an integrated sensor

An integrated sensor and sensing technology, applied in the field of integrated sensors, can solve problems such as poor contact of each node, achieve the effect of reducing off-line problems, reasonable structure, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

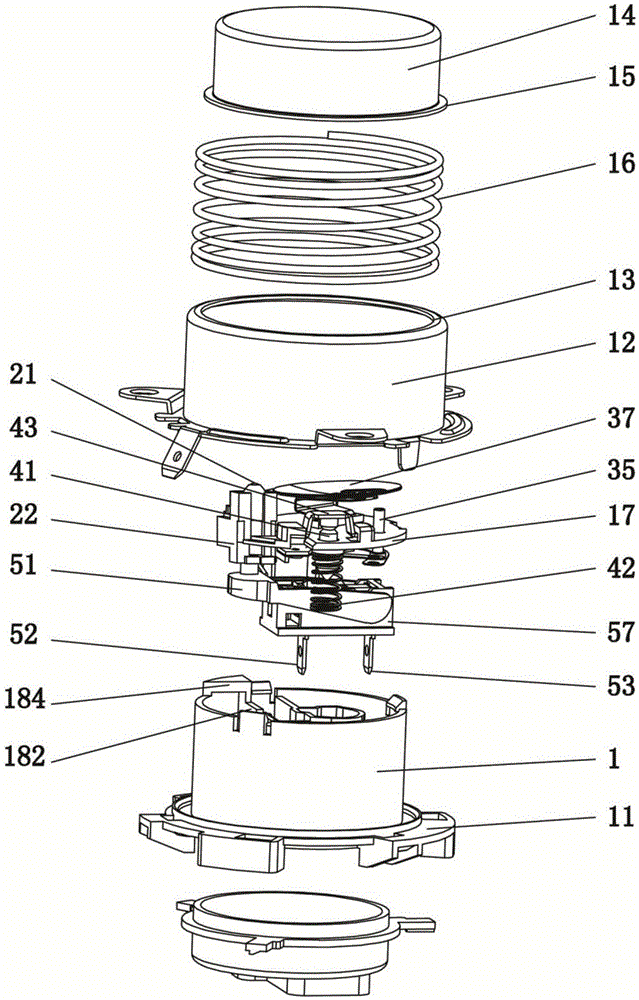

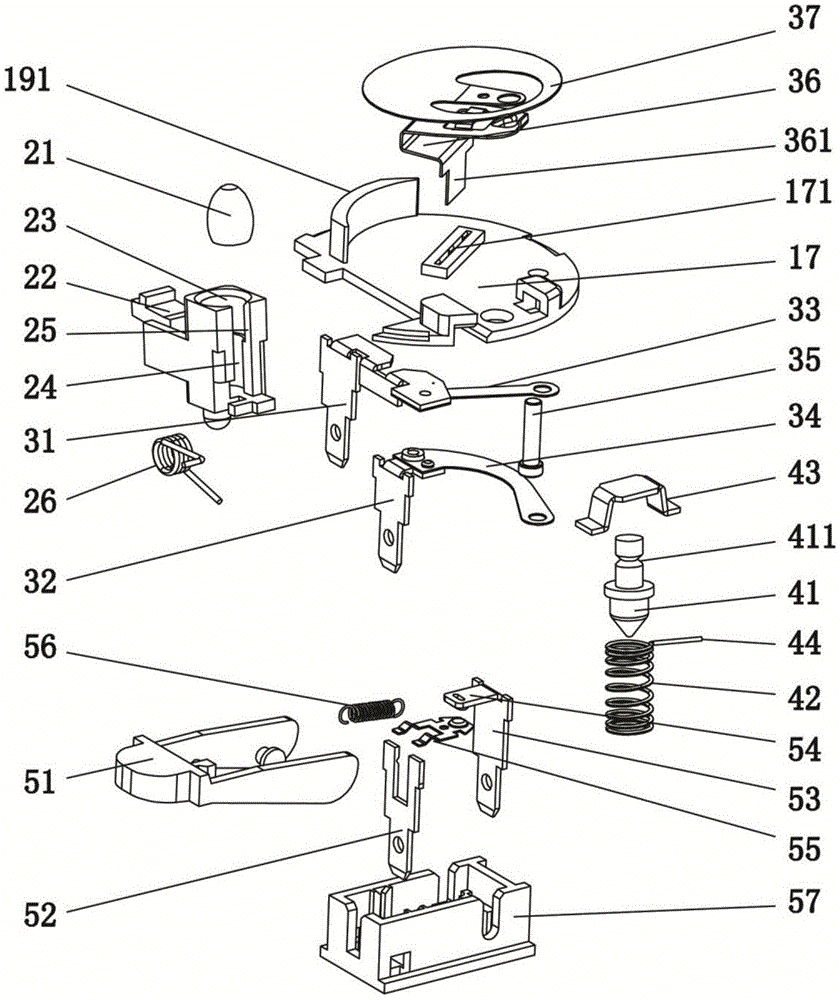

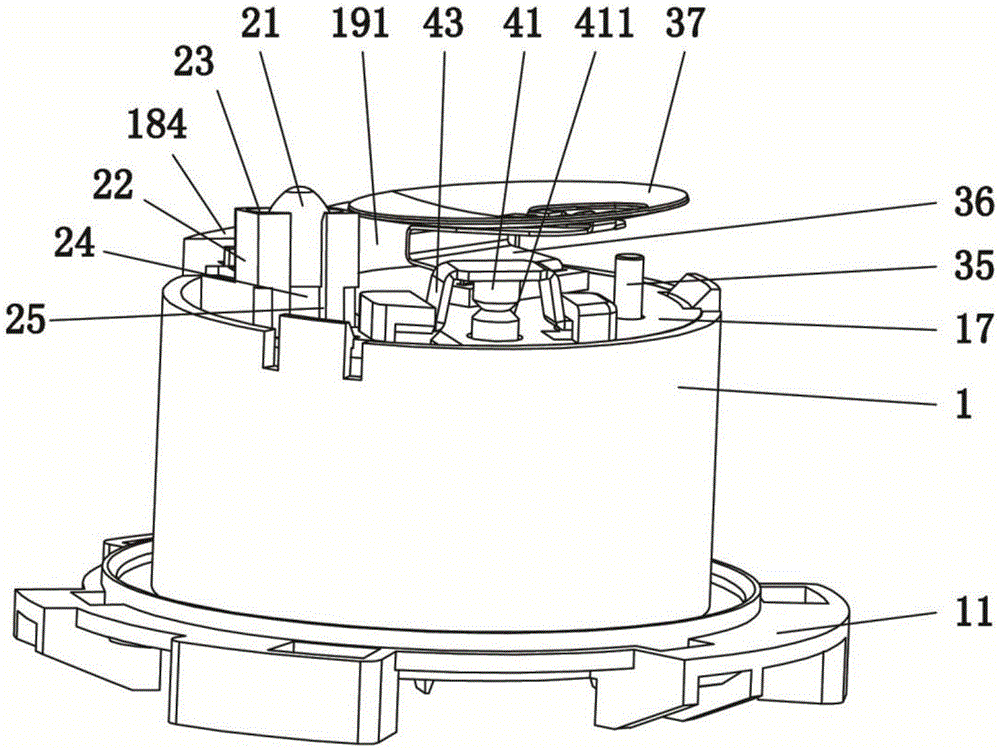

[0054] The present invention will be further described below in conjunction with the accompanying drawings.

[0055] Such as Figure 1-6As shown, an integrated sensor according to the present invention includes a base 1, the base 1 is provided with sensing components, the upper end of the base 1 is provided with an upper cover 14 that moves independently relative to it, and the base 1 and the upper cover 14 A compression spring 16 is provided between them; the upper cover 14 interferes with the sensing components in the base 1 during the downward stroke; as Figure 5 As shown, the base 1 is fixedly installed in the electric heating vessel 61 and the sensing part is electrically connected to the main control board of the electric heating vessel 61. The upper cover 14 can be moved up and down on the heating tray 63, and the upper cover 14 is connected to the base in the initial state. The sensing parts in 1 are relatively non-contact. The inner pot 62 is put into the electric h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com