Transformer realizing instantaneous boosting and production method of transformer

A production method and transformer technology, applied in the field of transformers, can solve the problems of slow boosting speed and low maximum voltage of step-up transformers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

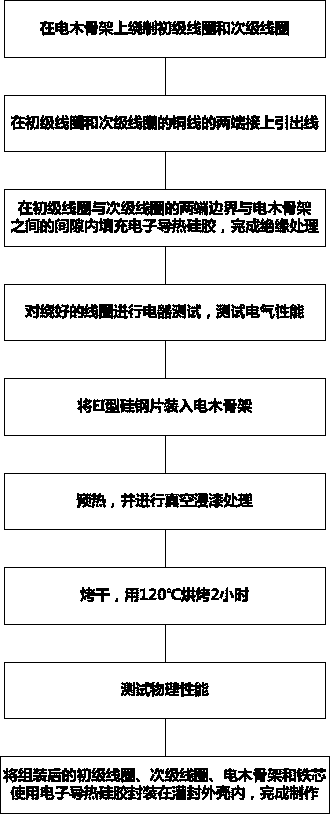

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

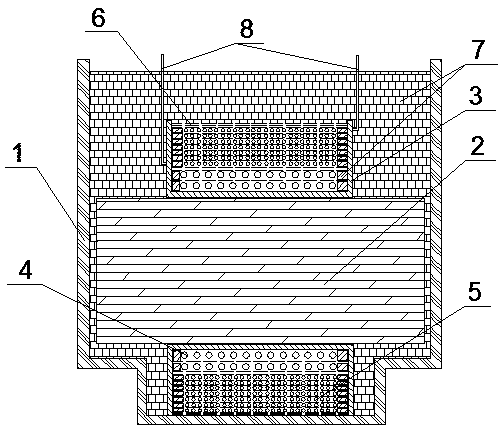

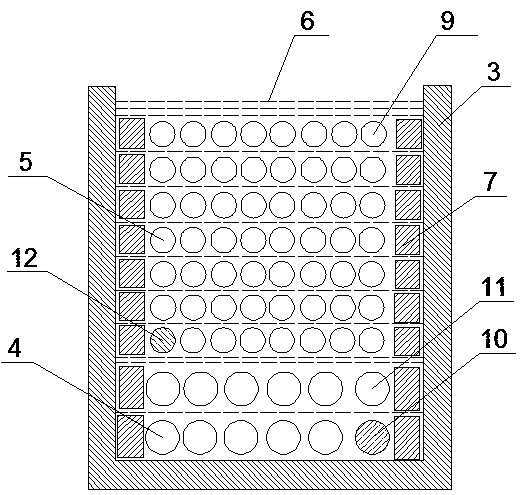

[0029] like figure 1 As shown, a transformer for instantaneous step-up includes a bakelite frame 3, an iron core 2, a potting casing 1, a primary coil 4 and a secondary coil 5, and the primary coil 4 and the secondary coil 5 are wound on On the bakelite frame 3, the iron core 2 is inserted in the middle iron core through hole of the bakelite frame 3, and is perpendicular to the primary coil 4 and the secondary coil 5 wound on the bakelite frame 3, and the assembled primary coil 4, The secondary coil 5, the bakelite frame 3 and the iron core 2 are packaged in the potting shell 1, the coil on the bakelite frame 3 close to the bakelite frame 3 is the primary coil 4, and the outer circumference of the primary coil 4 is secondary The secondary ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap