Single-screw carbon fiber mechanical lifting rod

A carbon fiber, lifting rod technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

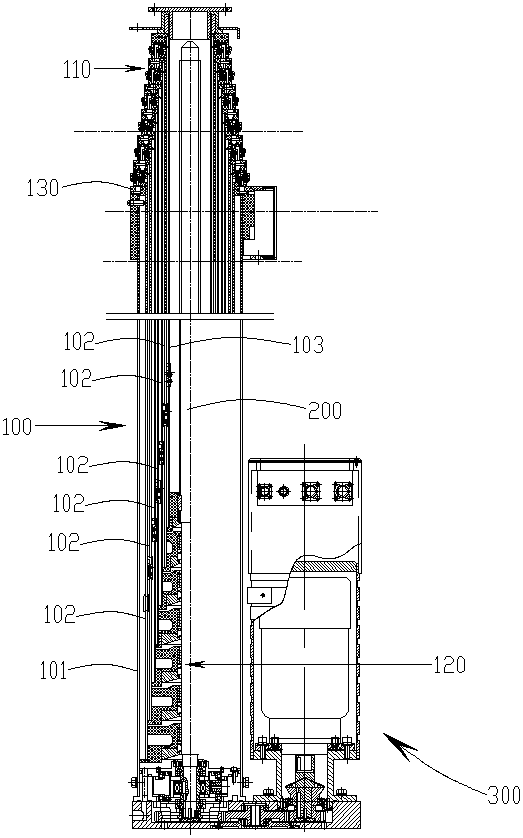

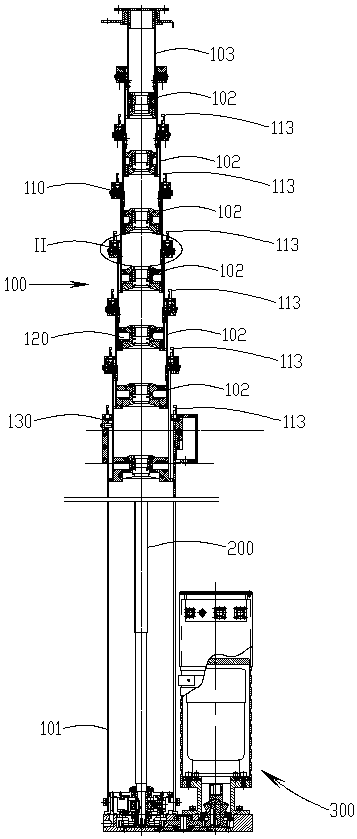

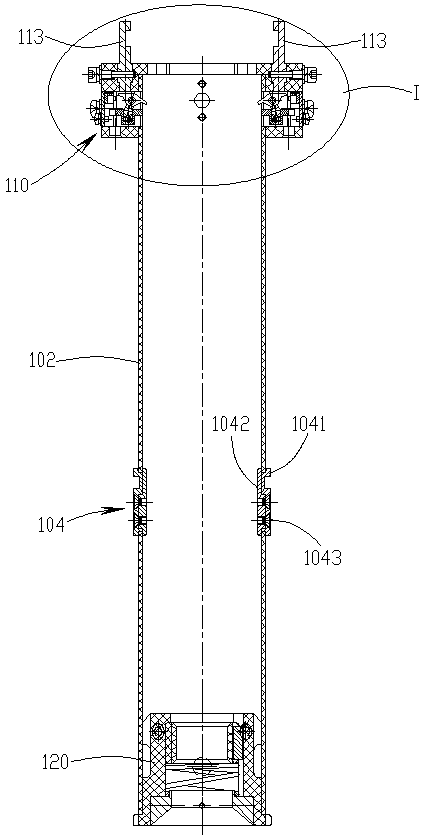

[0046] see figure 1 - Figure 28 , the single-screw carbon fiber mechanical lifting rod of the present invention includes a carbon fiber tube body 100, a lead screw 200 and a driving device 300 for driving the lead screw to rotate. The carbon fiber top tube 103 on the inner side and a plurality of carbon fiber inner tubes 102 located between the bottom tube and the top tube are composed of a circular lock seat 110, a top tube and the lower end of each inner tube outside the upper end nozzle of each inner tube. There is a silk nut sleeve 120 in the nozzle, and an annular upper sleeve 130 is installed outside the upper nozzle of the bottom tube. The left and right sides of the annular lock seat 110 are respectively provided with radial lock cavities 111. Correspondingly, The wall of the inner tube has a lock hole 1021 that communicates with the lock cavity. A lock sleeve 112 is embedded in the lock cavity. The lock sleeve has a lock sleeve baffle 1121 and two pieces perpendicul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com