Mold for making continuous wall and method for making continuous wall with the same

A technology of mold and mold components, which is applied in the field of molds for making continuous walls, can solve the problems of inability to realize horizontal connections and cannot produce horizontal connection continuous walls, etc., so as to improve the strength and waterproof effect, improve the adaptability, and improve the degree of automation Effect

Active Publication Date: 2019-07-09

周兆弟

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this device cannot be used to achieve horizontal connections, nor can it be used to produce continuous walls that can be connected horizontally.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

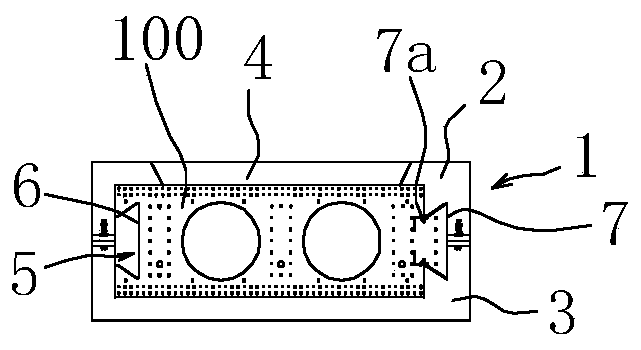

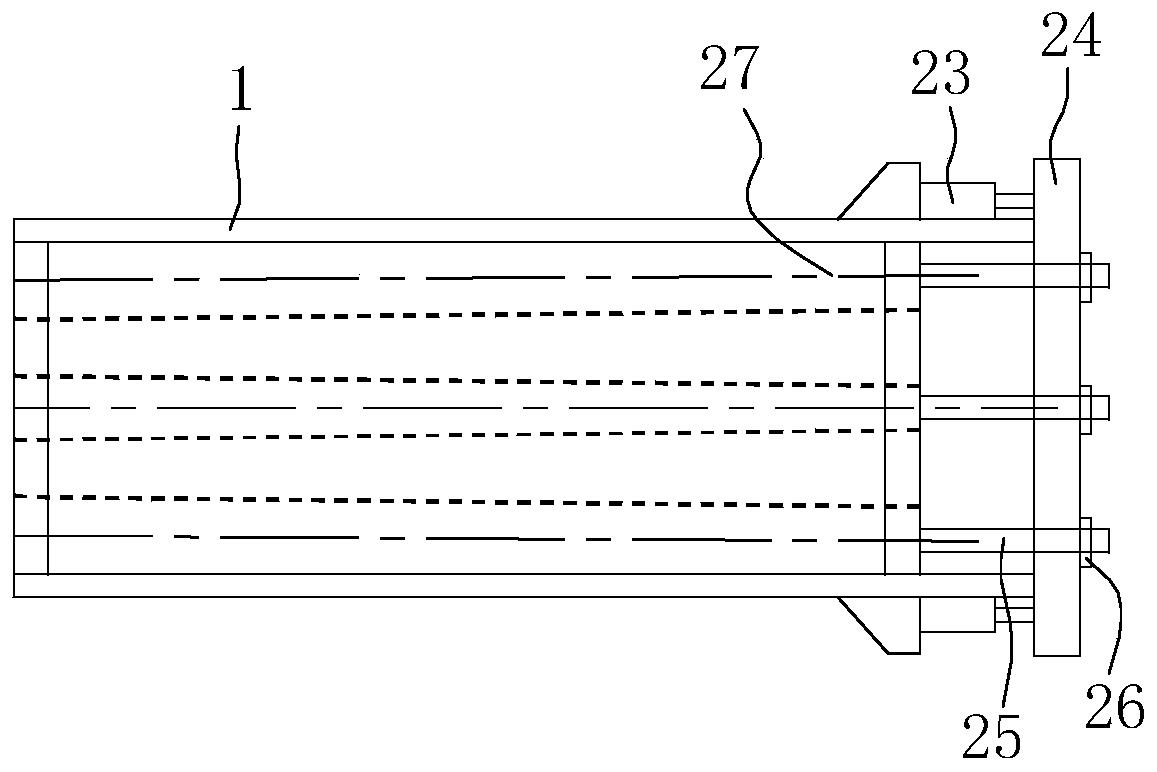

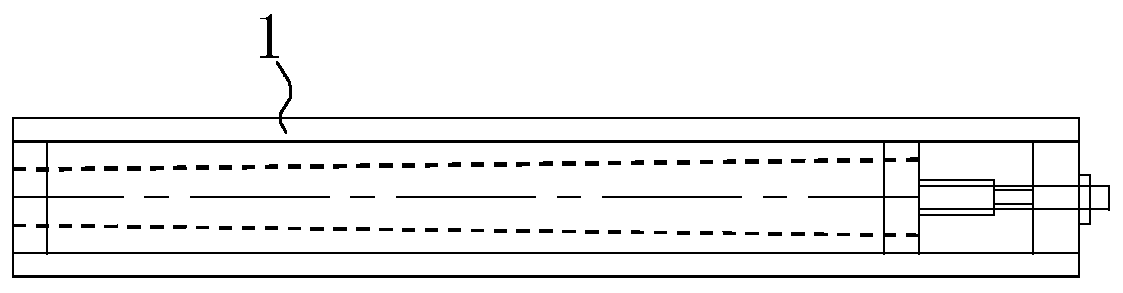

Login to View More Abstract

The invention belongs to the technical field of construction and relates to a mold for making a continuous wall and a method for making the continuous wall through the mold. The mold comprises a mold body. The mold body comprises an upper mold assembly and a lower mold assembly which are detachably connected. A material distribution opening mechanism for material distribution is arranged on the mold body. A waterproof bayonet mechanism is arranged in the mold body, wherein the waterproof bayonet mechanism is capable of being fixedly connected with the continuous wall in the mold body so that concave-convex waterproof connecting structures can be formed on the two sides of the continuous wall. The mold is simple in structure and convenient to use and is capable of being opened and closed conveniently, and accordingly the production efficiency can be improved.

Description

technical field The invention belongs to the technical field of construction, and relates to a mold for making a continuous wall and a method for making a continuous wall with the mold. Background technique The continuous wall is a continuous wall constructed by using drilling equipment to form a groove section. It has a large structural rigidity and can play a good supporting role. It is suitable for various geological conditions and can be used as a part of the main body of the underground building, saving The project cost is reduced, the construction procedure is simplified, the functions are diverse, and the construction pollution is small. Diaphragm walls were first applied in Italy. In the 1950s, Italy first adopted pile-row underground diaphragm walls. Then it was rapidly promoted in the west, and it was quickly applied in France and Germany in 1954; in 1959, it was extended to Japan and achieved great development. Japan is currently the country with the most applic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B28B7/42B28B11/24B28B13/06B28B23/00B28B23/02B28B23/04

CPCB28B1/14B28B7/0002B28B7/0011B28B7/0014B28B7/42B28B11/245B28B13/065B28B23/00B28B23/02B28B23/043

Inventor 周兆弟

Owner 周兆弟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com