Splicing bright-dark line correction method

A bright and dark line, splicing technology, applied in the direction of instruments, static indicators, etc., can solve the problems of inaccurate correction coefficient, uneven screen body, LED light point spacing error, etc., to reduce calculation errors and avoid calculation inaccuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

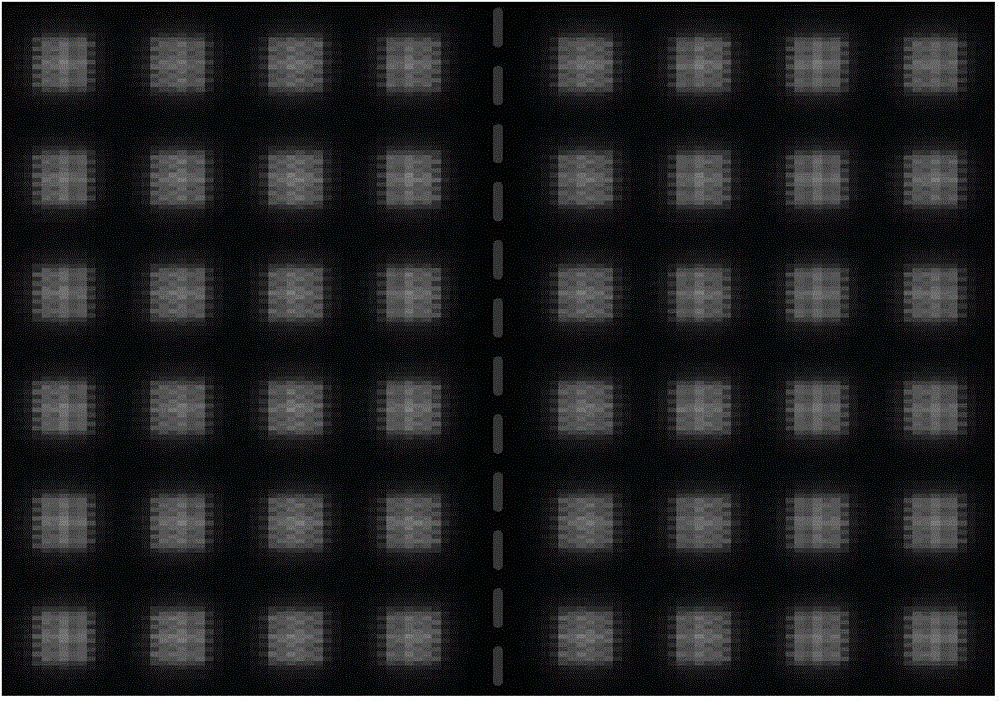

[0033] See Figure 2 to Figure 6 The splicing bright and dark line correction method suitable for a spliced display such as an LED display provided by the first embodiment of the present invention can be realized by the following technical solution. specifically:

