Substrate suction stage, substrate treatment apparatus, and substrate treatment method

A substrate processing method and adsorption table technology, which can be used in manufacturing tools, metal processing, laser welding equipment, etc., and can solve problems such as chip cracking, chip not being separated from the workbench, and reduced yield of qualified products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

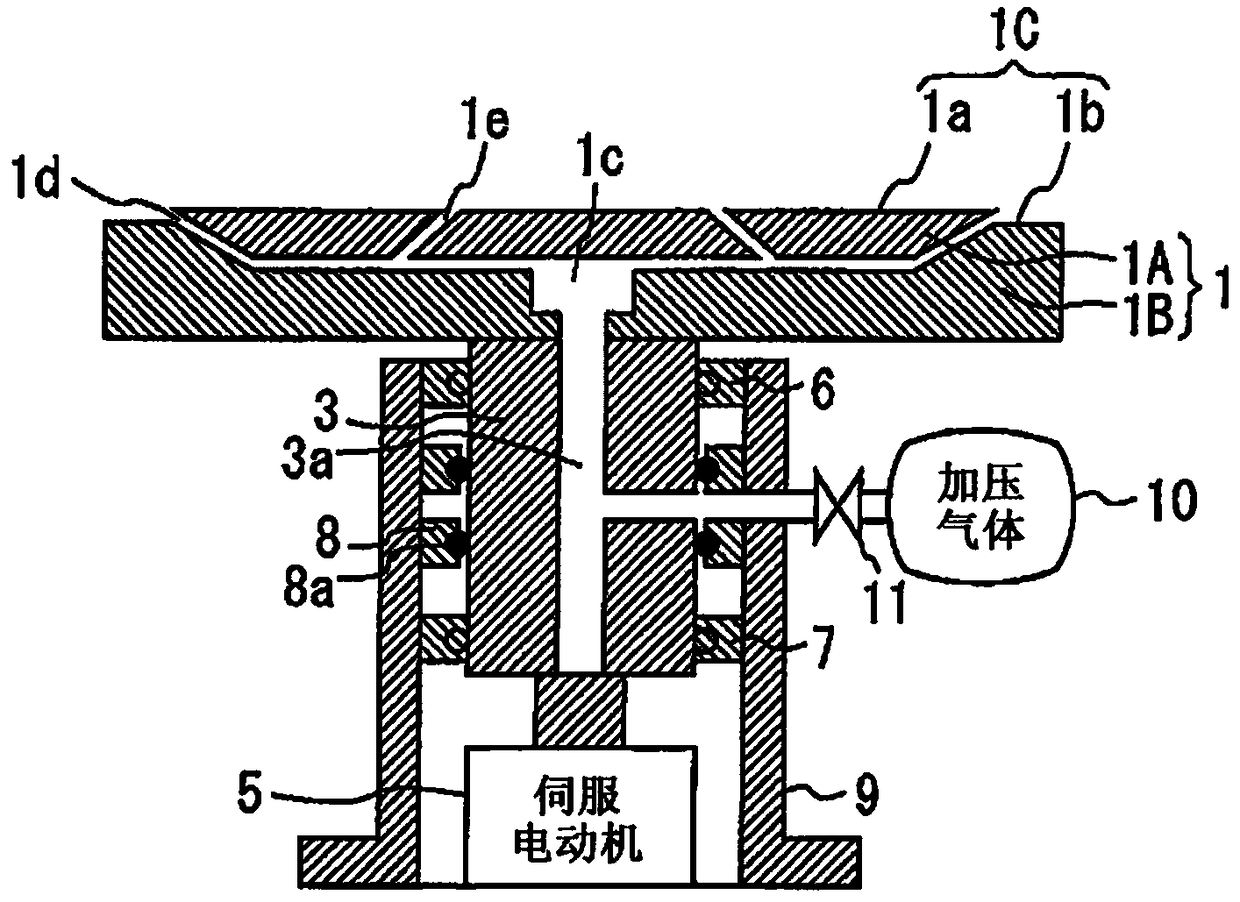

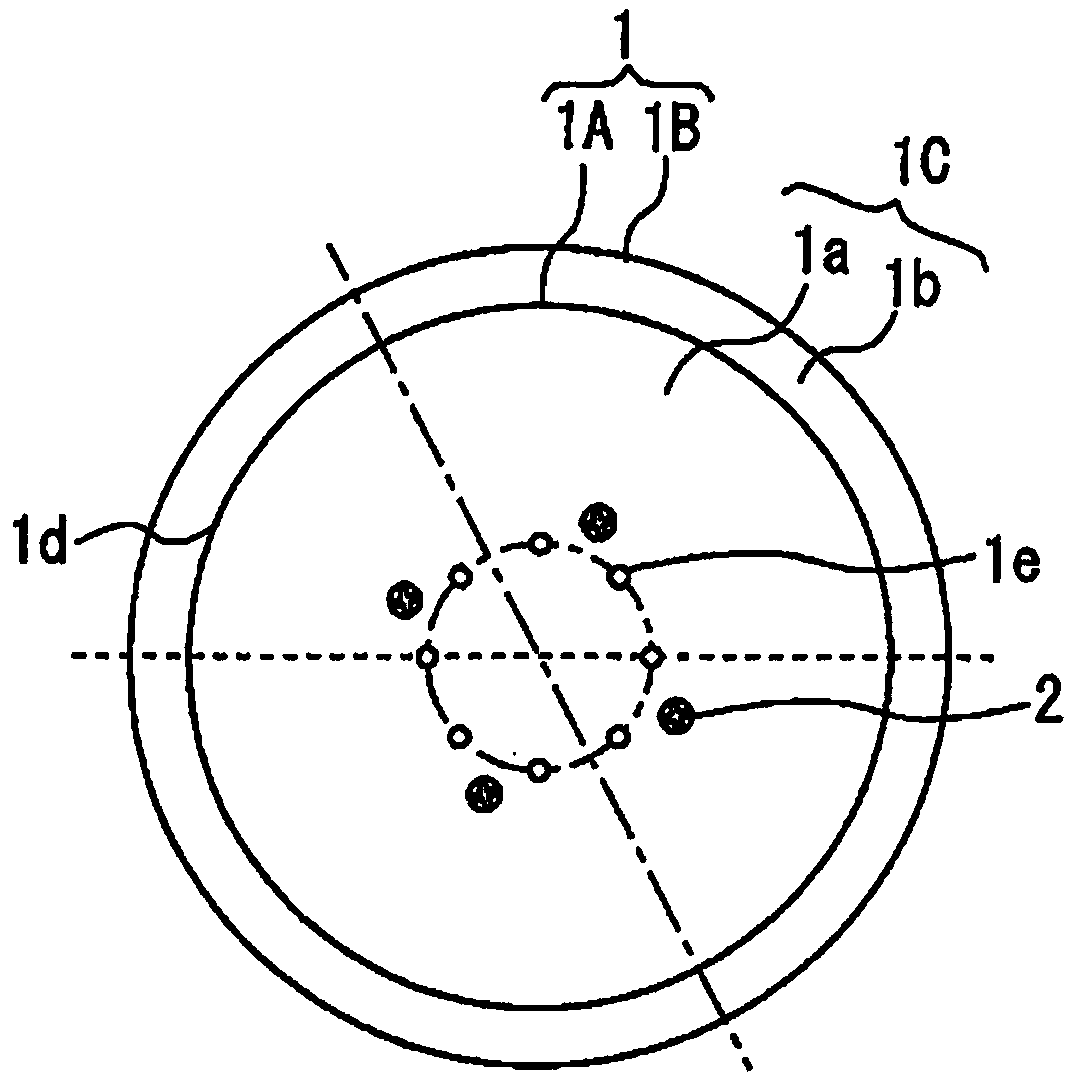

[0033] figure 1 It is a cross-sectional view of the substrate suction table according to Embodiment 1. The substrate suction table includes a substrate support unit 1 that supports a substrate. The substrate supporting part 1 has an upper surface 1C. The upper surface 1C includes a first upper surface 1a and a second upper surface 1b formed lower than the first upper surface 1a. A cavity 1c is formed inside the substrate support portion 1 . The cavity 1c is located substantially in the center of the substrate support portion 1 .

[0034] In the substrate supporting part 1, a discharge hole 1d extending from the cavity 1c to the upper surface 1C and an adsorption hole 1e connecting the discharge hole 1d to the upper surface 1C are formed. The discharge hole 1d is connected to the cavity 1c, and is also connected to the stepped portion between the first upper surface 1a and the second upper surface 1b. The adsorption hole 1e is formed in the first upper surface 1a. The ads...

