Floating support device

A floating support and support column technology, applied in positioning devices, supports, clamping and other directions, can solve the problems of unreliable support and clamping of parts and unreliable support of support points, and achieves ingenious structure, accurate support and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

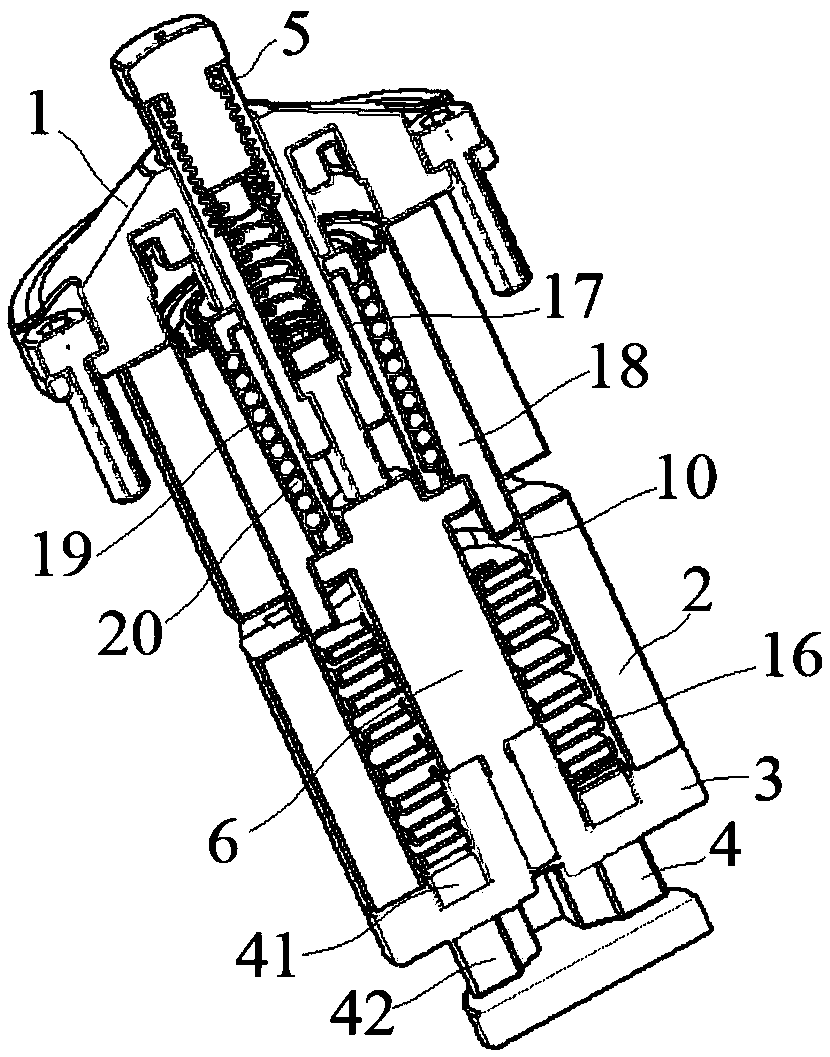

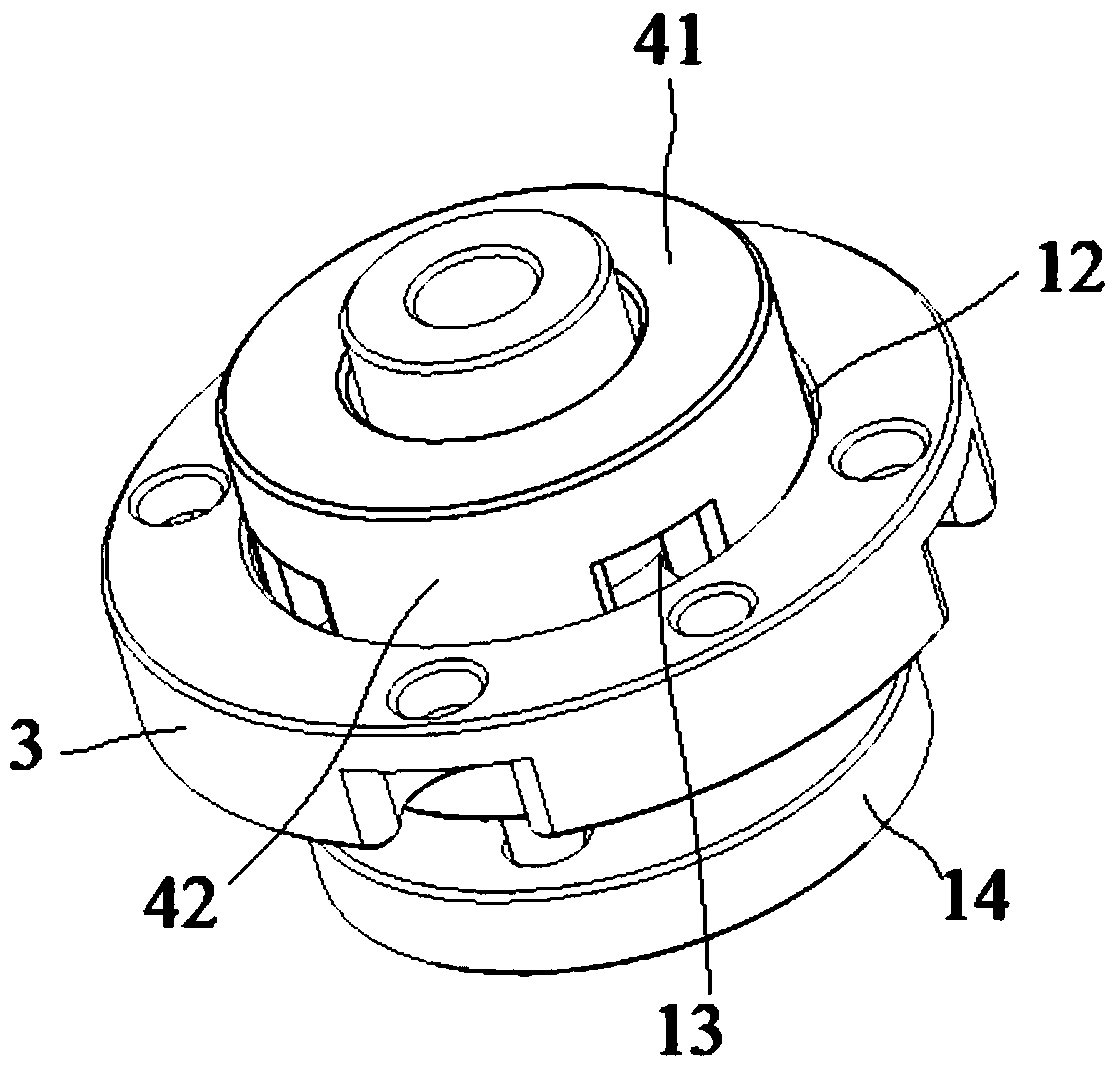

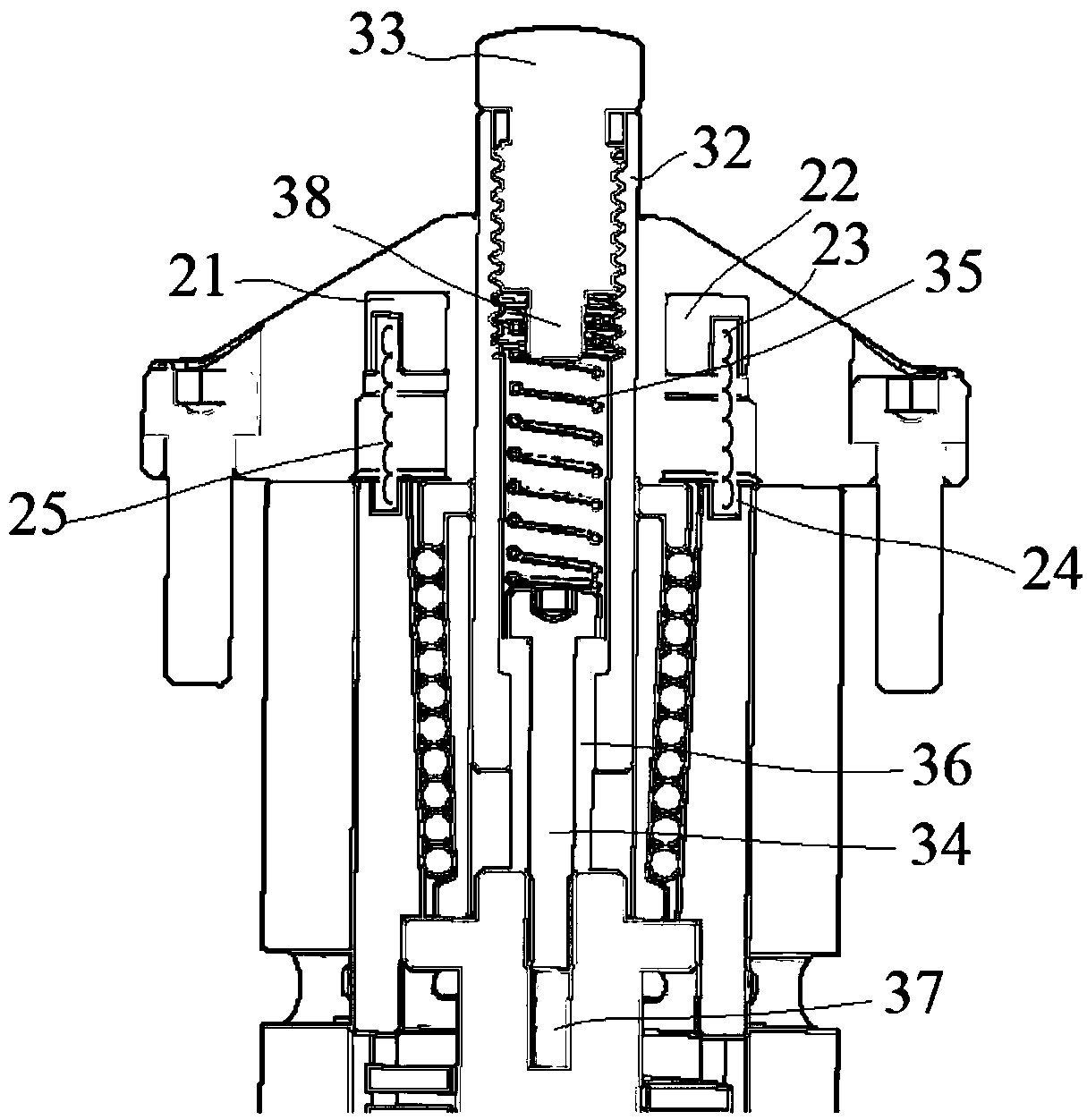

[0030]Embodiment 1: A kind of floating supporting device, comprises top cover 1, housing 2, bottom cover 3, push block 4, movable column 5 and support column 6, described top cover 1 and bottom cover 3 are connected with the shell 2 respectively The top surface and the bottom surface are tightly connected, so that a cavity 10 is formed between the top cover 