An automatic non-slip tray

An automatic anti-slip and tray technology, applied in the field of life, can solve the problems of soiling customers' clothes, troubles, and insufficient anti-slip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

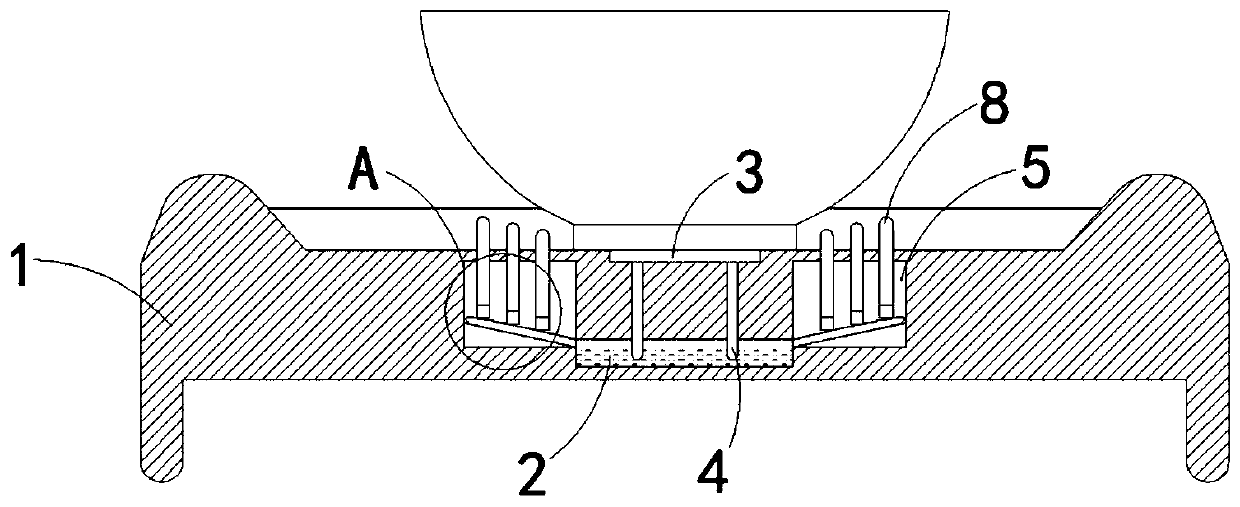

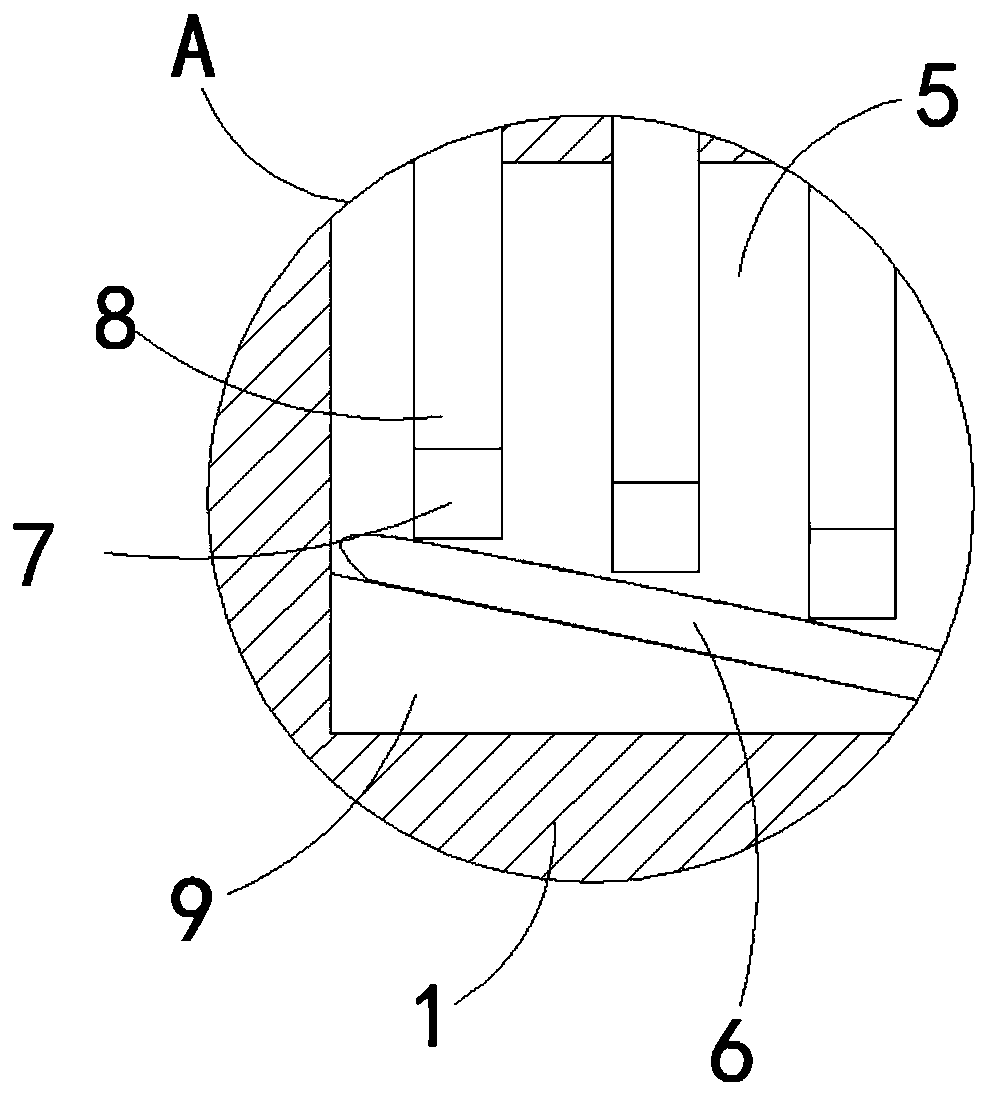

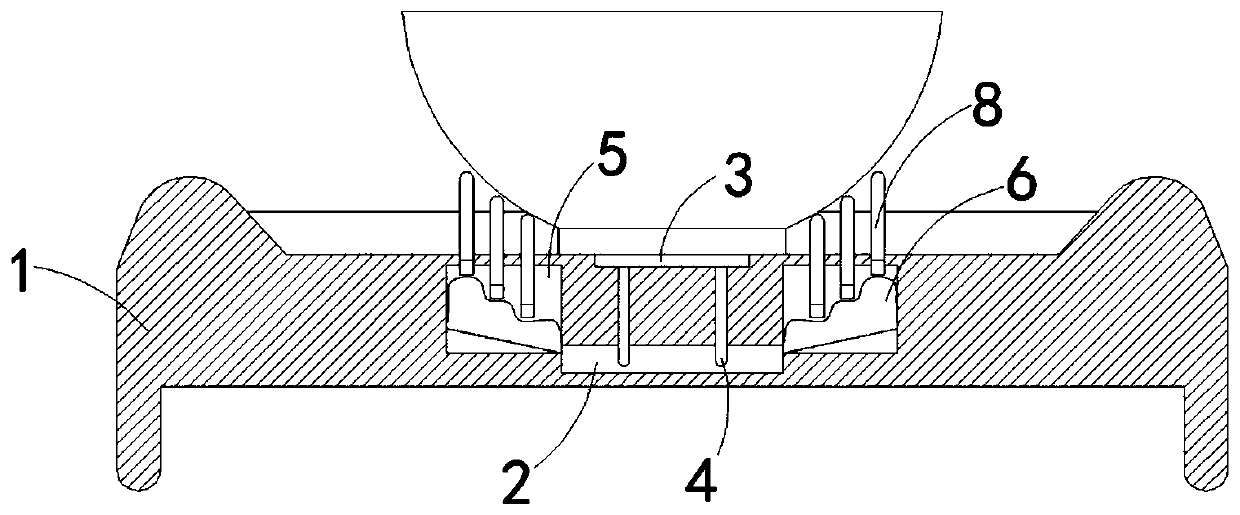

[0019] Such as Figure 1-4 As shown, an automatic non-slip tray includes a tray body 1, a liquid storage chamber 2 is provided in the tray body 1, and the liquid storage chamber 2 is filled with a gasification liquid with a low boiling point, and the boiling point of the gasification liquid is between the normal ambient temperature Between the temperature of the container and the temperature of the container, such as edible vinegar (boiling point is about 40 degrees), the upper end of the tray body 1 is fixedly connected with a heat conduction sheet 3, and the lower end of the heat conduction sheet 3 is fixedly connected with a plurality of heat conduction rods 4, and the lower end of the heat conduction rod 4 extends to In the liquid storage chamber 2, when the vessel is placed on the upper end of the heat conduction sheet 3, the heat generated by the vessel is conducted to the liquid storage chamber 2 by the heat conduction rod 4, and the low-boiling vaporized liquid in the l...

Embodiment 2

[0022] Such as Figure 5 As shown, in this embodiment, cylinders 10 are fixedly connected to the inner side walls of the lower edge of both sides of the tray body 1, and a sealing plug 11 is arranged inside the cylinder 10, and the sealing plug 11 is connected to the lower edge of the tray body 1 by a spring 12. The inner side wall is fixedly connected, the sealing plug 11 is fixedly connected with the pressure rod 13 on the side wall away from the cylinder 10, the lower end of the tray body 1 is fixedly connected with the sealing tube 14, and the two ends of the sealing tube 14 communicate with the two cylinders 10 respectively , the tray body 1 is provided with a U-shaped tube 15, one end of the U-shaped tube 15 communicates with the side wall of the sealed tube 14, and the other end of the U-shaped tube 15 extends into the liquid storage chamber 2 and is located on the top of the liquid storage chamber 2 It is set to prevent liquid from entering the sealed tube 14 as much a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com