Embodiment approach 2

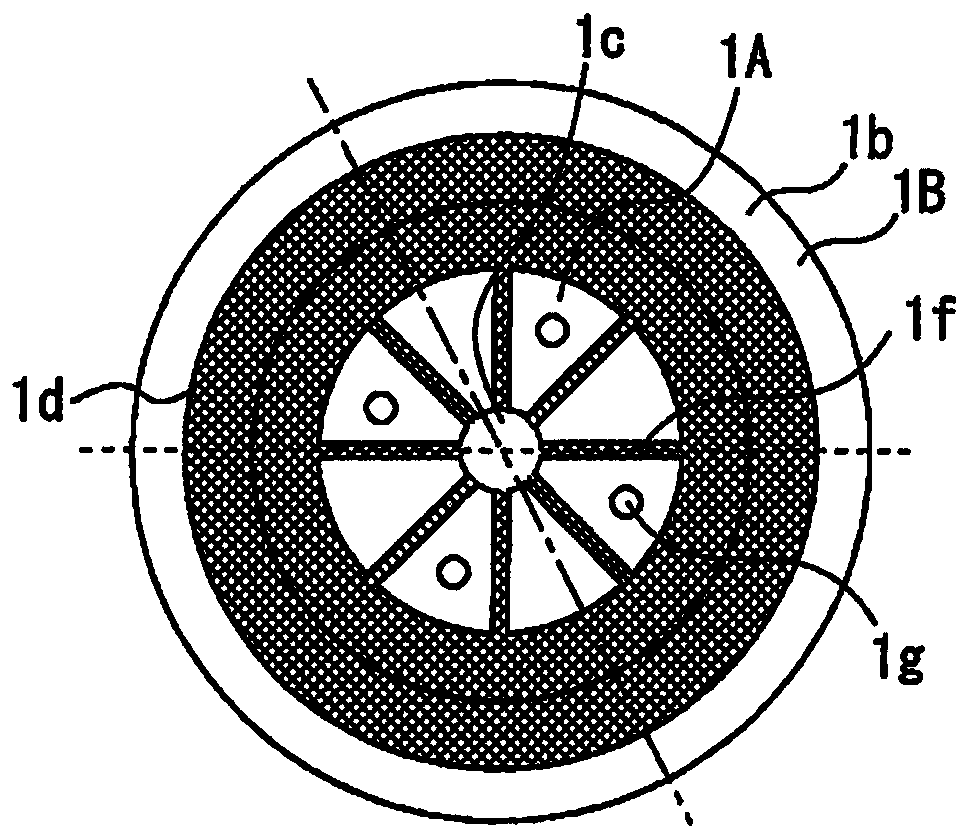

[0055] Figure 10 It is a plan view of the second part 1B according to Embodiment 2. The second portion 1B of the substrate supporting portion 1 is formed in a circular shape in plan view. Figure 10 The shape of the slot 1i of part 2 1B with image 3 The slot 1f is different. The groove 1i is linear in a region close to the cavity 1c, but is formed in a curved line in a region far from the cavity 1c. According to this curved portion, a component advancing in a tangential direction to the outer edge of the second portion 1B can be given to the airflow ejected from the ejection hole 1d.

[0056] Figure 11 It is a diagram showing the flow of gas inside and outside the discharge hole 1d when the pressurized gas is supplied to the cavity 1c by arrows. The direction of the arrow 46 indicates the traveling direction of the gas ejected from the ejection hole 1d, and the length of the arrow 46 indicates the velocity of the gas. In addition, the curve 46a represents the velocity...

Embodiment approach 3

[0061] Figure 13 It is a cross-sectional view of the substrate suction table according to Embodiment 3. The first portion 1A of the substrate support unit 1 includes a spacer 50 . Below the partition 50 there is a part of the discharge hole 1d, and above the partition 50 there is an adsorption hole 1e. The adsorption hole 1e is composed of a parallel flow path 1k connected to the discharge hole 1d and extending parallel to the discharge hole 1d, and a connecting flow path 1j connecting the parallel flow path 1k with the substrate support portion 1. 1C connection on the upper surface. The parallel flow path 1k has a region on the side of the cavity 1c and a region on the outer edge side of the substrate supporting part 1 . The area on the outer edge side is connected to the discharge hole 1d, and the area on the cavity 1c side is connected to the connection channel 1j.

[0062] Figure 14 It is a plan view of the substrate suction table according to Embodiment 3. Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com