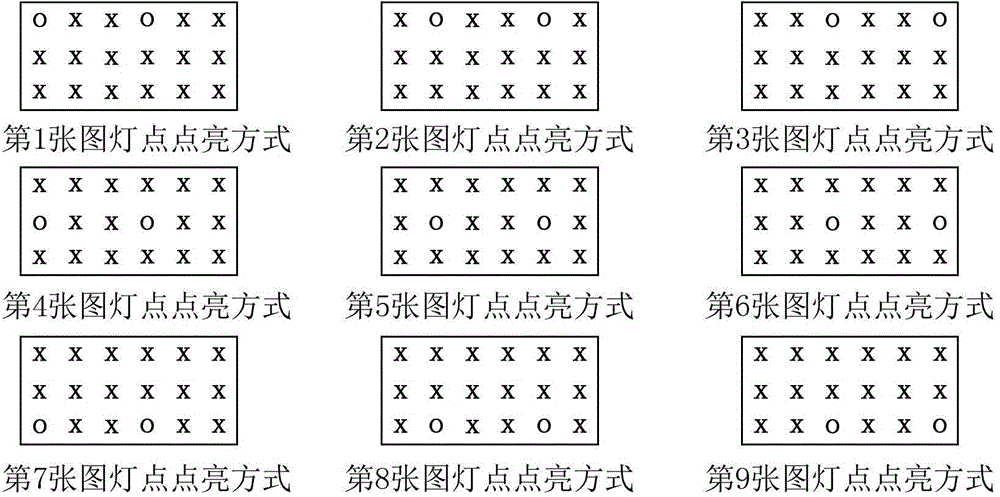

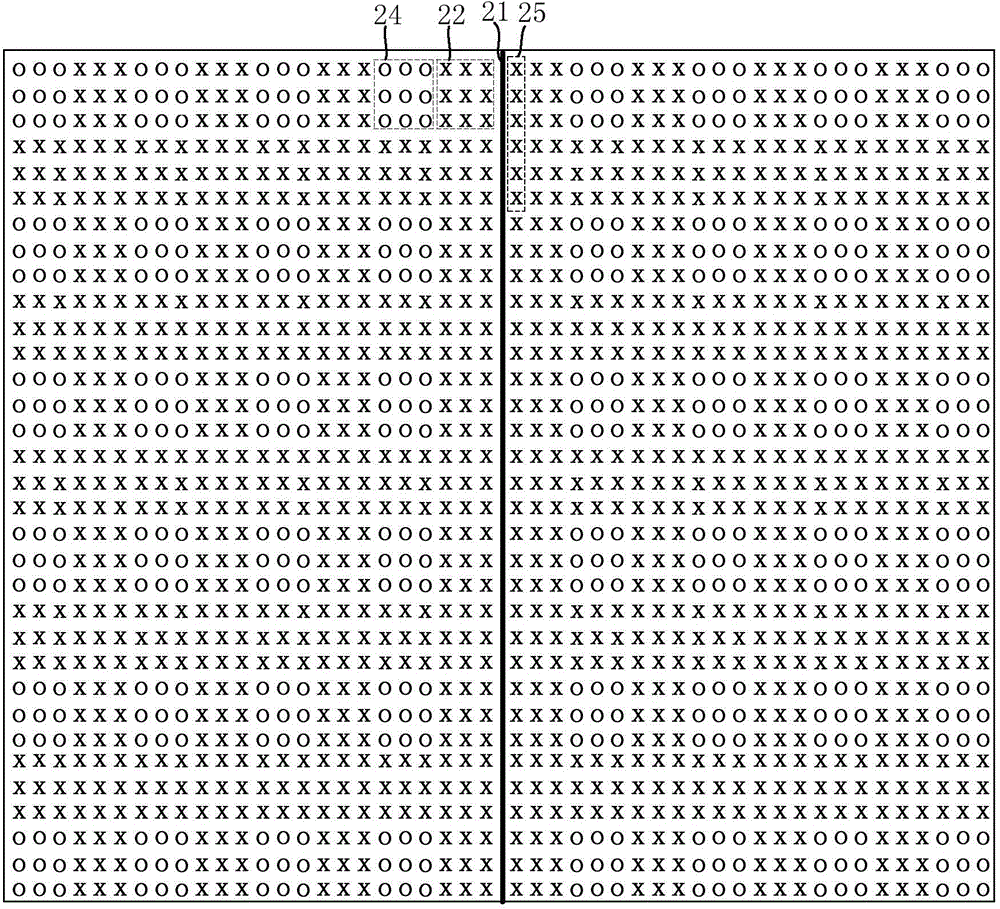

[0034] First, according to the size of the splicing unit of the target LED display, calculate the lighting mode of the screen LED light point of the target LED display, that is, the lighting mode of the screen display unit, because the splicing unit ( figure 2 The size of two adjacent splicing units shown in ) is known (taking a rectangular splicing unit as an example, its size is the number of LED pixels in the row and column direction), so the position of the splicing gap in the captured image can be clearly known. In this embodiment, for each row of display blocks containing bright blocks, for example, on both sides of the splicing between the splicing units, the dark blocks 22, 22, 3×3 display bright blocks...

no. 2 example

[0045] See Figure 7 to Figure 11 The splicing bright and dark line correction method suitable for a spliced display such as an LED display provided by the second embodiment of the present invention can be realized by the following technical solution. specifically:

[0046] First, according to the splicing unit size of the target LED display, calculate the lighting mode of the LED light points of the target LED display screen, that is, the lighting mode of the screen display unit. Since the stitching unit ( Figure 7 The size of two adjacent stitching units shown in ) is known, so the position of the stitching gap in the captured image can be clearly known. In this embodiment, for each row of display blocks containing bright blocks, for example, the mosaic unit on the left side of the mosaic gap 71 displays dark blocks 72 in 5×3 and bright blocks 74 in 3×3 along the direction away from the mosaic gap 71 Arranged alternately, the splicing units on the right side are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com