sewing machine

A sewing machine and groove technology, which is applied in the field of sewing machines, can solve the problems that the hook tip cannot catch the upper thread, the upper thread is slack without sufficient margin, residue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0121] (The overall configuration of the sewing machine)

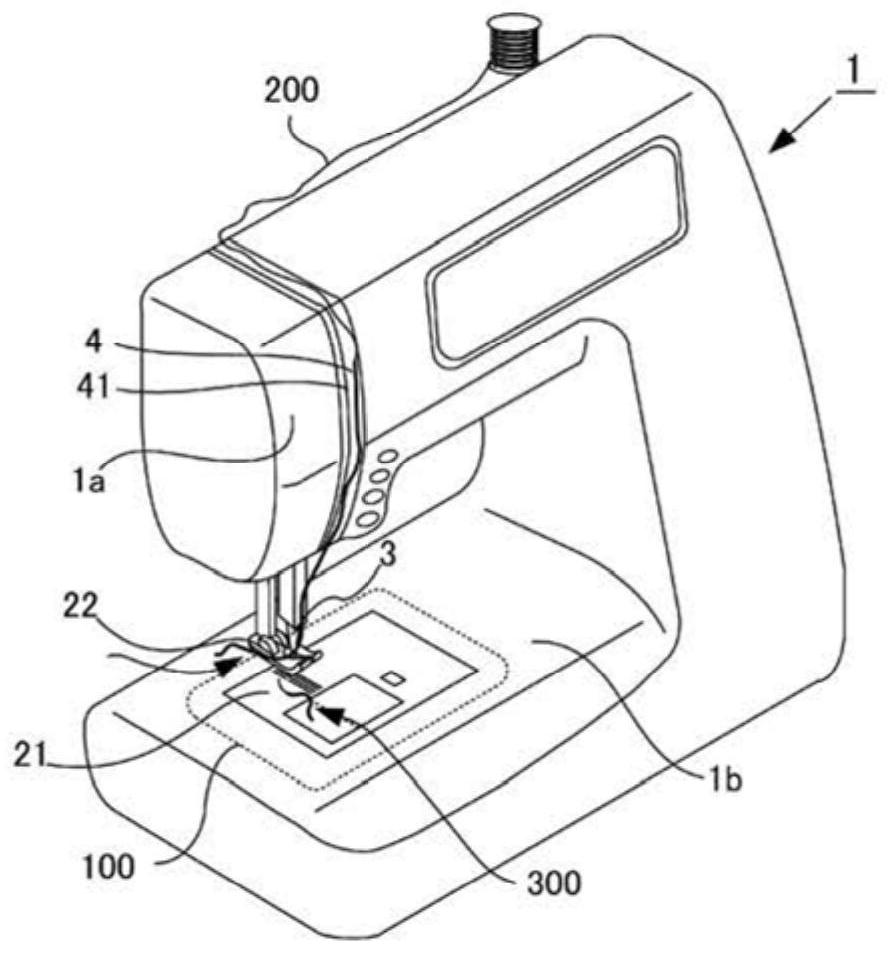

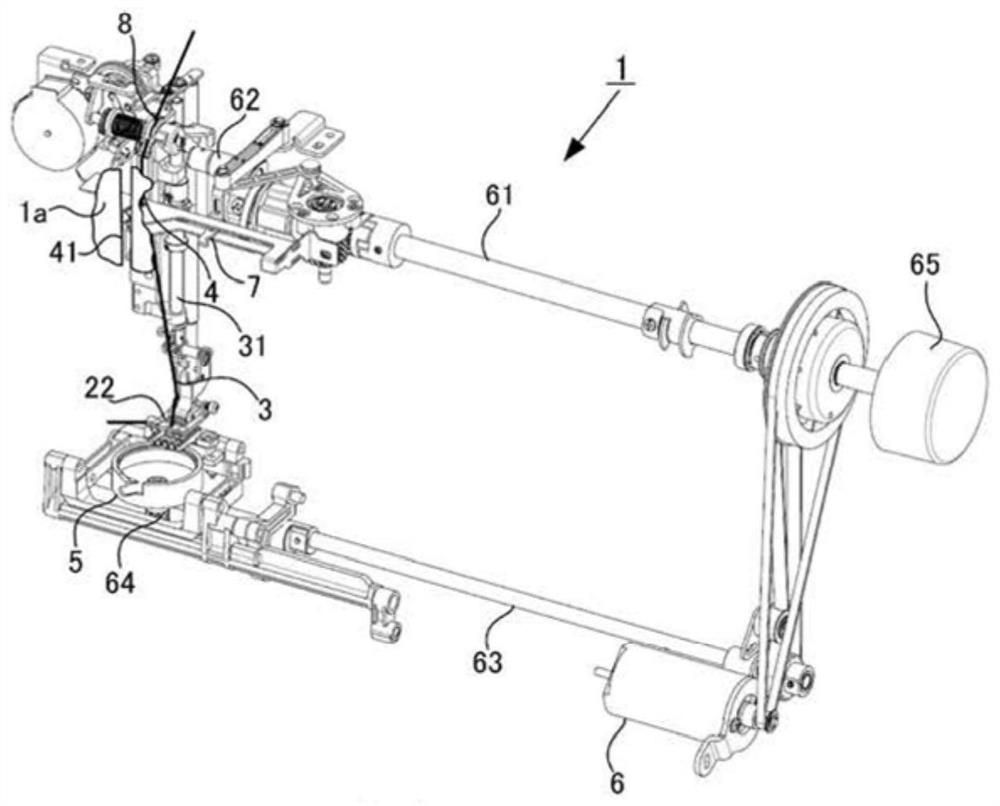

[0122] A sewing machine according to a first embodiment will be described in detail with reference to the drawings. The sewing machine 1 shown in Fig. 1(a) and Fig. 1(b) is a household, special-purpose or industrial device for sewing cloth 100. The needle 3 is dropped on the cloth 100 placed on the needle plate 21 to make the cloth 100 sew. The upper thread 200 interweaves with the lower thread 300 to form a stitch. The sewing machine 1 includes: a needle bar 31 that supports the needle 3 at its tip and reciprocates together with the needle 3; and a shuttle 5 that has a tip on the outer periphery and rotates together with the tip.

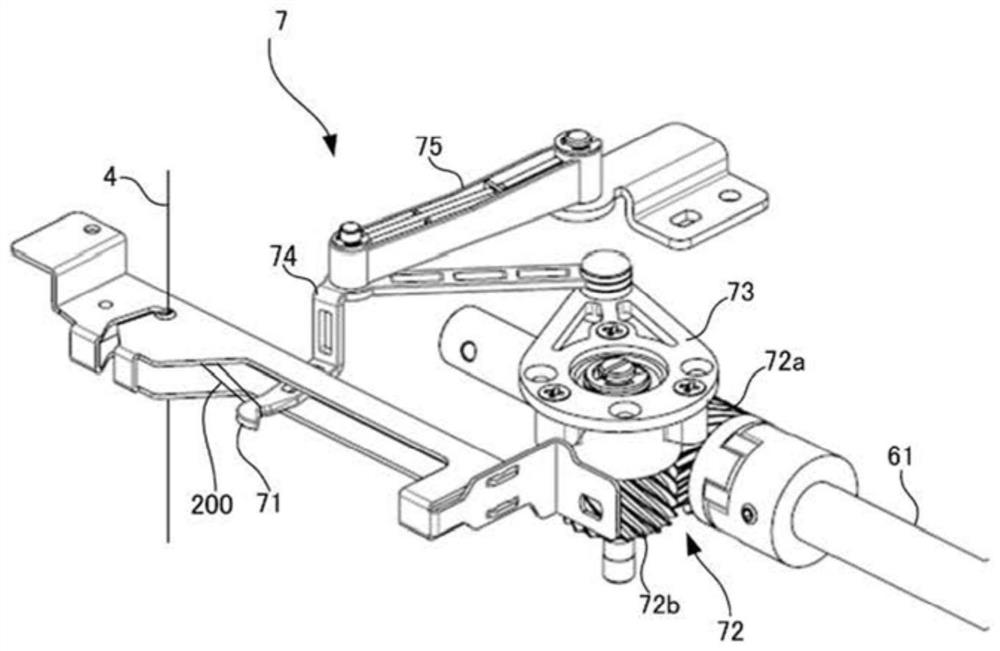

[0123] The needle bar 31 extends vertically from the machine head 1 a of the sewing machine 1 toward the needle plate 21 , and supports the needle 3 at the front end on the needle plate 21 side. The user pulls out the upper thread 200 from the winding shaft, hangs it into the groove 41 fo...

no. 2 Embodiment approach

[0178] A sewing machine 1 according to a second embodiment will be described in detail with reference to the drawings. The same symbols are assigned to the same configurations and functions as those of the first embodiment, and detailed description thereof will be omitted.

[0179] As shown in FIG. 13( a ) and FIG. 13( b ), the presser foot 22 of the sewing machine 1 can move up and down in the direction of contacting and separating from the cloth 100 . As the presser foot 22 rises, the cloth 100 and upper thread 200 sandwiched between the needle plate 21 and the presser foot 22 are released. Therefore, while the presser foot 22 is raised, the cloth 100 and the upper thread 200 can be exchanged.

[0180] Such a presser foot 22 is detachably mounted on the front end of the press bar 221 . The sole of the presser foot 22 faces the needle plate 21 through the cloth 100 . The pressing rod 221 is arranged on the sewing machine frame, extends vertically toward the needle plate 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com