Method for automatically sorting and rating metallographic structures of different materials

A metallographic structure and automatic classification technology, applied in the fields of instruments, biological neural network models, character and pattern recognition, etc., can solve the problems of long time, narrow scope of application, time-consuming and labor-intensive, and achieve the effect of improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

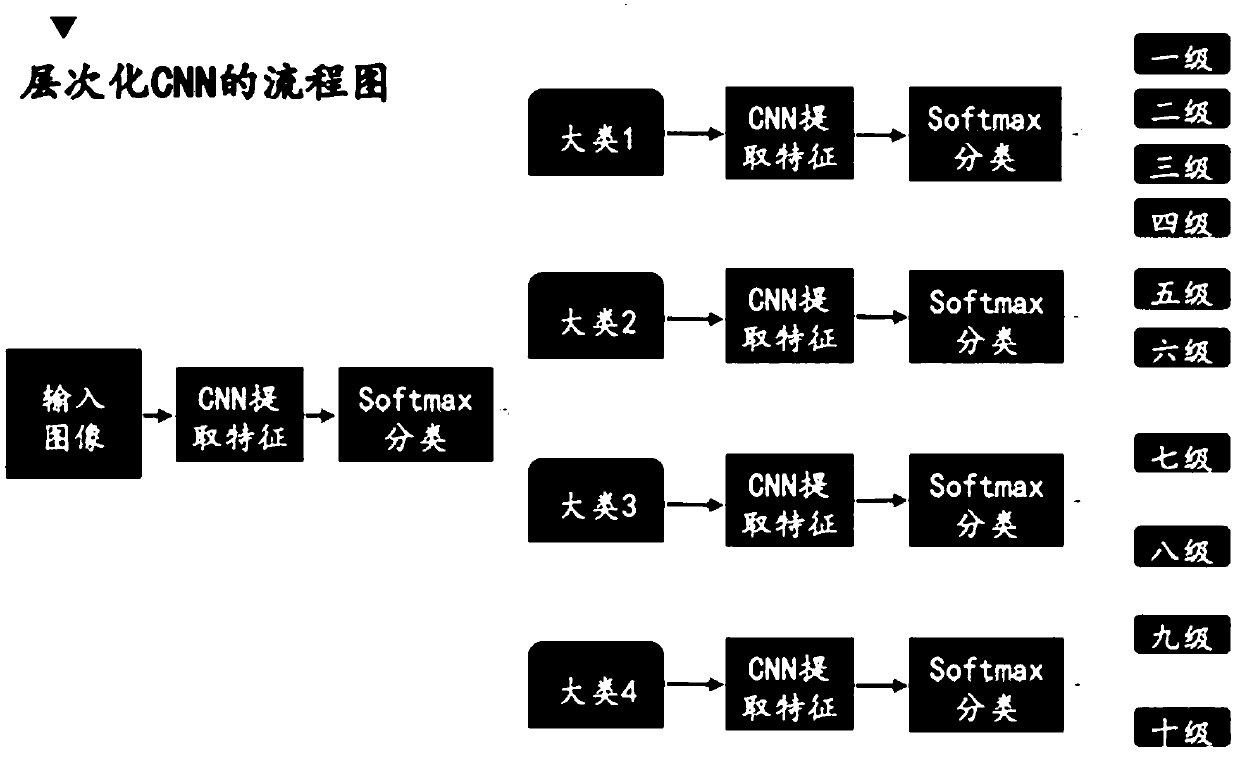

[0078] to combine figure 1 As shown, an automatic classification and rating method for metallographic structures of different materials includes the following steps:

[0079] S1: Establish a database of grain progressions at different multiples for three different materials (20CrMnTi, CF steel and No. 55 steel).

