Straight handle type spraying gun

A straight-handle, spray gun technology, applied in the direction of spray devices, single handheld devices, etc., can solve the problems of inaccessibility and inconvenient operation, and achieve the effects of saving materials, increasing hand feeling, improving practicability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

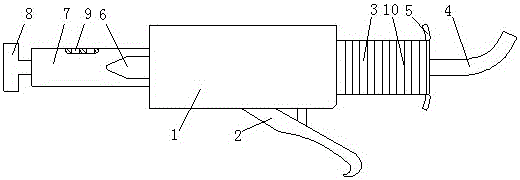

[0019] Such as figure 1 As shown, in this embodiment, a straight-handled spray gun includes a gun body 1, a trigger 2 connected to the gun body 1 and used to control the painting process, a handle 3 installed on the gun body 1, a handle 3 that runs through the handle 3 and is connected to the gun body 1. The air pipe 4 connected to the gun body 1 and the nozzle 6 installed on the gun body 1 for spraying paint, the handle 3 and the gun body 1 are arranged in a straight line.

[0020] By adopting the above method, the space limitation of the handle 3 on the whole device can be reduced, so that when spraying the paint on the surface of the inner hole, the present invention can be directly inserted into the inner hole to realize the painting operation of the inner hole, which is simple and convenient. Improve the flexibility and practicability of the present invention.

Embodiment 2

[0022] This embodiment is further improved on the basis of the above embodiments. In this embodiment, a straight-handle spray gun includes a gun body 1, a trigger 2 connected to the gun body 1 and used to control the painting process, and a trigger 2 installed on the gun body. The handle 3 on the 1, the air pipe 4 that runs through the handle 3 and is connected to the gun body 1, and the nozzle 6 installed on the gun body 1 for spraying paint, the handle 3 and the gun body 1 are arranged in a straight line, and the nozzle 6 outer cover is provided There is a cover 7 for specifying the spraying direction of the paint, and a paint outlet 9 is opened on the side wall of the cover 7 .

[0023] With the above structure, the paint outlet 9 is used to specify that the spraying direction of the paint material is perpendicular to the gun body 1 during painting, so that the present invention can directly carry out the painting operation after being inserted into the inner hole, and the s...

Embodiment 3

[0025] This embodiment is further improved on the basis of the above embodiments. In this embodiment, a straight-handle spray gun includes a gun body 1, a trigger 2 connected to the gun body 1 and used to control the painting process, and a trigger 2 installed on the gun body. The handle 3 on the 1, the air pipe 4 that runs through the handle 3 and is connected to the gun body 1, and the nozzle 6 installed on the gun body 1 for spraying paint, the handle 3 and the gun body 1 are arranged in a straight line, and the nozzle 6 outer cover is provided There is a cover 7 for specifying the spraying direction of the paint, the side wall of the cover 7 is provided with a paint outlet 9, and the top of the cover 7 is connected with a recovery mechanism 8 for recovering excess paint.

[0026] Since the paint sprayed from the nozzle 6 has generally been atomized, it is in the form of mist, so after it is sprayed from the nozzle 6, the situation of the paint spreading in all directions is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com