Production method for galvanized steel plates

A technology of galvanized steel sheet and production method, which is applied in the field of steel rolling, can solve problems such as difficult to control surface waviness, and achieve the effect of stable solidification and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

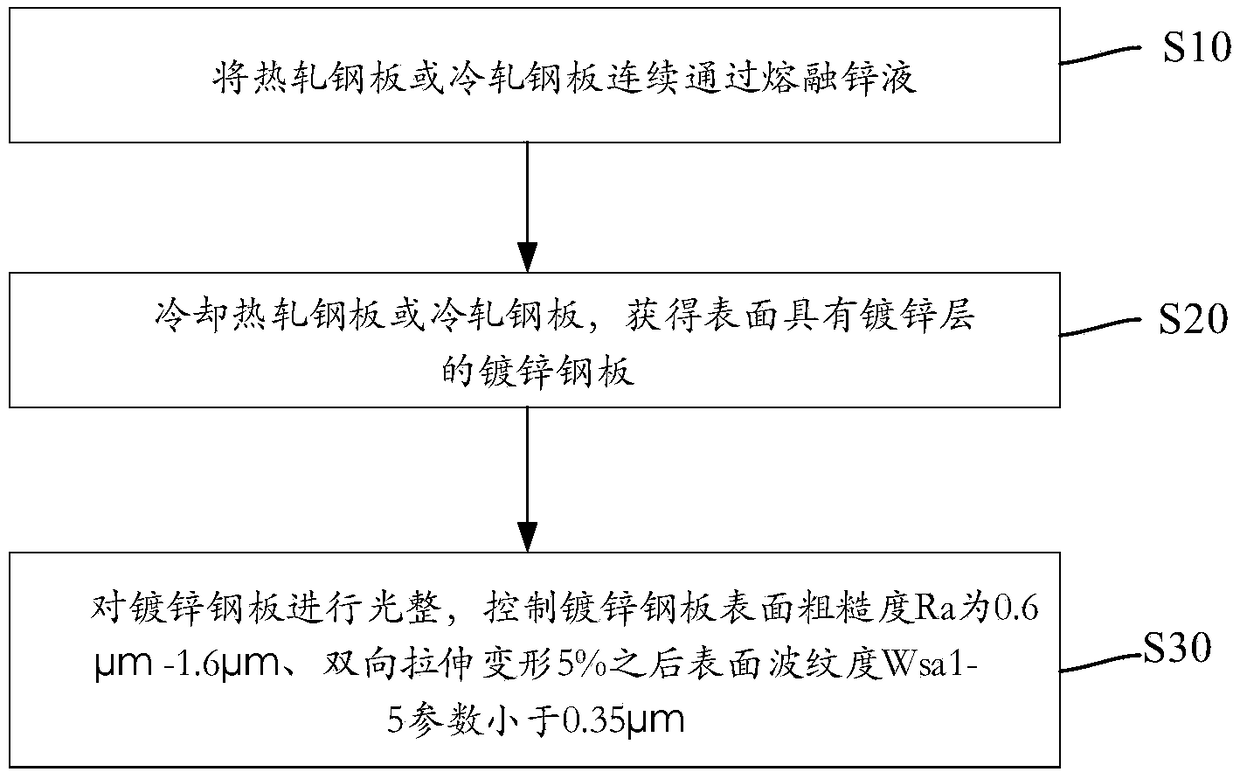

Method used

Image

Examples

specific Embodiment

[0020] In a specific embodiment provided by the present invention, the method further includes: controlling the size of spangles on the surface of the galvanized steel sheet to be less than 300 μm. Preferably, the size of spangles on the surface of the galvanized steel sheet is controlled to be less than 100 μm.

[0021] The size of the concavo-convex topography caused by grain growth competition is small, but it may also reach more than 500 microns. The spangle size is controlled below 300 microns to suppress the increase of waviness caused by grain growth competition. Preferably it should be controlled below 100 microns, the effect is better.

[0022] In a specific embodiment provided by the present invention, the method further includes: controlling the distance between zinc flow lines on the surface of the galvanized steel sheet to be less than 500 μm. Preferably, the distance between zinc flow lines on the surface of the galvanized steel sheet is controlled to be less t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com