LED display screen seam correcting method

An LED display and display technology, applied in static indicators, instruments, etc., can solve the problems of LED module lamp bead position offset error, inaccurate correction brightness coefficient, LED lamp bead spacing error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

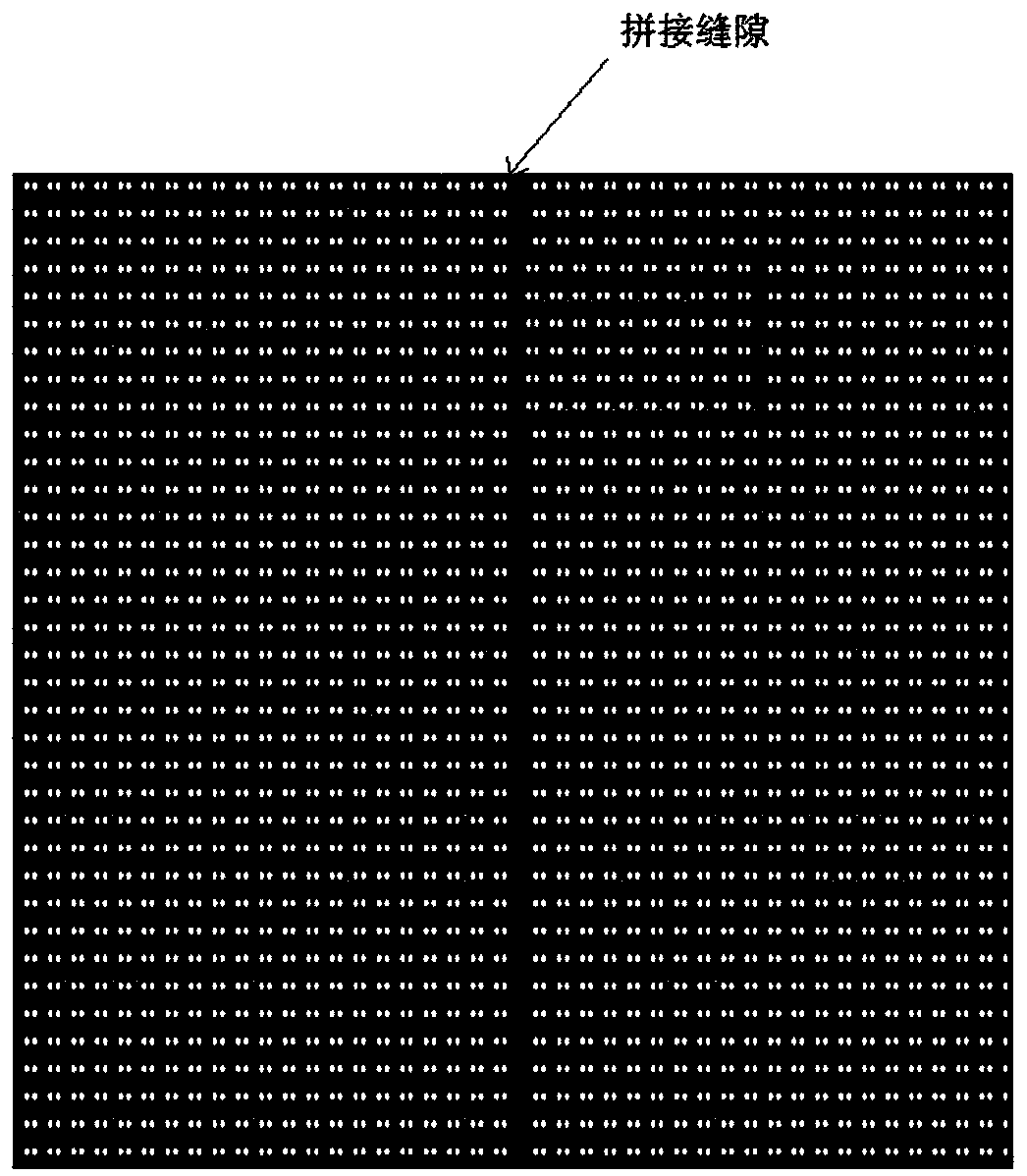

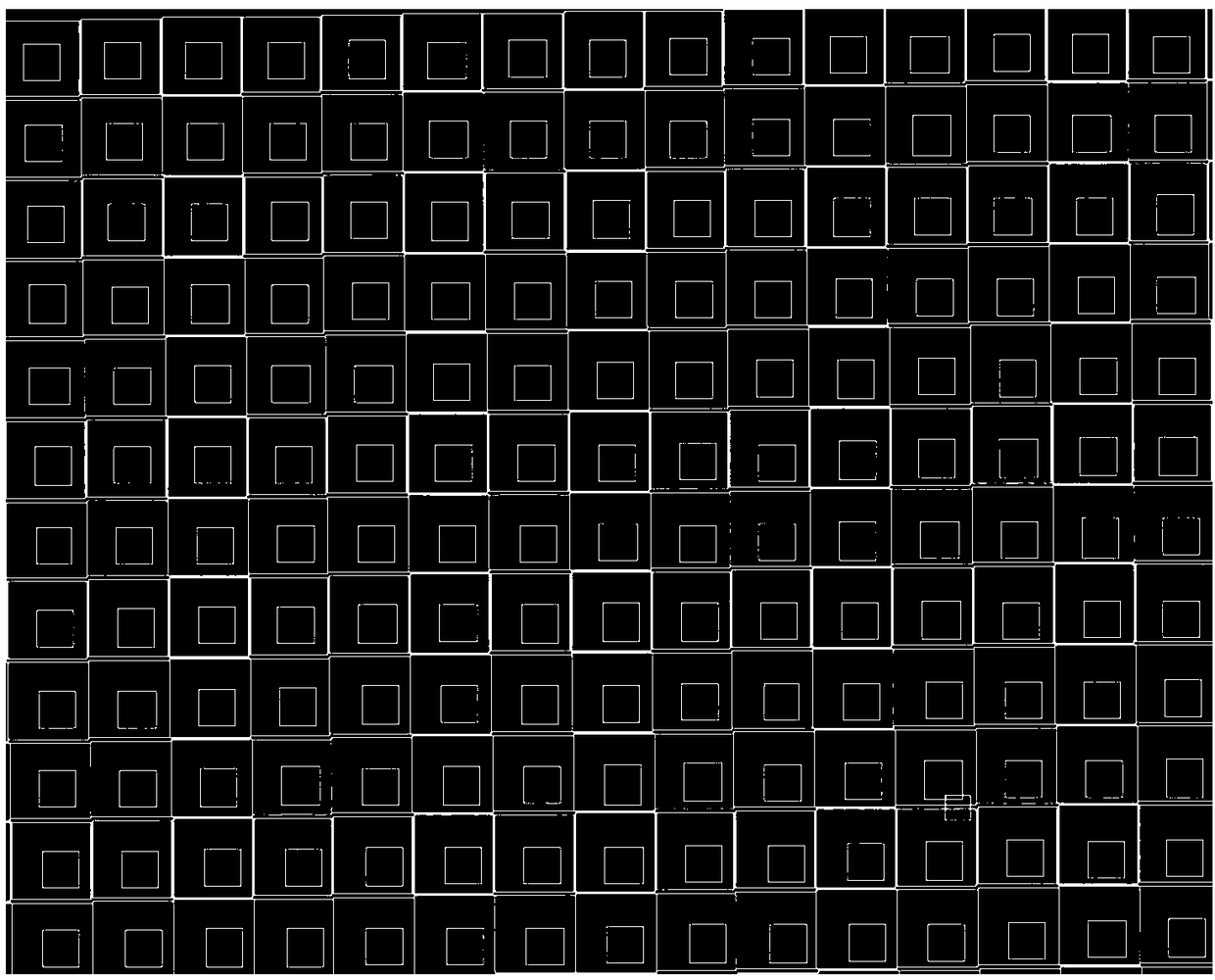

[0040] refer to Figure 1-Figure 5b As shown, the present invention provides a method for correcting LED display seams, comprising the following steps:

[0041] Step (1): Determine the size of the bright and dark line areas that the splicing units of the splicing display module are alternately arranged in the X and Y axis directions, wherein step (1) includes: Step (1.1): according to the splicing of the LED display module The position of the bright and dark lines formed by the full screen divides the entire spliced LED display module into different equal areas according to the principle of uniform distribution; step (1.2): determine the splicing display according to the size of the splicing unit that divides the adjacent display module areas in the spliced display The splicing units of the screen module are arranged alternately in the X and Y axis directions of the bright and dark line areas, where the X and Y axis directions are the directions of the splicing gaps betwee...

Embodiment 2

[0050] The steps of a splicing bright and dark line correction method: ① determine the selected splicing display splicing unit and adjacent splicing units in the X / Y axis direction according to the size of the selected splicing display splicing unit and adjacent splicing units The size of multiple divided area module units that are repeatedly arranged, each of which includes multiple display module units; A plurality of display units at the designated X / Y coordinate positions of each of the multiple division area modules for the selected mosaic display screen splicing unit and the adjacent splicing unit to obtain the shooting target image , where the specified X / Y coordinate position of the selected splicing display splicing unit is a display bright block composed of a plurality of display module units; ④ Calculate the brightness correction coefficient of each edge display unit of the splicing gap between the specified selected splicing display screen splicing unit and adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com