Rotary vane steering gear and mounting method thereof

An installation method and steering gear technology, which are applied to the fluid pressure actuating device and other directions, can solve the problems of affecting the normal operation of the rotary vane steering gear, difficult installation of the rotary vane steering gear, and damage to the end face sealing ring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

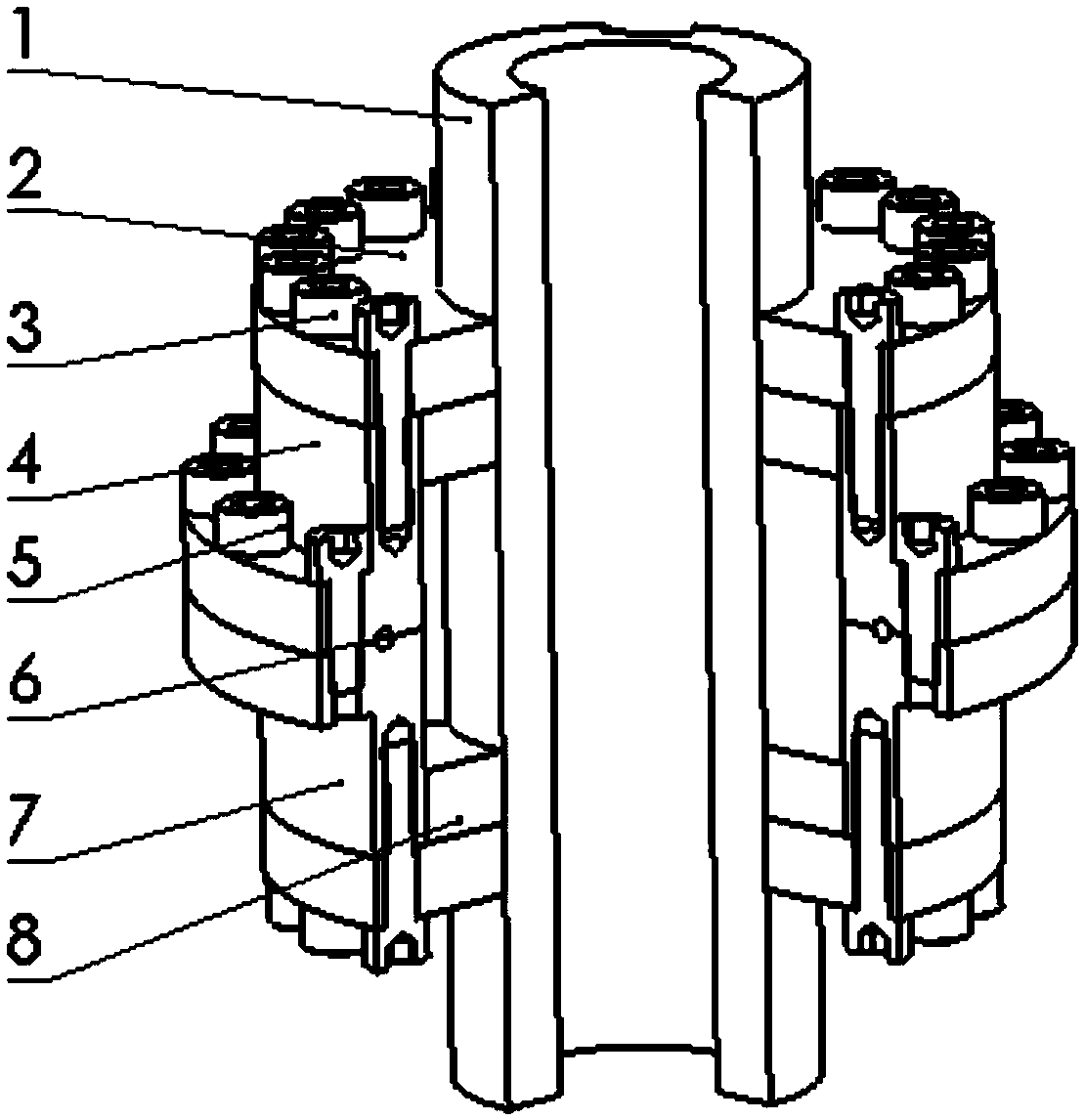

