An automatic wall brushing device for working at heights

A technology for automatic wall painting and high-altitude operation, which is applied in the direction of construction and building structure, and can solve the problems of dangerous working environment, affecting the painting effect, and different painting effects of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

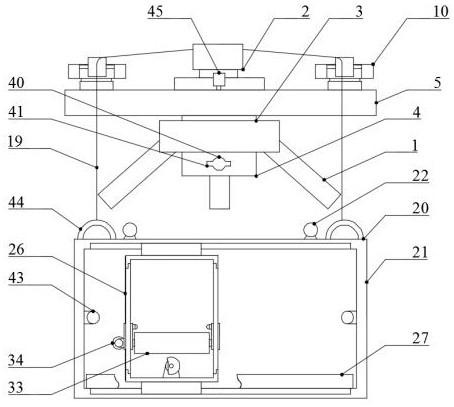

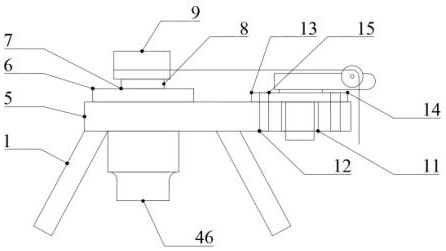

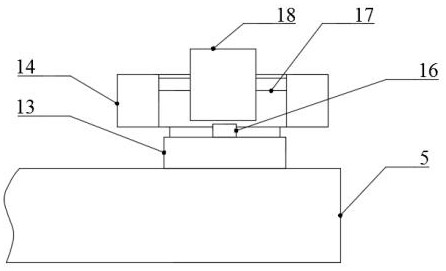

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 , an automatic wall brushing device for high-altitude operations, including a fixed bracket 1, a wire winding device 2 is arranged above the fixed bracket 1, and the wire winding device 2 is formed by a mounting hole opened in the middle of the upper surface of the fixed bracket 1 3. The fixed rod 4 set in the installation hole 3, the coil plate 5 fixedly connected to the upper surface of the fixed rod 4, the installation sleeve 6 located above the coil plate 5 and fixedly connected to the middle position of the front end of the upper surface of the coil plate 5, The rotating bearing 7 set in the installation sleeve 6, the bobbin 8 set in the swivel bearing 7, the winding motor 46 fixedly connected to the lower surface of the winding plate 5 and fixedly connected to the winding shaft 8 under the winding plate 5 and The winding wheel 9 set on the upper end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com