Spare tire cover plate production technology and mold for spare tire cover plate production technology and spare tire cover plate

A spare tire cover plate and production process technology, which can be applied to household appliances, other household appliances, applications, etc., can solve problems such as easy foaming and weak adhesion, and achieve the goals of saving time, overcoming weak adhesion, and ensuring verticality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

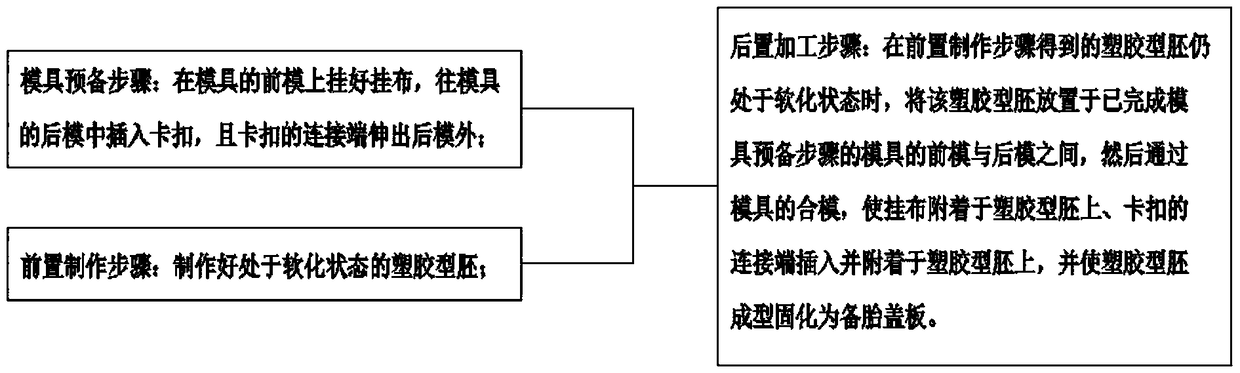

[0029] Such as Figure 1-6 As shown, the production process of the spare tire cover comprises the following steps:

