A kind of cefquinome powder injection

A technology for cefquinoxime and powder injection, which can be used in the field of powder injection and can solve the problems of unstable crystal form, decreased water solubility and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

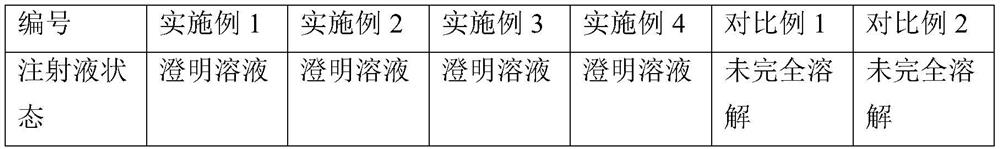

Examples

Embodiment 1

[0020] Recipe: crystalline cefquinoxime: 10 g; polyethylene glycol 4000: 5 g; N-acyl sarcosine: 0.5 g.

[0021] Production process: (1) Melting: Heating polyethylene glycol 4000 to 55 degrees to melt, adding crystalline cefquinoxime and amino acid surfactant, mixing and stirring for 15 minutes. Obtain liquid A.

[0022] (2) Cooling: rapidly cool liquid A to below 15 degrees to obtain solid mixture B.

[0023] (3) Pulverization: The solid mixture B is ultrafinely pulverized.

[0024] (4) Mixing: The pulverized substances were mixed for 30 minutes.

[0025] (5) Sub-packaging: It is enough to sub-pack in a sterile room, and the sub-packaging specification is 1g / piece (calculated by cefquinoxime).

Embodiment 2

[0027] Prescription: crystalline cefquinoxime: 10g; polyethylene glycol 4000: 10g; N-acyl sarcosine: 0.8g

[0028] Production process: (1) Melting: Heating polyethylene glycol 4000 to 55 degrees to melt, adding crystalline cefquinoxime and amino acid surfactant, mixing and stirring for 15 minutes. Obtain liquid A.

[0029] (2) Cooling: rapidly cool liquid A to below 15 degrees to obtain solid mixture B.

[0030] (3) Pulverization: The solid mixture B was mechanically pulverized.

[0031] (4) Mixing: The pulverized substances were mixed for 15 minutes.

[0032] (5) Sub-packaging: It is enough to sub-pack in a sterile room, and the sub-packaging specification is 1g / piece (calculated by cefquinoxime).

Embodiment 3

[0034] Formulation: crystalline cefquinoxime: 10g; polyethylene glycol 4000: 10g; N-acyl sarcosine: 1.2g

[0035] Production process: (1) Melting: Heating polyethylene glycol 4000 to 55 degrees to melt, adding crystalline cefquinoxime and amino acid surfactant, mixing and stirring for 15 minutes. Obtain liquid A.

[0036] (2) Cooling: rapidly cool liquid A to below 15 degrees to obtain solid mixture B.

[0037] (3) Pulverization: The solid mixture B was mechanically pulverized.

[0038] (4) Mixing: The pulverized substances were mixed for 15 minutes.

[0039] (5) Sub-packaging: It is enough to sub-pack in a sterile room, and the sub-packaging specification is 1g / piece (calculated by cefquinoxime).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com