Square capacitor and manufacturing method thereof

A manufacturing method and capacitor technology, applied in the field of capacitors, can solve problems such as electrolyte volatilization, and achieve the effects of good sealing effect and strong manufacturing process operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

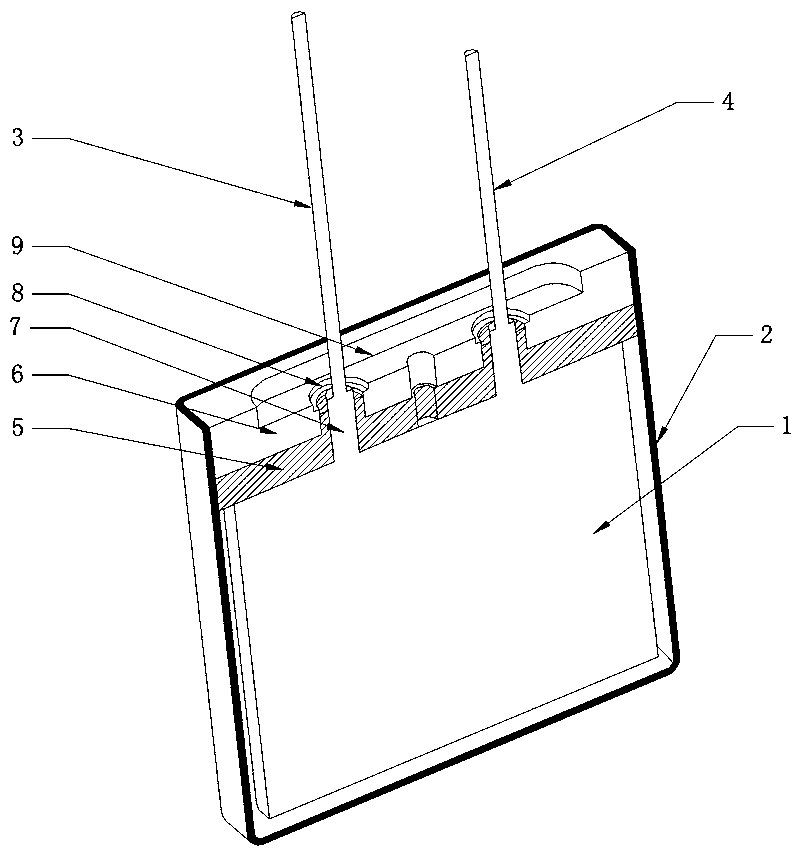

[0023] Such as figure 1 A square capacitor shown includes a core package 1, a casing 2 and a sealing assembly. The core package 1 is wound from positive electrode foil, negative electrode foil and electrolytic paper and is oval in shape. The positive electrode foil and the negative electrode foil are respectively connected with The positive guide pin 3 and the negative guide pin 4; the sealing assembly seals the core pack 1 in the shell 2, and the positive guide pin 3 and the negative guide pin 4 protrude from the shell 2; the sealing assembly includes a rubber plug 5 and a sealing cover 6, rubber The plug block 5 is provided with a through hole for the positive guide pin 3 and the negative guide pin 4, and the aluminum stem 7 of the positive guide pin 3 and the negative guide pin 4 is squeezed in the through hole by the rubber plug 5; The piercing holes of the positive guide pin 3 and the negative guide pin 4 are provided, and the first sealing step 8 is arranged on the pierc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com