Shaft type adjustable camera support

A camera and shaft-type technology, which is applied in the direction of machines/brackets, supporting machines, magnetic objects, etc., can solve the problems that users are difficult to adjust the angle, the size of the camera is small, and the infinite adjustment cannot be realized, so that it is not easy to radially shift, Eliminate the effect of back-moving, circumferential relative position stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

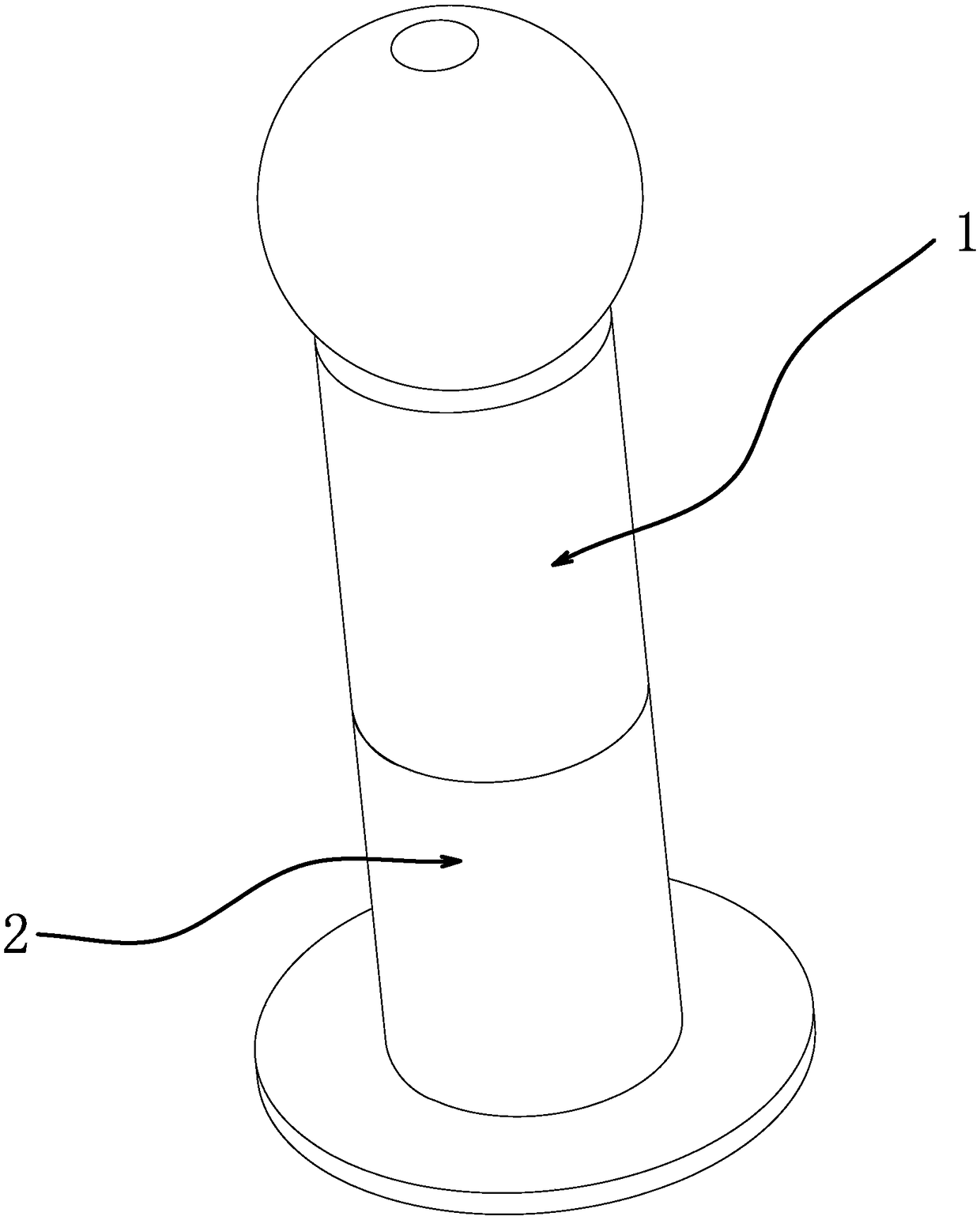

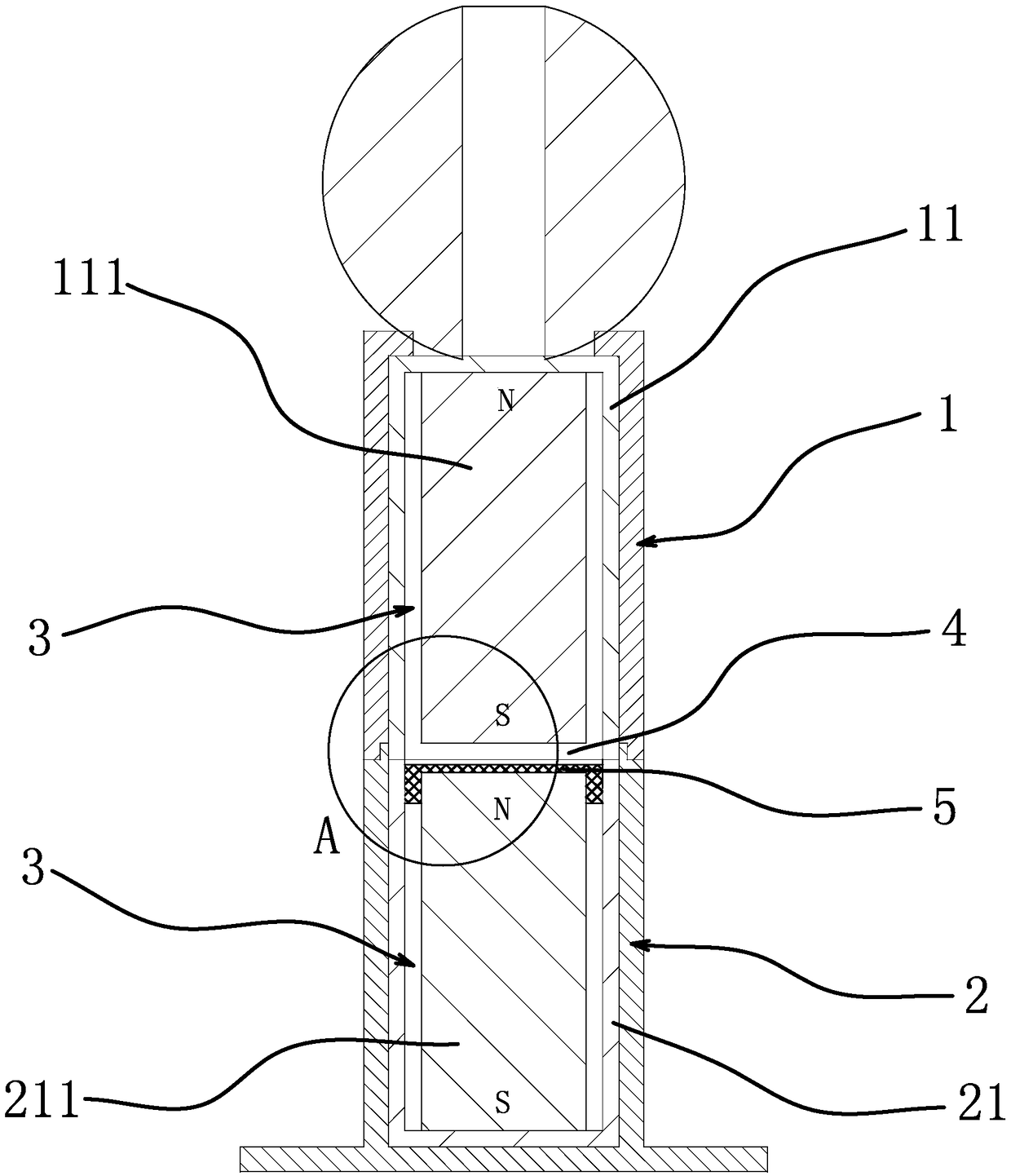

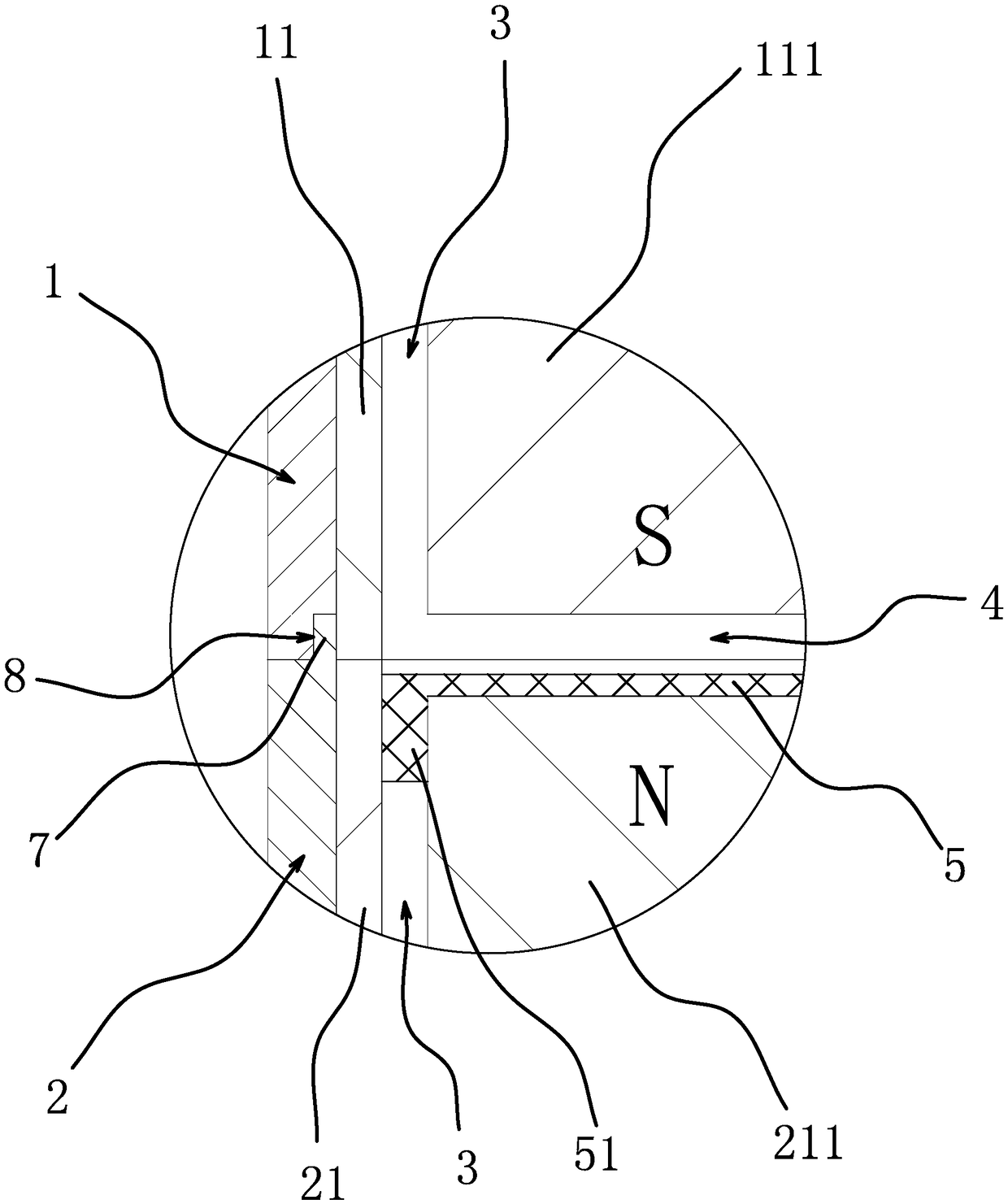

[0030] Such as Figure 1-4As shown, the shaft-type adjustable camera bracket includes an upper shaft 1 and a lower shaft 2 arranged axially opposite each other. The lower end surface of the upper shaft 1 is in close contact with the upper end surface of the lower shaft 