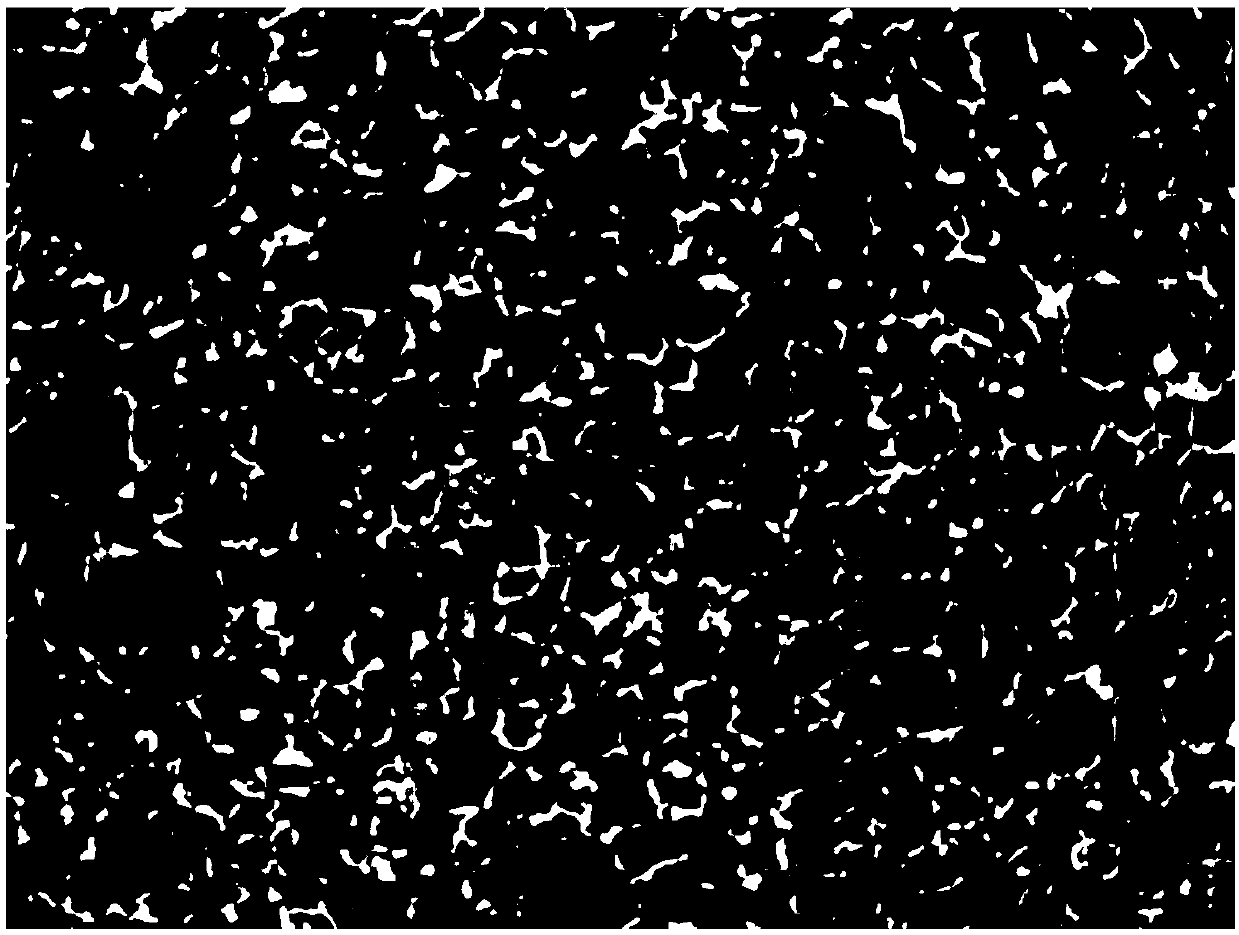

[0080] S2: Read in a metallographic structure image F with a size of M×N, such as figure 2 Shown, wherein: M, N are positive integers;

[0081] S3: Identifying the metallographic material F in the read-in metallographic structure image, including the following steps:

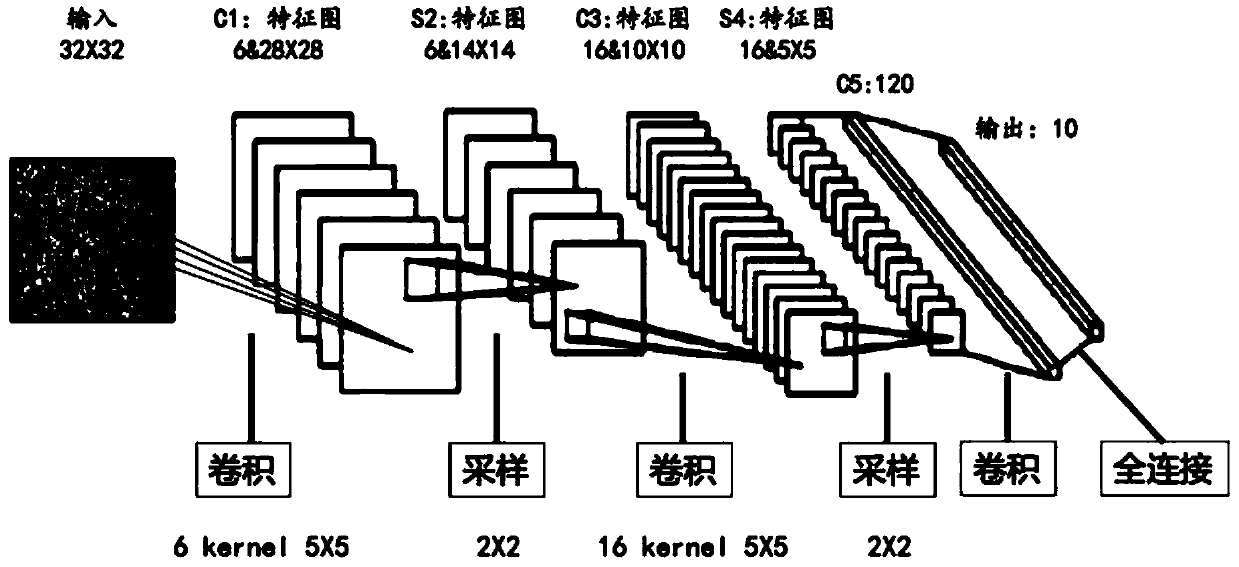

[0082] S3.1: Design a convolutional neural network model, such as image 3 As shown, it includes an input layer, a convolutional layer, an activation function, a downsampling layer and a full...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com