A double-sided variable channel strong-plastic variable extrusion method and forming die for a rib-like member

A technology of extrusion forming and extrusion method, which is applied to metal extrusion dies, metal extrusion mandrels, etc., can solve the problems of small deformation, difficulty in obtaining ultra-fine grain structure, etc., and achieve the effect of ensuring the performance of fine grain structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

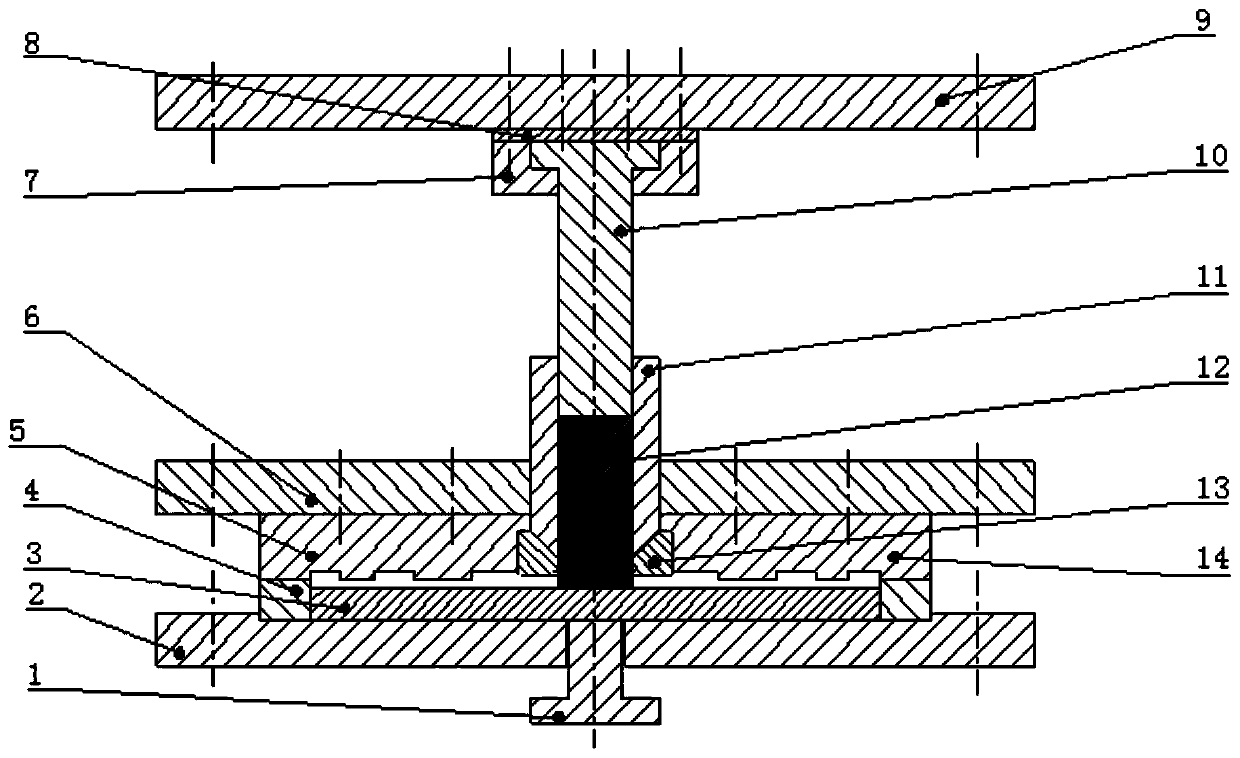

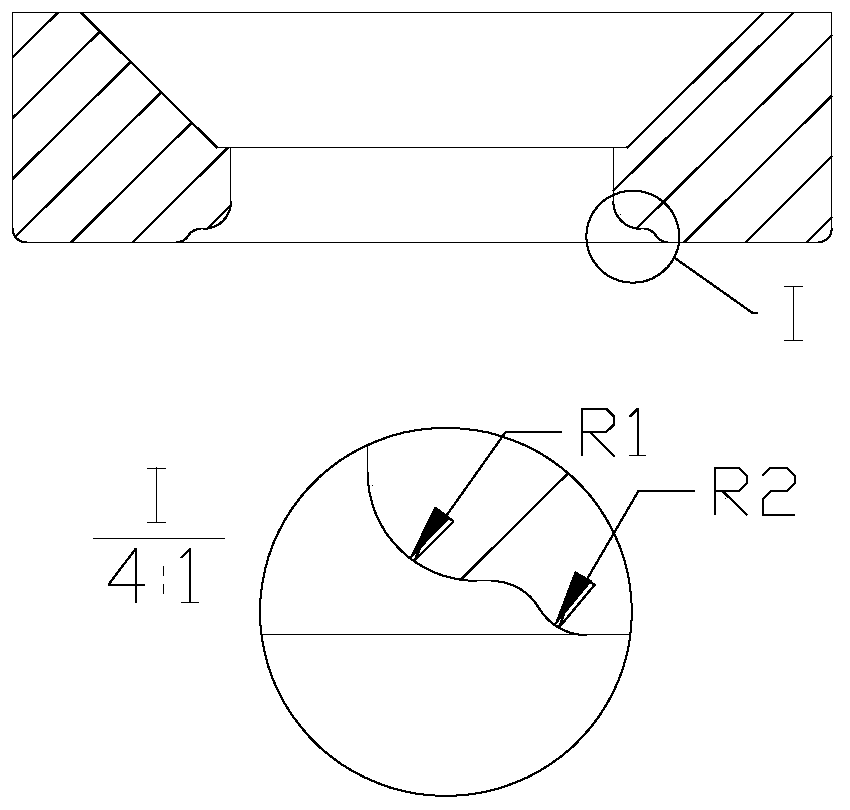

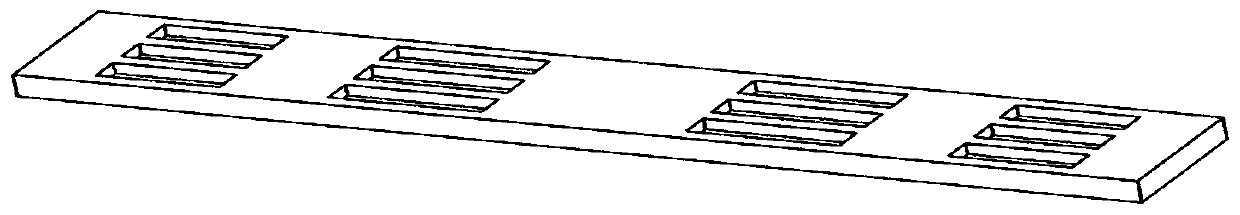

[0020] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, a double-sided variable channel strong plastic variable extrusion forming method of a magnesium alloy thin-walled rib member is described in detail with reference to the accompanying drawings. The embodiments include the forming of magnesium alloy thin-walled ribbed members, which are only part of the embodiments of the present invention, not all embodiments. The present invention is also generally applicable to aluminum alloy and titanium alloy ribbed members.

[0021] Such as figure 1 Shown, described a kind of magnesium alloy thin-wall rib member double-sided variable channel strong plastic variable extrusion molding die, its use steps are:

[0022] The first step: fix the upper mold seat cover 7, the punch 10 and the backing plate 8 on the upper template 9 by bolts;

[0023] Step 2: Fix the lower template 2 and the upper template 9 to the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com