A flipping and pouring machine for casting cleaning and testing conveyor lines

A casting cleaning and conveying line technology, which is applied to the processing device of used abrasives, manufacturing tools, abrasives, etc., can solve the problems of reducing casting hoisting and handling, prone to safety accidents, high labor intensity, etc., and achieves improved cleaning methods , Satisfy the effect of automatic production of castings and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

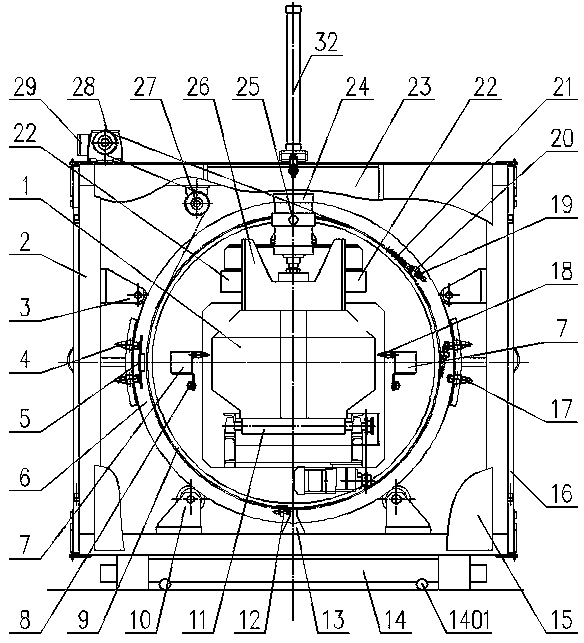

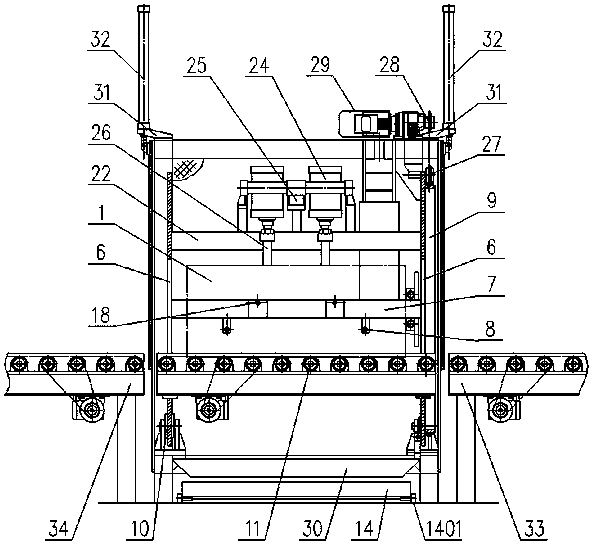

[0022] With reference to the drawings, the specific implementation is as follows:

[0023] An overturning and inverting shot machine for casting cleaning and inspection conveyor line, comprising a frame 2 and two rotating discs 6, on which two pairs are installed for supporting the two rotating discs 6 respectively The supporting wheel 10 can be freely rotated around its central axis and the central axes of all supporting wheels 10 are parallel to each other, and the outer circumference of all supporting wheels 10 is provided with a wheel matching the rotating disc 6 The grooves of the two supporting wheels 10 of the same pair are arranged oppositely, and the outer circumferences of the two rotating discs 6 are respectively pressed on the bottom of the grooves of the pair of supporting wheels 10, so that the two rotating discs 6 can Rotate freely around its own central axis and the central axes of the two rotating discs 6 coincide, and the two ends of the rotating disc 6 are clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com