The construction method of the non-stop production bump opening of the pipeline under pressure

A technology of pipeline and construction method, applied in the field of pipeline docking construction, can solve the problems of inconvenient replacement of the hole opener, inconvenient repositioning of the hole opener, etc., to reduce the risk of repeated construction, improve the service life, and ensure the effect of sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

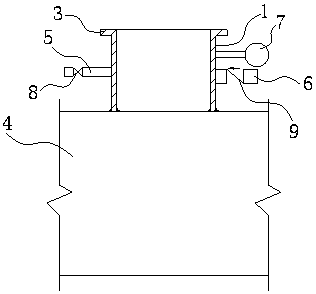

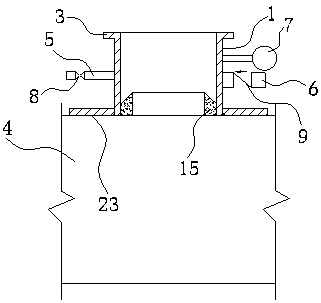

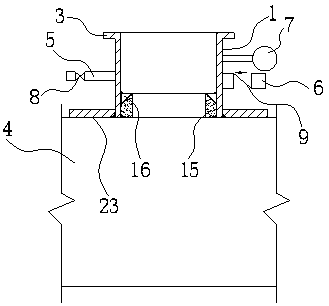

[0041] Combine Figure 1-7 The shown construction method for the non-stop production of the pressurized pipelines includes the following steps: when preparing for work, since the pipes encountered are all pressurized and in working conditions, adequate safety precautions should be taken depending on the location of the bump. In the position below the ground, it is necessary to do well in anti-collapse work of potholes, and to do well in anti-fall protection for aerial operations. It is best to build a firm operating platform.

[0042] A. Welding of short pipe 1 with flange:

[0043] Select the joint position on the main pipe 4 according to the design requirements, weld a short pipe 1 at the joint position, one end of the short pipe 1 is provided with a first flange 3 for connecting with the gate valve 2, and the other end of the short pipe 1 is welded to the main pipe 4 above; the inner diameter of the short tube 1 usually needs to be greater than the design reaming size by more t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com