Method for controlling shutdown of auxiliary engine of clutchless hybrid electric vehicle brakes

A clutchless technology for hybrid vehicles, applied in hybrid vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of long engine shutdown time, unfavorable life of high-voltage accessories, and large loss of electrical appliances in the vehicle, so as to avoid excessive Load work, the method is simple and feasible, and the effect of high shutdown efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

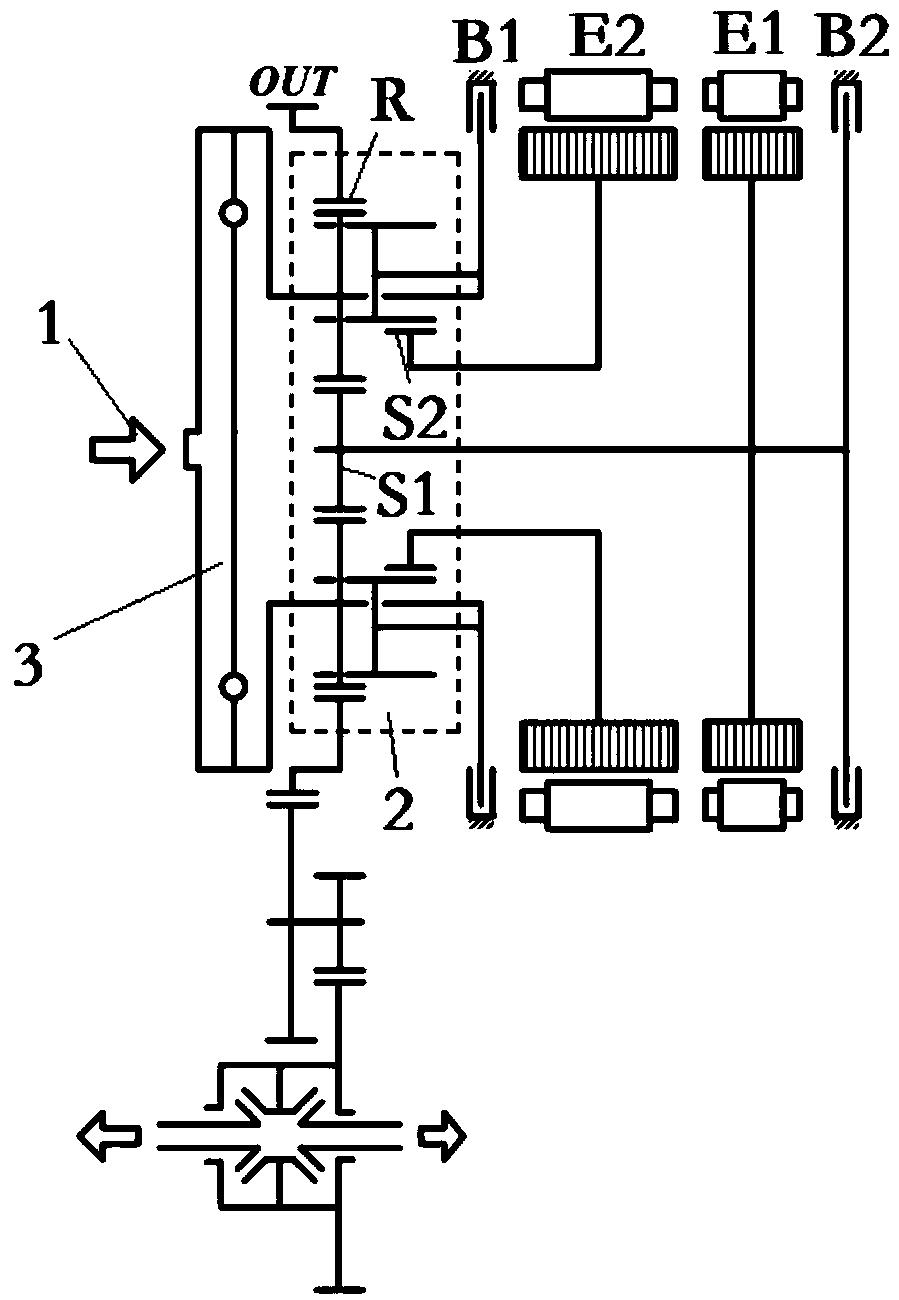

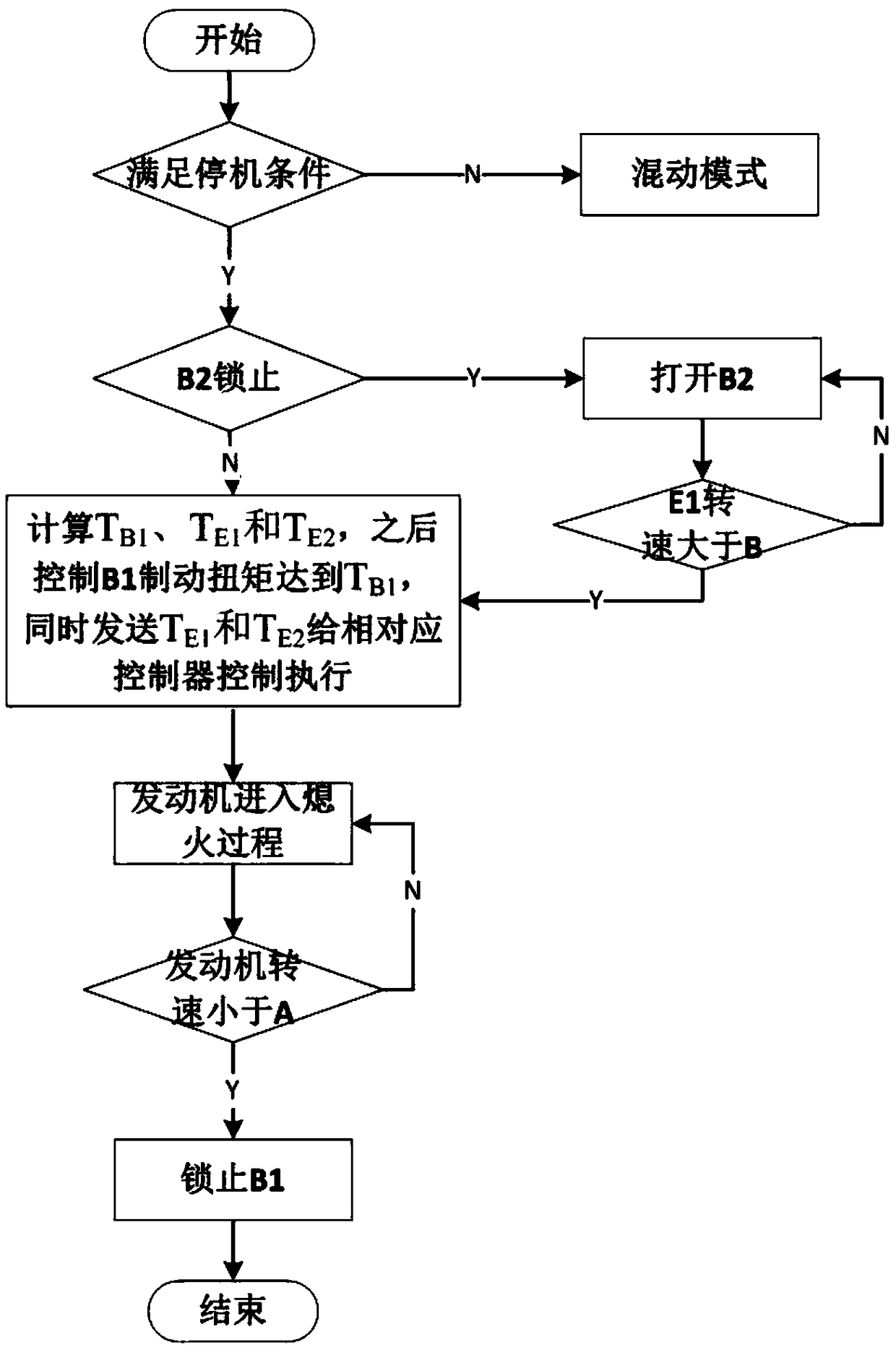

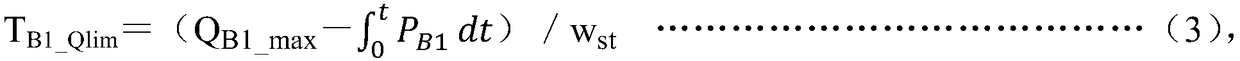

[0036]A control method for brake-assisted engine shutdown of a clutchless hybrid electric vehicle, performed according to the following steps:

[0037] Ⅰ The vehicle controller judges whether the vehicle meets the engine shutdown conditions. If the conditions are met at the same time (a) the engine water temperature is higher than the third preset value C, and the third preset value C is 45°C; (b) the vehicle is in the forward deceleration gear, (c) the vehicle speed is lower than 100km / h, (d) the continuous fuel cut command is established, then execute step II, otherwise the vehicle maintains the hybrid mode;

[0038] Ⅱ The vehicle controller judges whether the second brake B2 is locked. If so, the vehicle controller opens the second brake B2 by reducing the current of the solenoid valve. If the speed of the small motor E1 is greater than the second preset value B, the second preset value If B is 75rpm, it is judged that the second brake B2 is opened, and then execute step II...

Embodiment 2

[0057] A control method for brake-assisted engine shutdown of a clutchless hybrid electric vehicle, the steps of which are basically the same as the steps of the control method for brake-assisted engine shutdown of a clutchless hybrid electric vehicle in Embodiment 1, the difference being: in step I The third preset value C is 40°C, the second preset value B in step II is 50 rpm, and the first preset threshold A in step III is 30 rpm.

Embodiment 3

[0059] A control method for brake-assisted engine shutdown of a clutchless hybrid electric vehicle, the steps of which are basically the same as the steps of the control method for brake-assisted engine shutdown of a clutchless hybrid electric vehicle in Embodiment 1, the difference being: in step I The third preset value C is 50°C, the second preset value B in step II is 100 rpm, and the first preset threshold A in step III is 50 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com