Overturning machine for cleaning castings and detecting conveying line

A casting cleaning and conveying line technology, which is applied in the field of turning machines, can solve the problems of non-floor cleaning, non-floor cleaning and testing, and reduce casting hoisting and handling, so as to achieve the effects of improving production efficiency, safe and reliable use, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

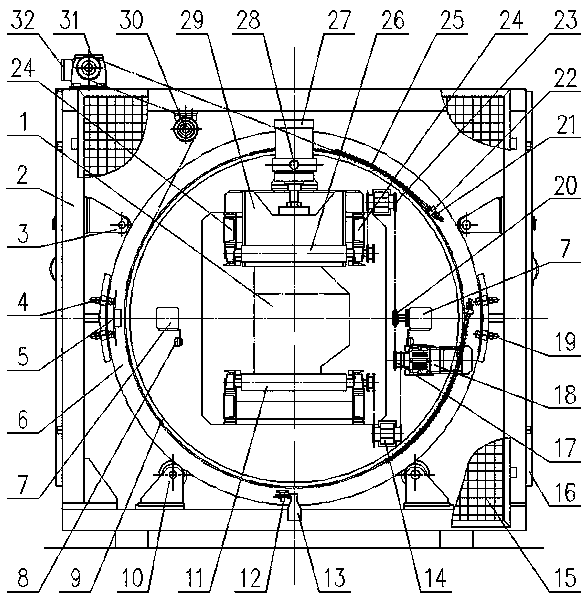

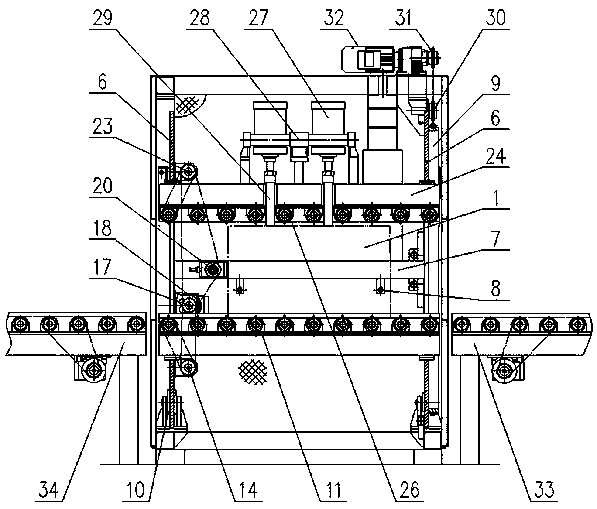

[0020] Referring to the accompanying drawings, the specific implementation is as follows:

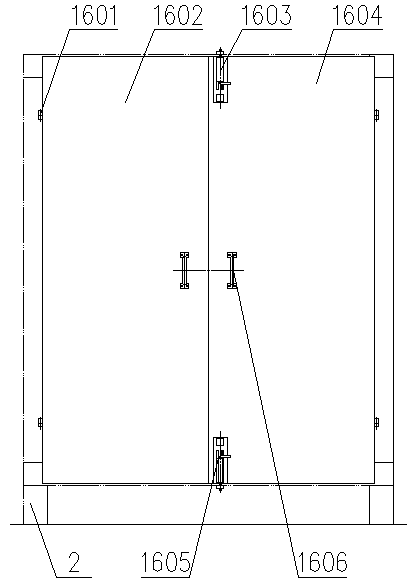

[0021] A turning machine for casting cleaning and detection conveyor line, comprising a frame 2 and two rotating discs 6, two pairs of supports for respectively supporting the two rotating discs 6 are installed on the frame 2 Wheel 10, described supporting wheel 10 all can freely rotate around self central axis and the central axes of all supporting wheels 10 are all parallel to each other, and the outer circumference of all supporting wheels 10 is provided with the wheel groove that matches with rotating disk 6, The wheel grooves of the two supporting wheels 10 of the same pair are relatively arranged, and the outer circumferences of the two rotating disks 6 are respectively pressed on the bottom of the wheel grooves of the pair of supporting wheels 10, so that the two rotating disks 6 can be wound around themselves. The central axis rotates freely and the central axes of the two rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com