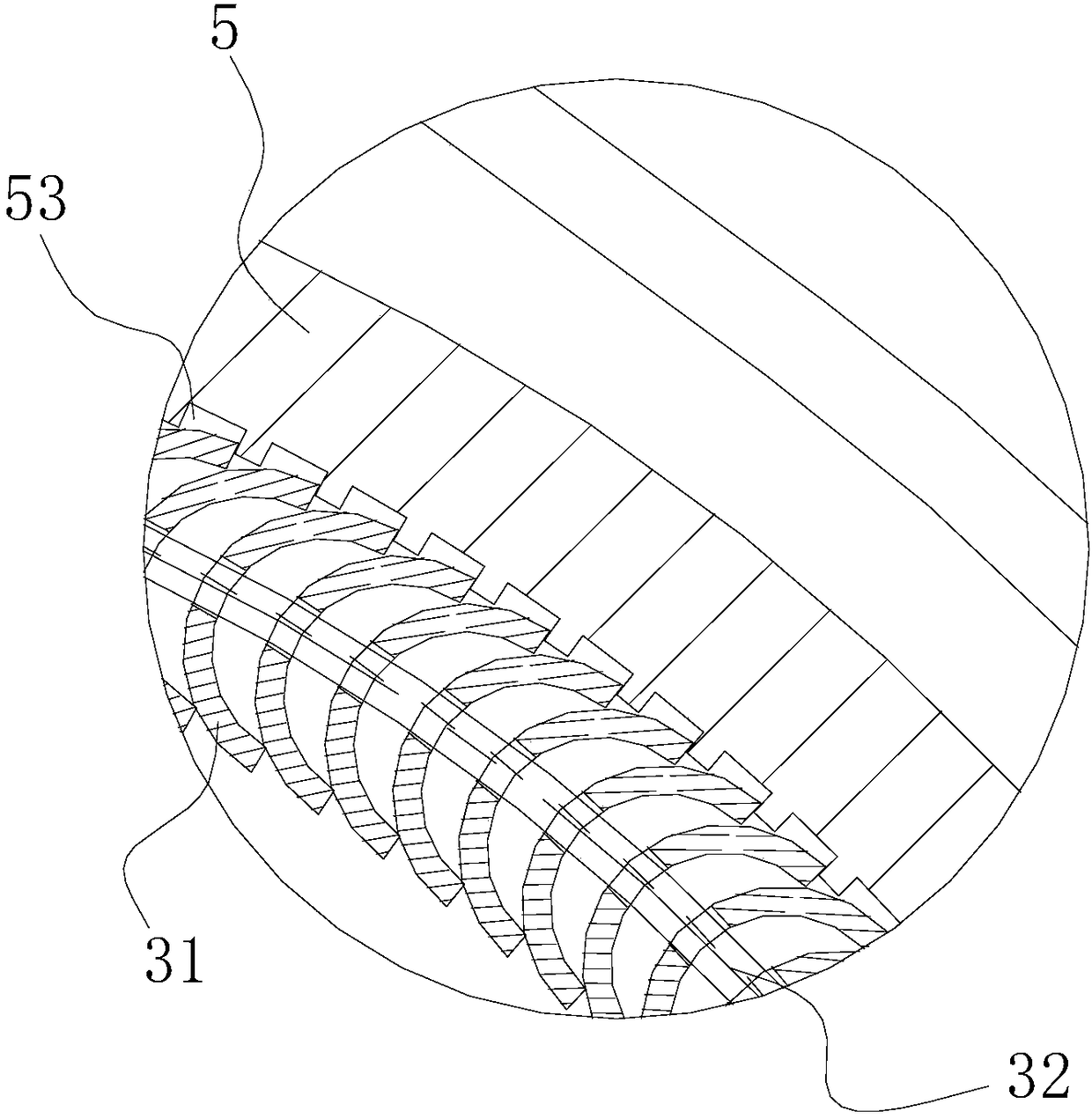

[0045] There are at least the following two problems in the existing mechanical continuously variable automatic transmission (CVT), which limit the maximum transmission torque of the transmission:

[0046] 1. The working contact surface is limited. If the positive pressure used to generate friction is too large, it will easily cause excessive stress on the mechanism and cause failure;

[0047] 2. The frictional force for power transmission and the frictional resistance to be overcome for speed change are on the same contact surface, and both are sliding friction. If the frictional force for power transmission is increased blindly, the speed change cannot be carried out smoothly.

[0048] Therefore, if the existing mechanical continuously variable automatic transmission is applied to vehicles or equipment with high torque and high motion performance requirements, at least the following problems will exist:

[0049] 1) The transmission belt is easy to be damaged, so the requirem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com