2. Rotate in the vertical direction, the upper end surface of the lower shaft 2 and the lower end surface of the upper shaft 1 are respectively embedded with a magnetic conduction bowl 1 21 and a magnetic conduction bowl 2 11 which are axially oppositely arranged, and the open end surface of the magnetic conduction bowl 1 21 It abuts against the open end face of the magnetic conduction bowl 2 11 and forms a seal. A cylindrical permanent magnet 211 is coaxially fixed inside the magnetic conduction bowl 1 21, and a cylindrical permanent magnet 211 is coaxially fixed inside the magnetic conduction bowl 2 11. The second permanent magnet 111, the second permanent magnet 111 and the first permanent magnet 211 are coax...

Embodiment 2

[0033] Such as Figure 5 As shown, the present embodiment is basically the same as the first embodiment, except that: in the shaft-type adjustable camera bracket, the top surface of the permanent magnet 1 211 is in close contact with the permanent magnet 2 111 . By arranging the first permanent magnet 211 and the second permanent magnet 111 to be in close contact, the maximum axial force can be achieved, the connection and the direct alignment effect between the upper shaft 1 and the lower shaft 2 can be ensured, and the damping in the adjustment process can be increased to facilitate precise adjustment. Epoxy resin 6 is poured in the annular space 3, the permanent magnet one 211 is fixedly connected with the magnetic conduction bowl one 21 through the epoxy resin 6, and the permanent magnet two 111 is fixedly connected with the magnetic conduction bowl two 11 through the epoxy resin 6. By pouring epoxy resin 6 in the annular space 3, the axial and radial positions of permanen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com