Structural body rotatable entry testing device

A structure and water test technology, which is applied in fluid dynamics test, machine/structural component test, measuring device, etc., can solve the problems of high cost, inability to realize the process of structure rotation into water, and inability to support system analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

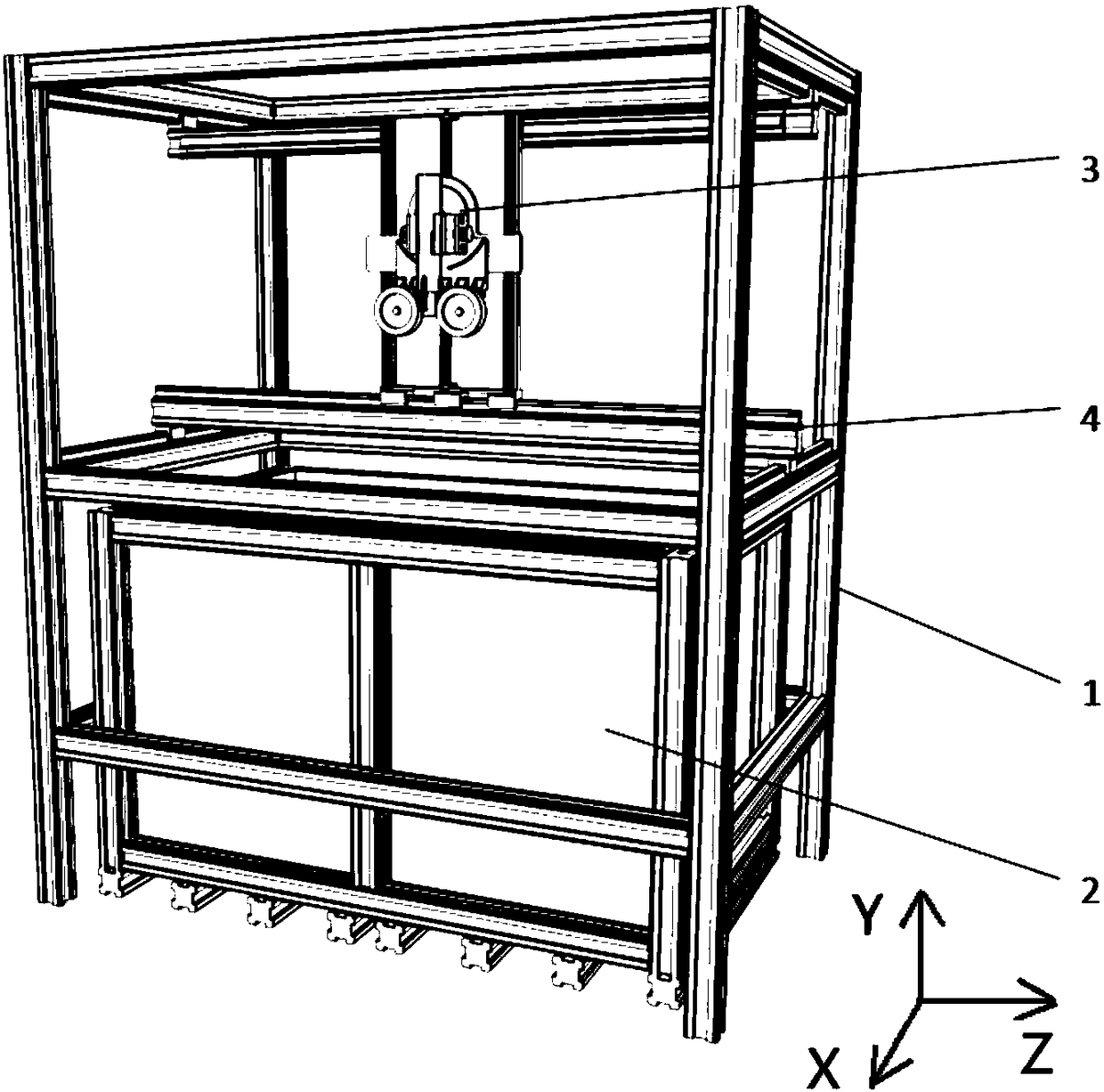

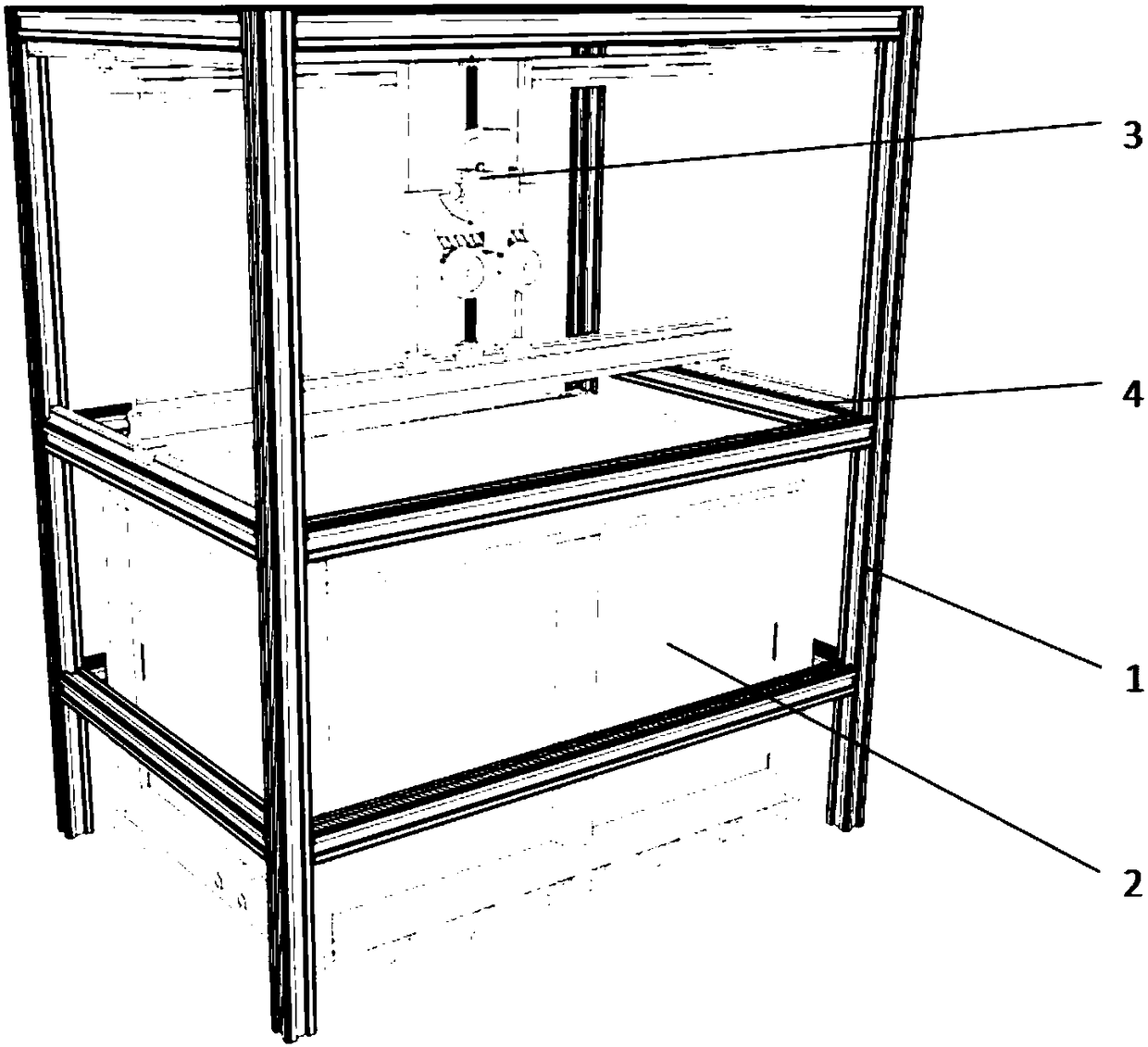

[0028] See attached figure 1 , a rotatable water entry test device for a structure, comprising: a support 1, a water storage tank 2 with an upper opening, a rotating launch assembly 3 and a position adjustment assembly 4;