1, the casing 2 and the bottom cover 3, and the lower end of the movable column 5 passes through the top cover 1 and extends into the cavity 10. The upper end of movable column 5 exposes top cover 1, and described support column 6 is arranged in cavity 10 and the lower end of support column 6 is fixedly connected with bottom cover 3, and described bottom cover 3 upper surface has a groove 12, and this groove The upper surface of 12 is provided with a plurality of through holes 13 for inserting the push block 4. The push block 4 includes a connecting portion 41 and a plurality of protrusions 42. The plurality of protrusions 4...

Embodiment 2

[0037] Embodiment 2: A kind of floating supporting device, comprises top cover 1, shell 2, bottom cover 3, push block 4, movable column 5 and support column 6, described top cover 1 and bottom cover 3 are connected with the shell 2 respectively The top surface and the bottom surface are tightly connected, so that a cavity 10 is formed between the top cover 1, the casing 2 and the bottom cover 3, and the lower end of the movable column 5 passes through the top cover 1 and extends into the cavity 10. The upper end of movable column 5 exposes top cover 1, and described support column 6 is arranged in cavity 10 and the lower end of support column 6 is fixedly connected with bottom cover 3, and described bottom cover 3 upper surface has a groove 12, and this groove The upper surface of 12 is provided with a plurality of through holes 13 for inserting the push block 4. The push block 4 includes a connecting portion 41 and a plurality of protrusions 42. The plurality of protrusions 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com