Automobile seat armrest

A technology for car seats and armrests, applied in the direction of armrests, etc., can solve the problems of insensitive adjustment and inability to locate, and achieve the effects of sensitive and reliable adjustment and positioning, convenient adjustment and positioning, and reliable installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

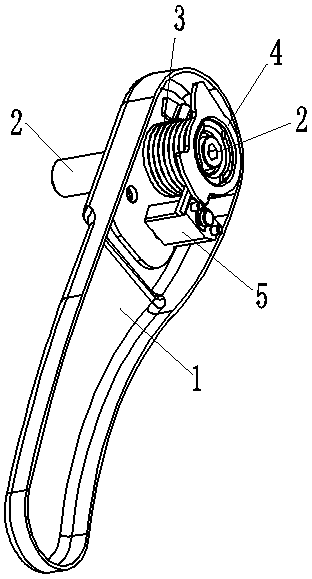

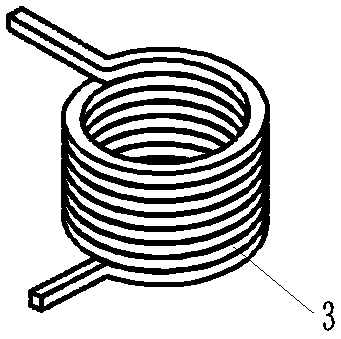

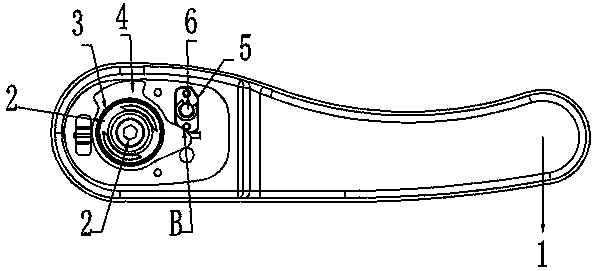

[0013] figure 1 , 2 , 3, and 4 show: the support plate 1 of the armrest of the car seat is equipped with a retaining spring 3 that can hold the axle rod 2 in place through the shaft rod 2 at the fixed end. One end is fixed on the support plate 1 by a fixed block, the other end is under the twist plate, and a positioning and rotating block 5 is provided on one side of the twist plate 4 . The inner diameter of the sleeved snap ring 3 is smaller than that of the shaft rod 2 . The positioning and rotating block 5 is movably fixed on the support plate 1 through a pivot pin.

[0014] The working principle of the present invention is as follows: when the outer end of the handrail is lifted, the A area of the torsion plate 4 moves the positioning and rotating block 5 to make it rotate around the pivot pin until the short straight side of the positioning and rotating block 5 sticks to the plane of the circlip, so that The circlip 3 is in the expanded state, and in this state the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com