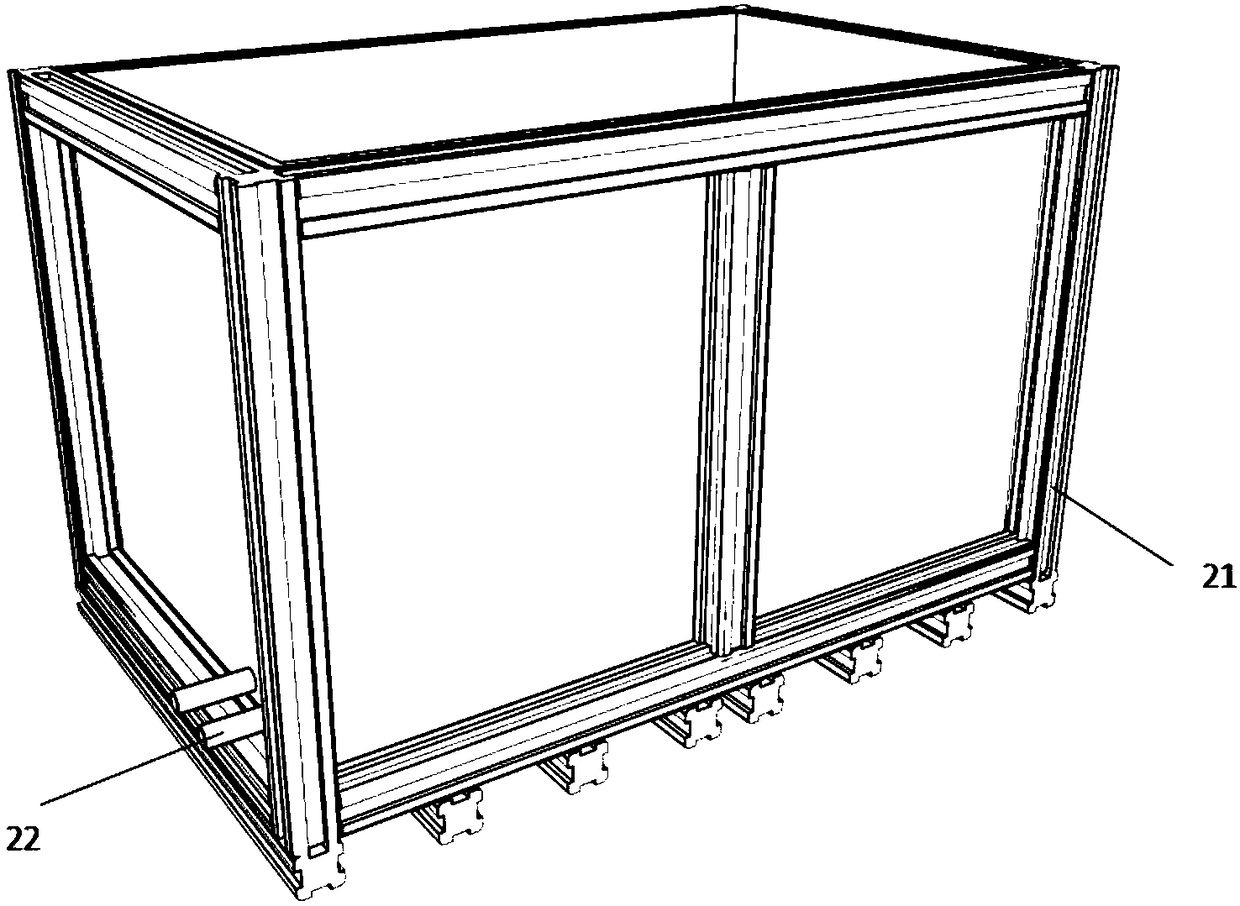

[0029] See attached figure 2 , the side and bottom surface of the water storage tank 2 are made of plexiglass; the outer contour and bottom of the water storage tank 2 are fixed with a profile bracket 21 to strengthen the structural stability of the water storage tank 2; the bottom of the water storage tank 2 is provided with a drain valve 22 for easy replacement water quality;

[0030] See attached image 3 , the support member 1 is covered on the water storage tank 2, and is used for loading the position adjustment assembly 4 and the rotating launching assembly 3;

[0031] See attached Figure 5 , the position adjustment assembly 4 includes: a primary adjustment track 41 that is slidably installed on the support member 1 for realizing forward and bac...

Embodiment 2

[0036] See attached Figure 7 , in this embodiment, the mechanical claw assembly 6 is replaced by a V-shaped block part, and the structure is clamped by the V-shaped block part installed between the two clamping steel plates 323; in order to enable the structure to rotate into the water, the A friction wheel 33 is arranged on both sides of the water entry route of the structure below the rotating part 31. The axes of the two friction wheels 33 are parallel, and the distance between the two friction wheels 33 is consistent with the diameter of the structure. The two friction wheels 33 are driven by their respective motors , when the structure passes through the two friction wheels 33, the two rotating friction wheels 33 drive the structure to rotate, so that the structure has a certain speed of entering the water (rotation around its own axis). And by changing the rotation speed of the friction wheel 33, the initial rotation speed of the structure body entering the water can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com