Biological particle hot-blast stove

A technology of biological particles and hot blast stoves, applied in fluid heaters, lighting and heating equipment, etc., can solve the problems of pipeline tempering, fuel type restrictions, size requirements, etc., to reduce heat waste and facilitate cleaning and maintenance , easy replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

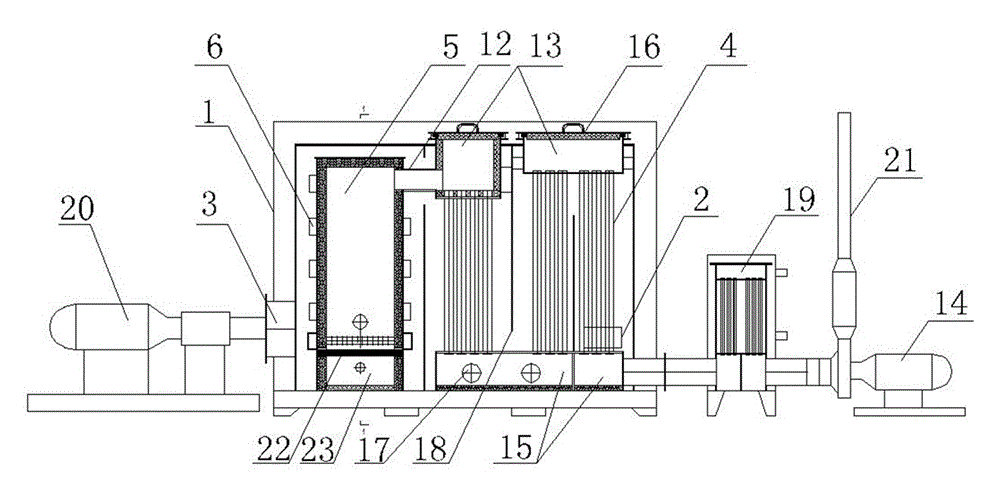

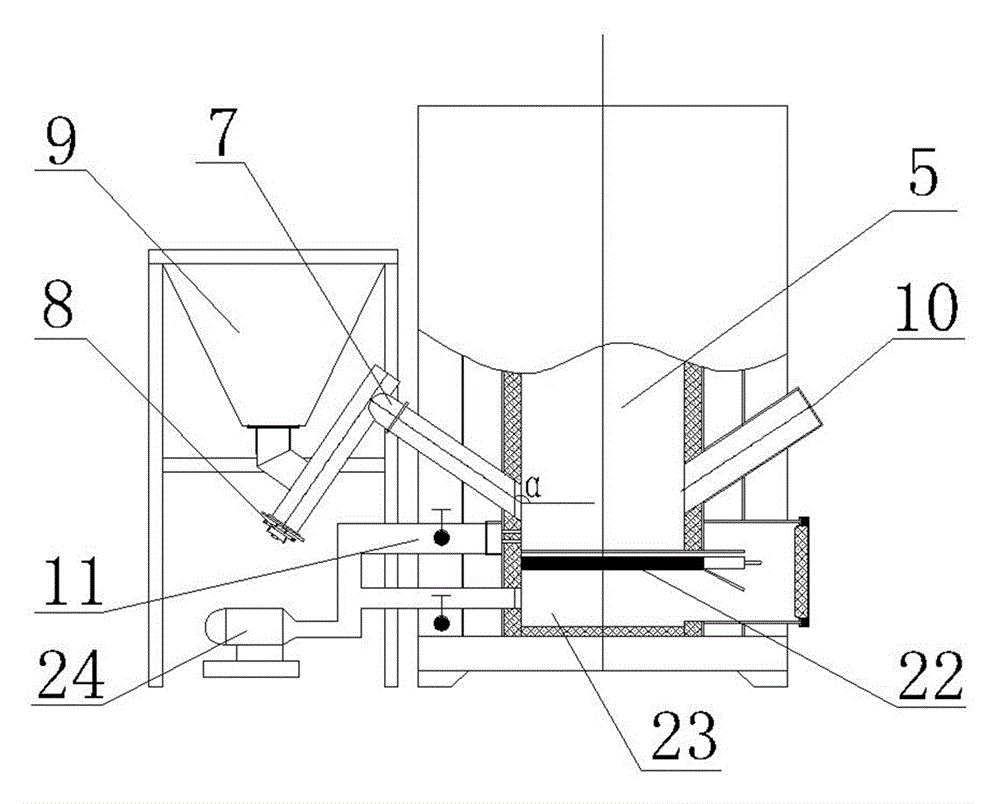

[0018] The present invention will be further described in detail below in conjunction with the drawings.

[0019] See figure 1 with figure 2 As shown, a biological particle hot air stove includes a furnace body 1. Both sides of the furnace body 1 are provided with a cold air inlet 2 and a hot air outlet 3 respectively. The hot air outlet 3 is connected to a circulating fan 20, and the cold air inlet 2 is provided with an air filter device. The air to be heat exchanged is drawn in for dust removal and filtration to reduce the dust carried by the air from adhering to the wall of the heat exchange pipe 4, which affects the heat exchange effect; the furnace body 1 is provided with a furnace 5, and the outer periphery of the furnace 5 is provided with a number of heat exchange fins The fins 6 and the heat exchange fins 6 increase the heat exchange area; the furnace 5 is provided with a feeding tube 7 obliquely on one side, and the angle α between the center line of the feeding tube 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com