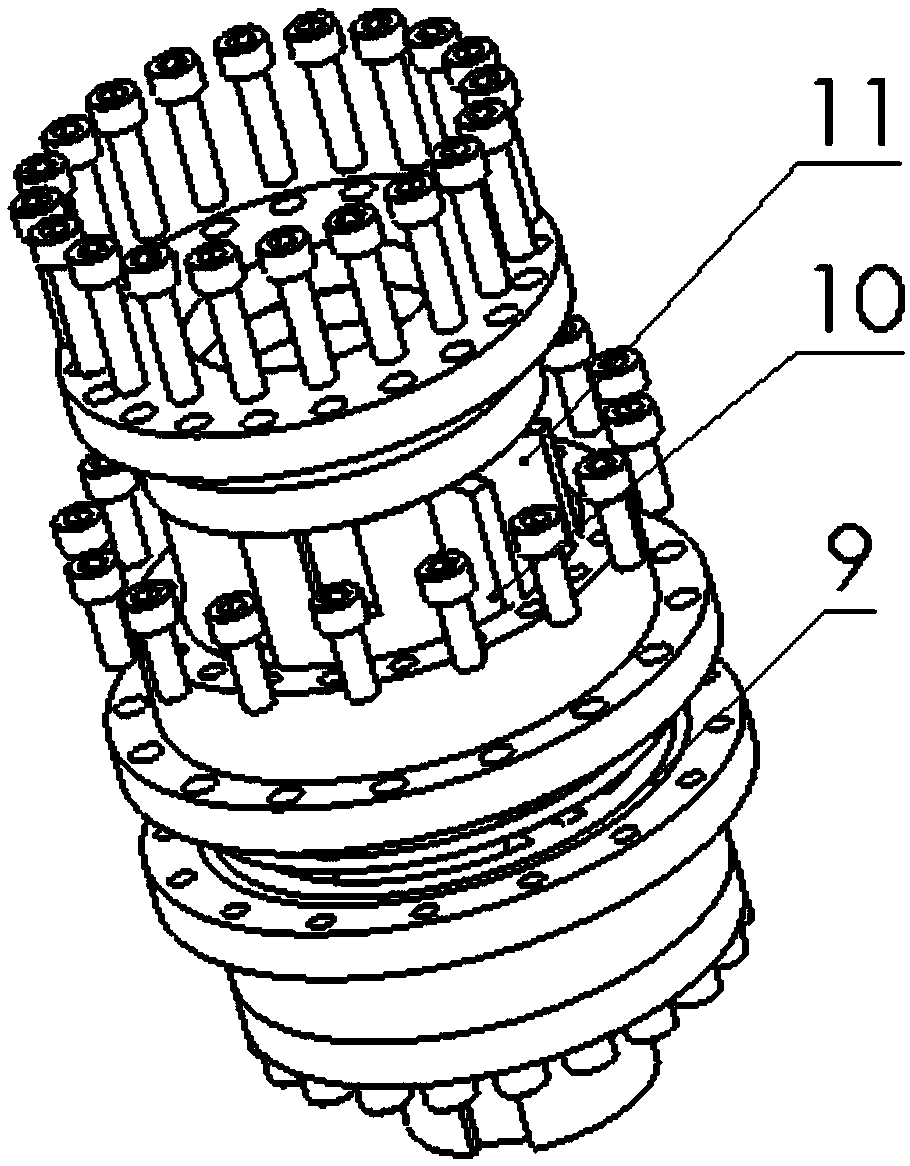

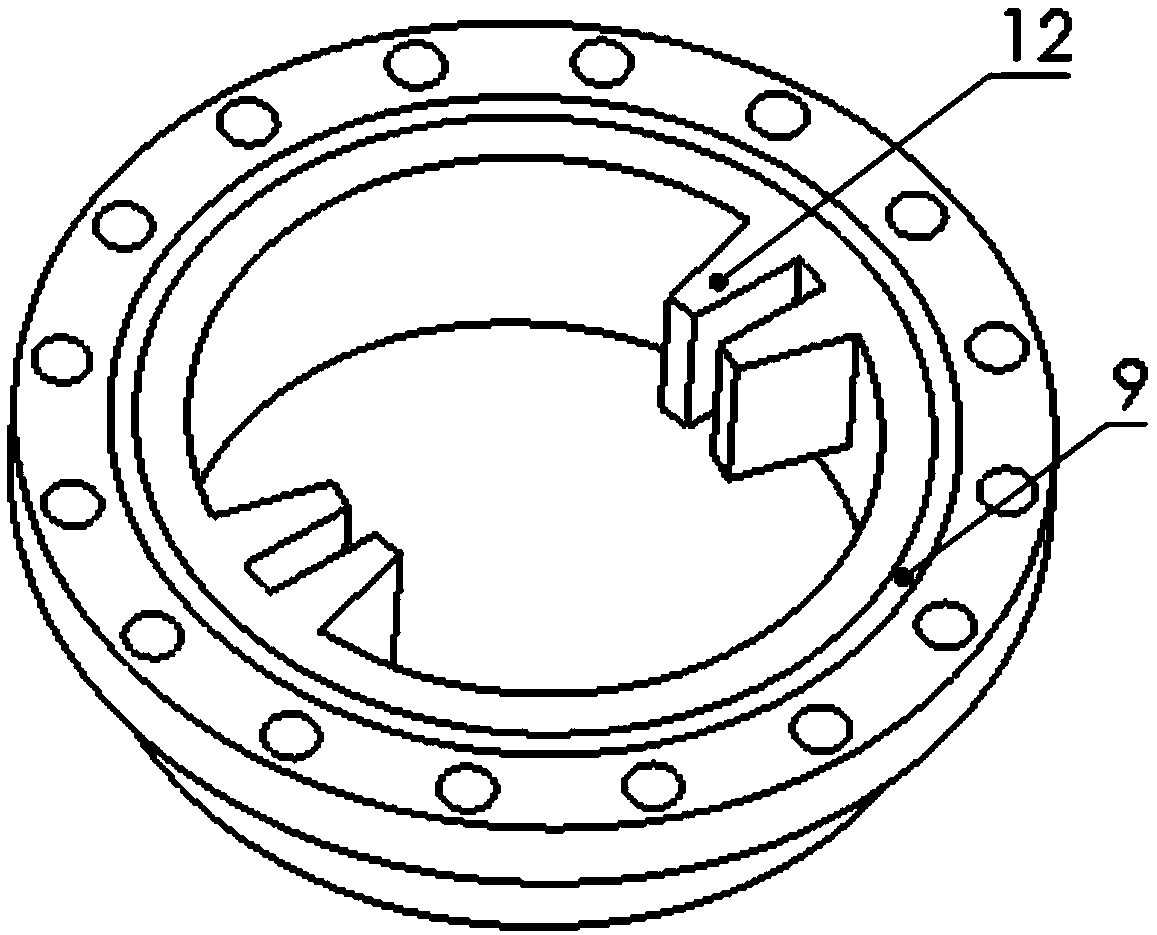

[0022] like Figures 1 to 5 As shown, a rotary vane steering gear includes a rotor 1, a cover plate 2, a cover plate screw 3, an upper cylinder body 4, cylinder body screws 5, an O-ring 6, a lower cylinder body 7, an end face sealing ring 8, an O-ring Ring groove 9, rotor blade 10, cylinder blade 11, lower cylinder blade support 12, rotor blade support 13, keyway 14 and upper cylinder blade support (not shown).

[0023] The upper cylinder 4 and the lower cylinder 7 have the same symmetrical structure, and the upper cylinder blade support and the lower cylinder blade support 12 are respectively arranged inside the two, and the upper cylinder 4 Combining up and down with the lower side cylinder 7 together constitutes the cylinder part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com