Novel heat exchange tube plate

A heat exchange tube, a new type of technology, applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of low heat transfer efficiency and heat rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

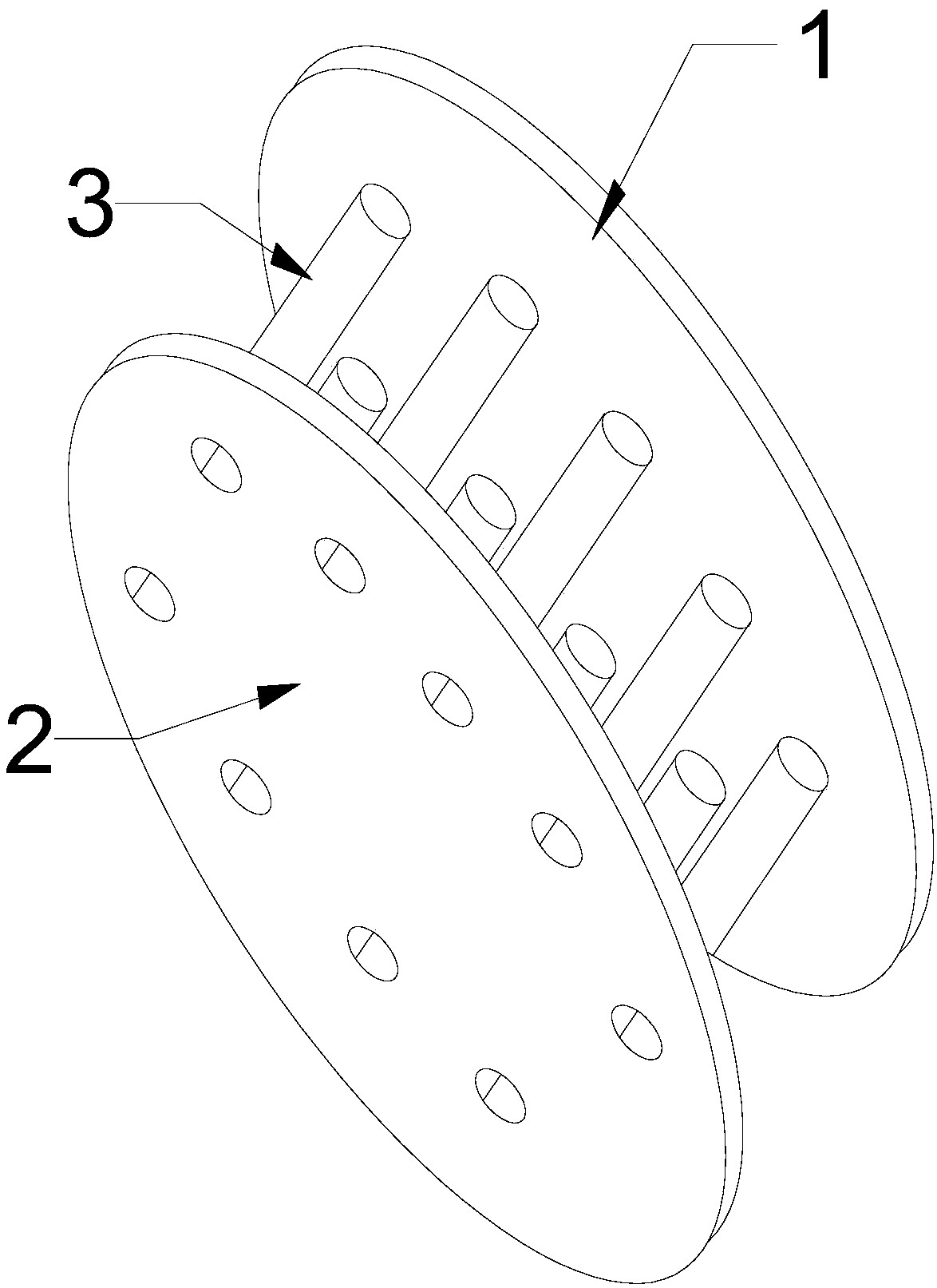

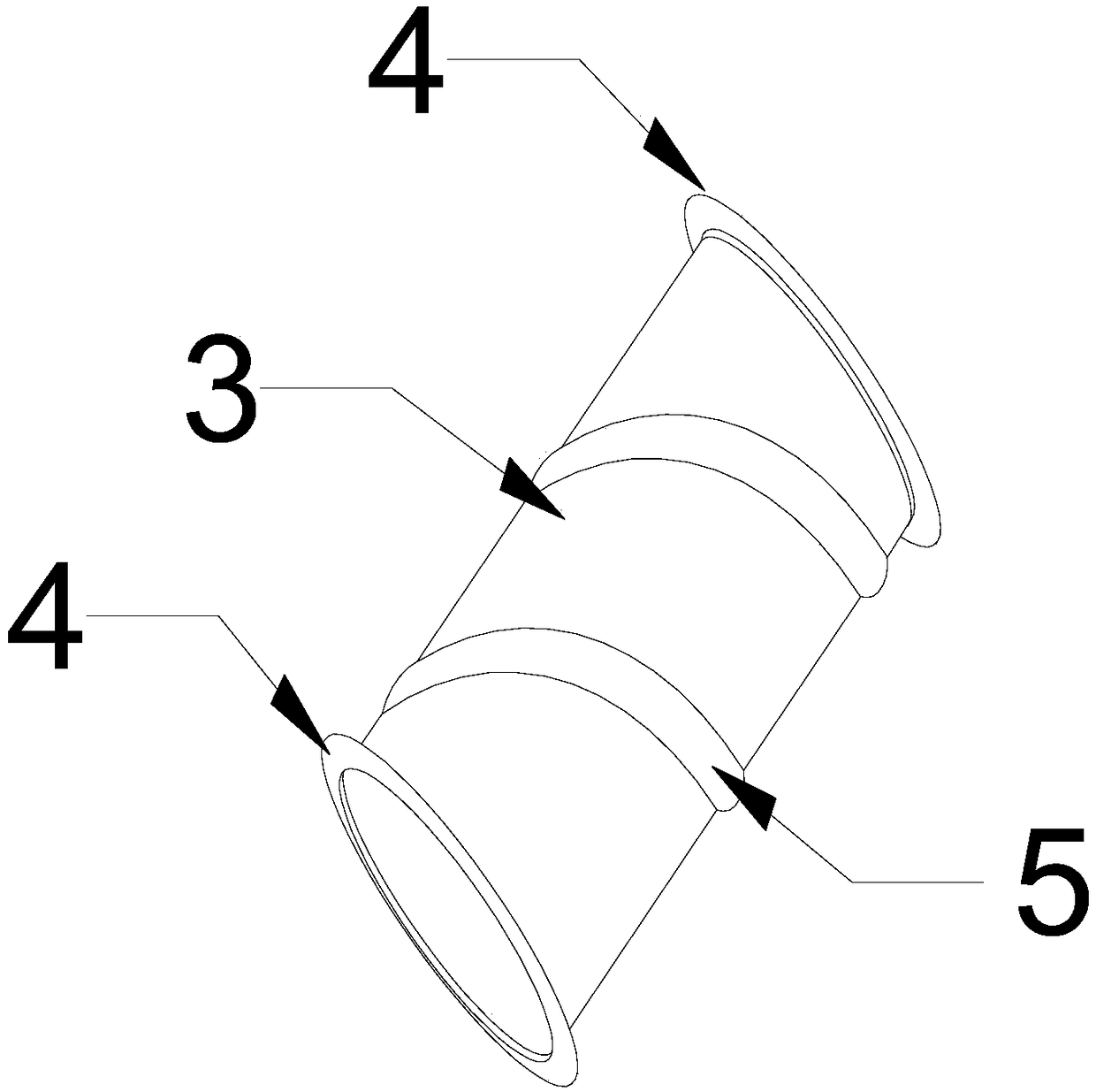

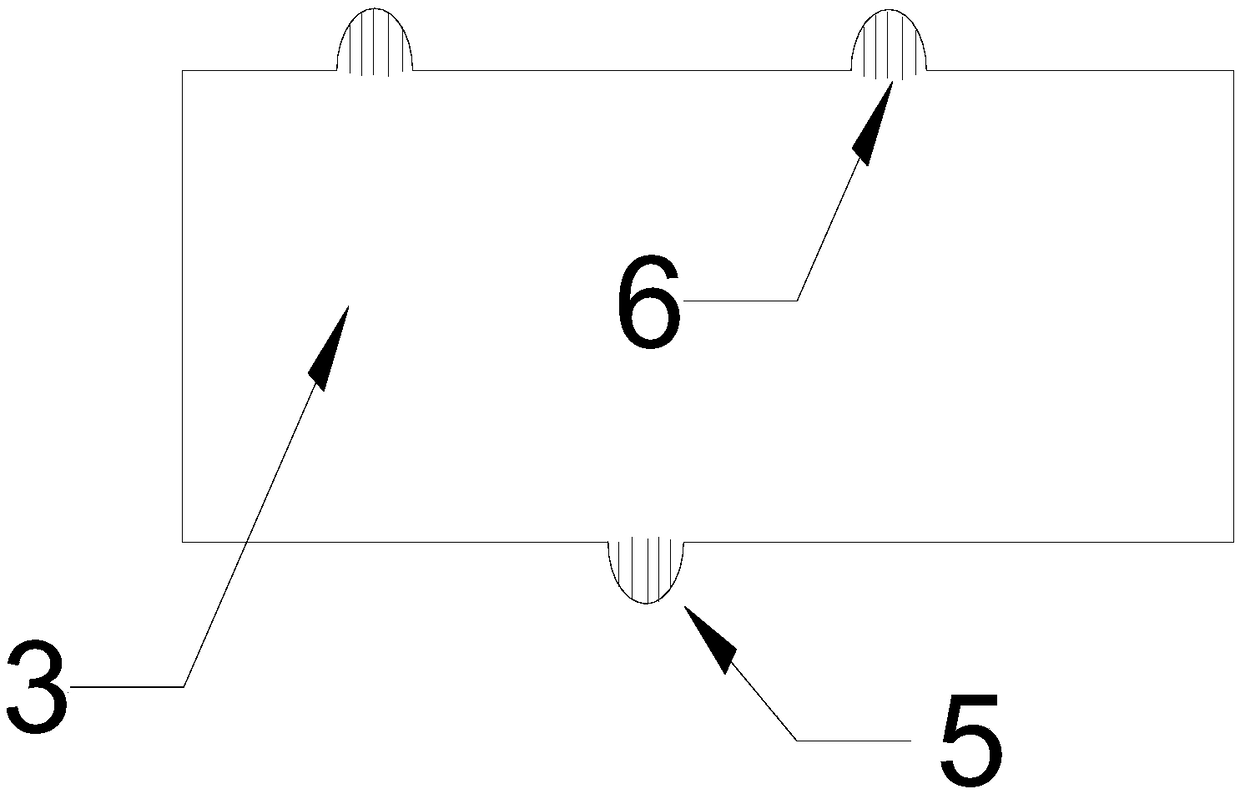

[0015] A new type of heat exchange tube plate, including A plate 1 and B plate 2, said A plate and B plate are circular panels, and arranged in parallel, there is also a pipe fitting 3 between A plate and B plate, so The two ends of the pipe fittings are provided with sheet baffles 4, the two ends of the pipe fittings penetrate through the A board and the B board, and the sheet baffles are close to the surfaces of the A board and the B board, and the pipe fittings The pipe wall is provided with a helical protrusion 5, and the helical protrusion and the pipe wall are integrally formed.

[0016] A plurality of parallel heat conduction strips 6 are also provided in the inner cavity of the spiral protrusion, one end of the heat conduction strip 6 is connected to the inner wall of the spiral protrusion 5, and the other end is flush, and does not exceed the tube wall. the horizontal plane at.

[0017] Through the above-mentioned structure, when the pipe is inserted into the pipe fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com