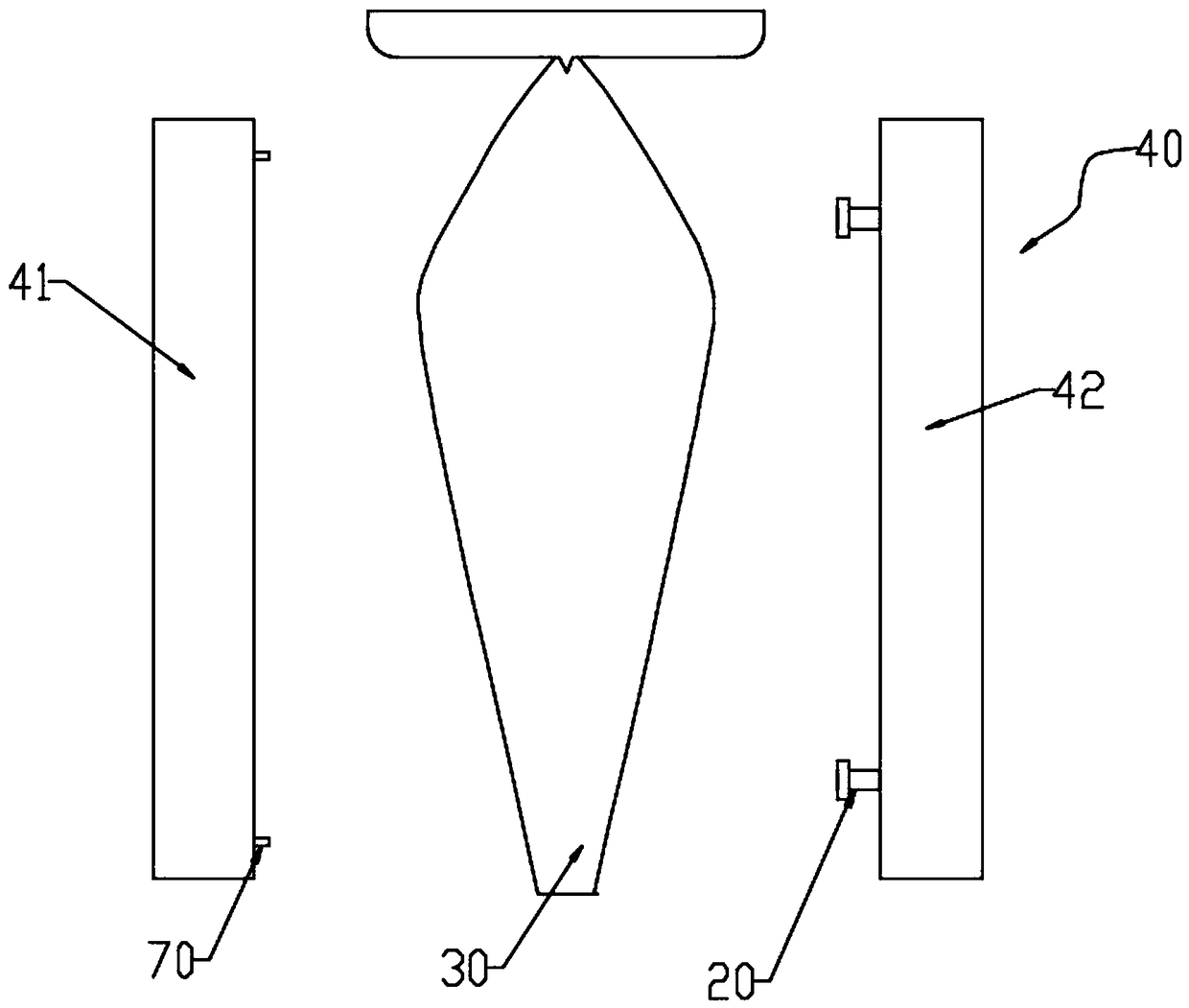

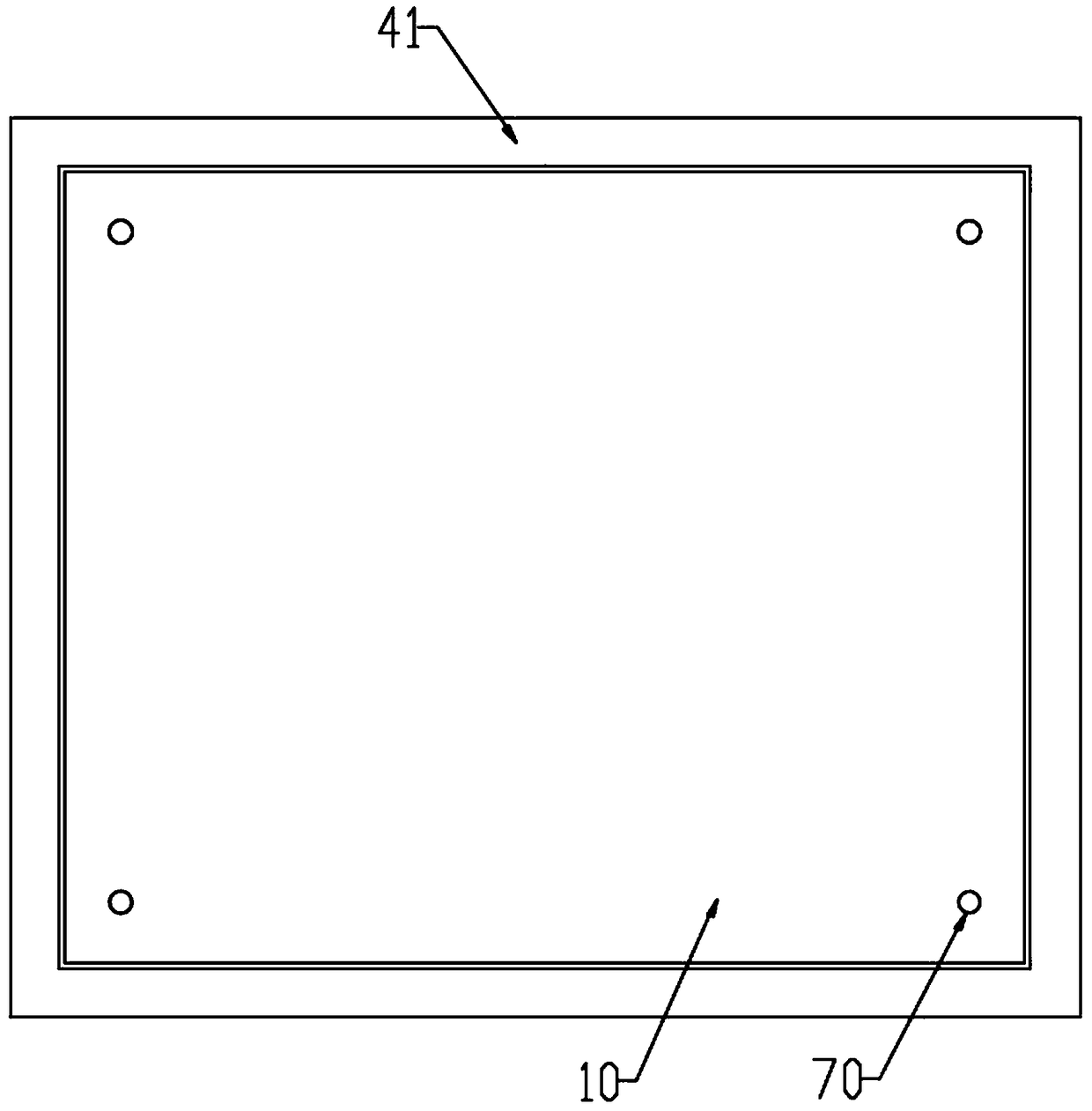

[0030] Mold preparation step: hang the valance 10 on the front mold 41 of the mold 40, insert the buckle 20 into the back mold 42 of the mold 40, and the connecting end 21 of the buckle 20 extends out of the back mold 42;

[0031] Pre-production step: making the plastic parison 30 in a softened state;

[0032] Post-processing step: when the plastic parison 30 obtained in the pre-production step is still in a softened state, the plastic parison 30 is placed between the front mold 41 and the back mold 42 of the mold 40 that has completed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com