A spherical drain water collector for hydraulic mining

A water collector and spherical technology, which is applied in the field of spherical water discharge water collectors, can solve the problems of blockage of spherical water collecting containers, poor water discharge efficiency, small water discharge area, etc., and achieves the effect of reducing blockage and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

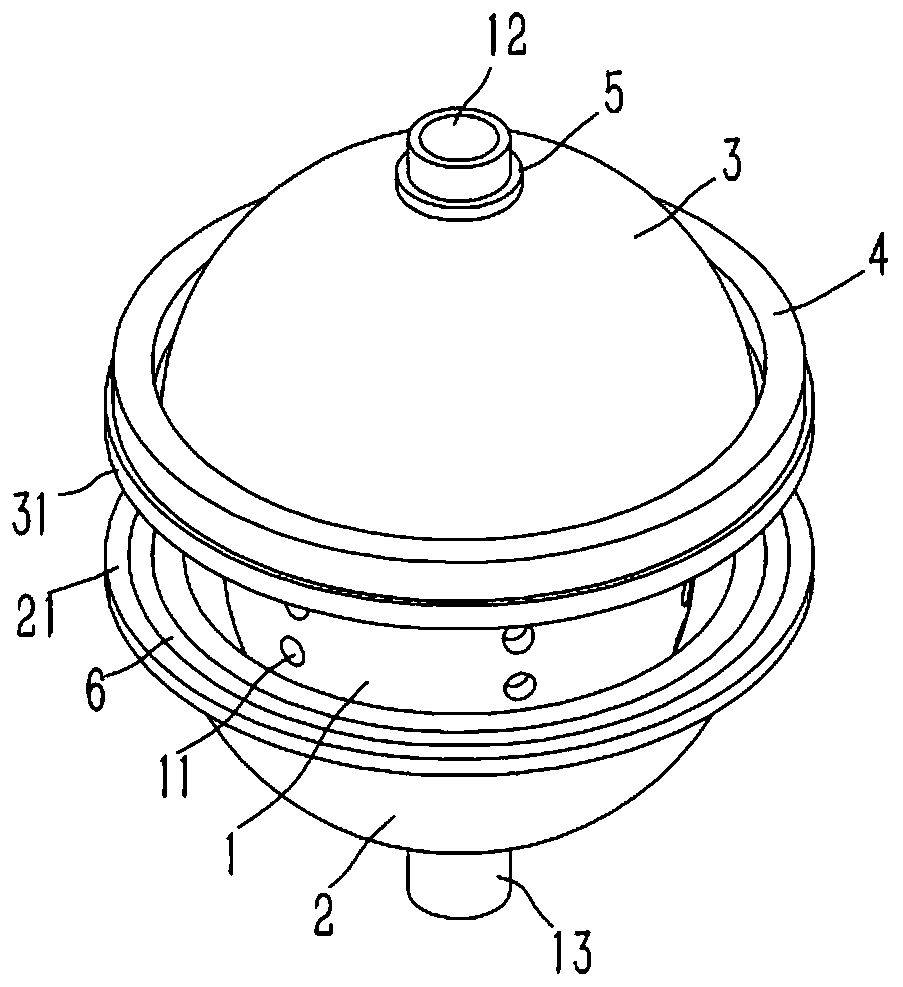

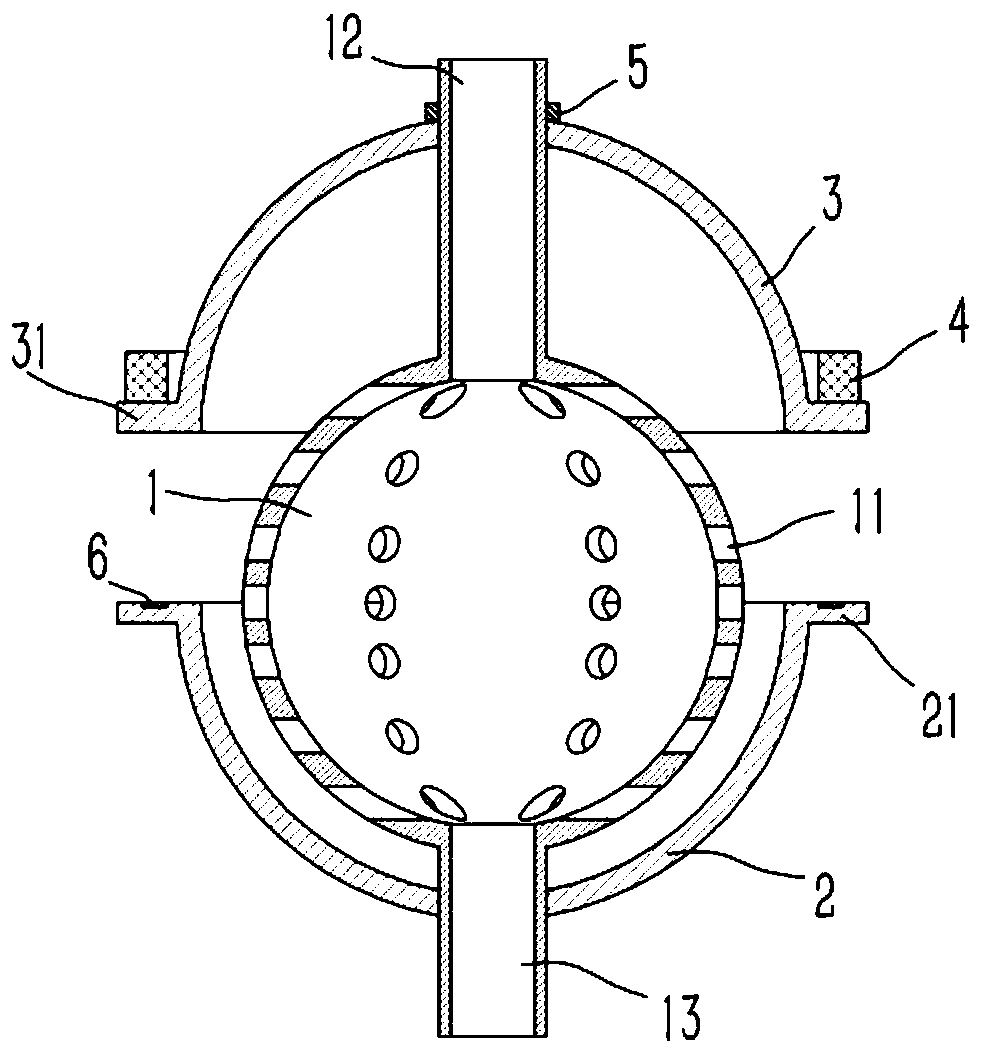

[0015] Example: see figure 1 , 2 As shown, a spherical drainage water collector for hydraulic mining includes a spherical water collector 1, a plurality of drain holes 11 are formed on the water collector 1, and an upper connecting pipe 12 is formed on the top of the water collector 1. , the bottom of the water collector 1 is formed with a lower connecting pipe 13, and the lower connecting pipe 13 is sleeved and fixed with a hemispherical lower casing 2, and the lower casing 2 is inserted and sleeved on the outside of the water collector 1, and the lower casing 2 The upper side is formed with a horizontal annular lower rib 21; the upper connecting pipe 12 is inserted with a hemispherical upper casing 3, the opening of the upper casing 3 faces downward, and the lower side of the upper casing 3 A horizontal annular upper rib 31 is formed, and an annular floating ring 4 is fixed on the upper end surface of the upper rib 31 , and the upper connecting pipe 12 on the upper side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com