Vertical shaft protective sleeve

A technology for protecting casing and casing, which is used in wellbore/well components, earthwork drilling, building locks, etc. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

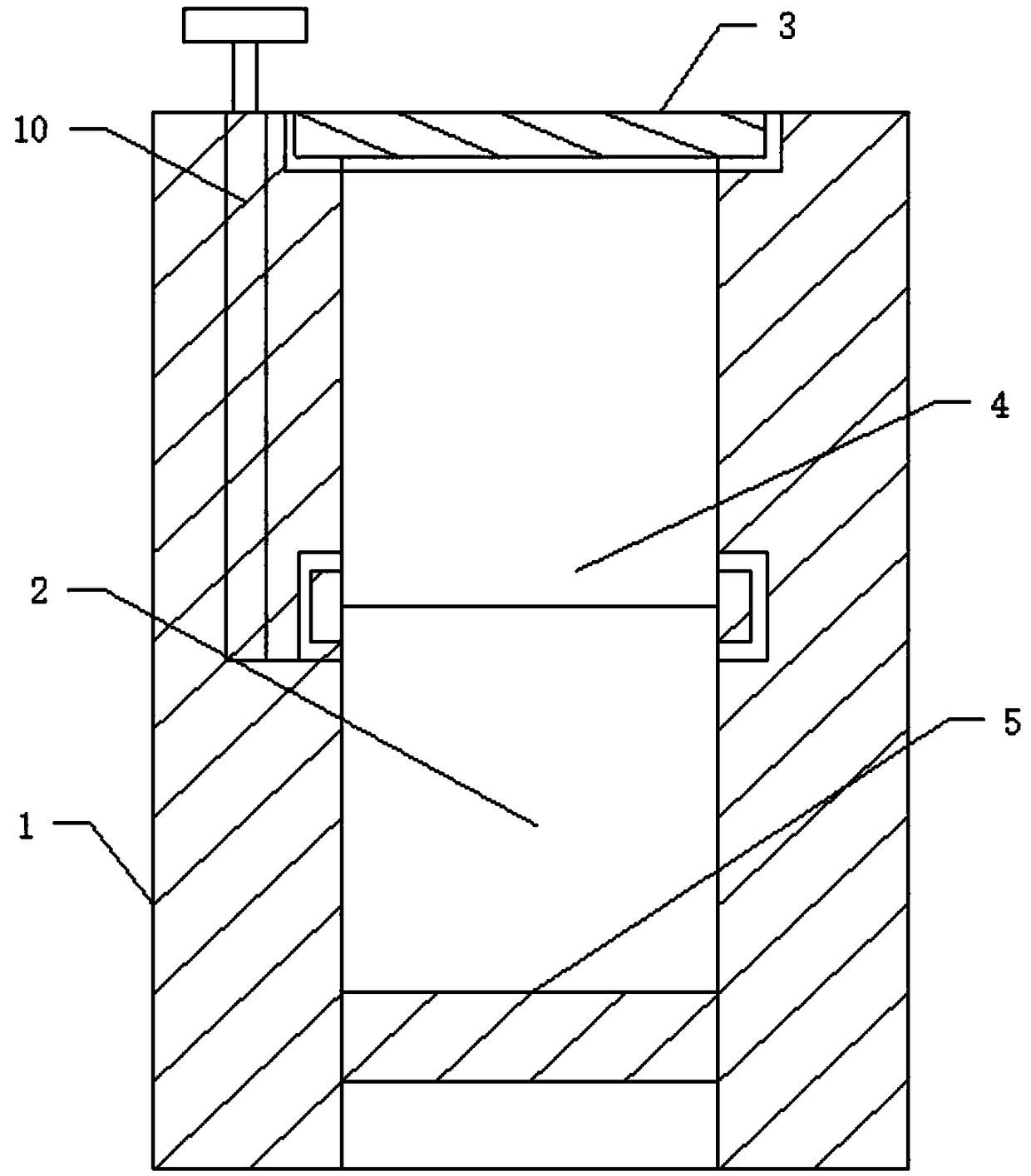

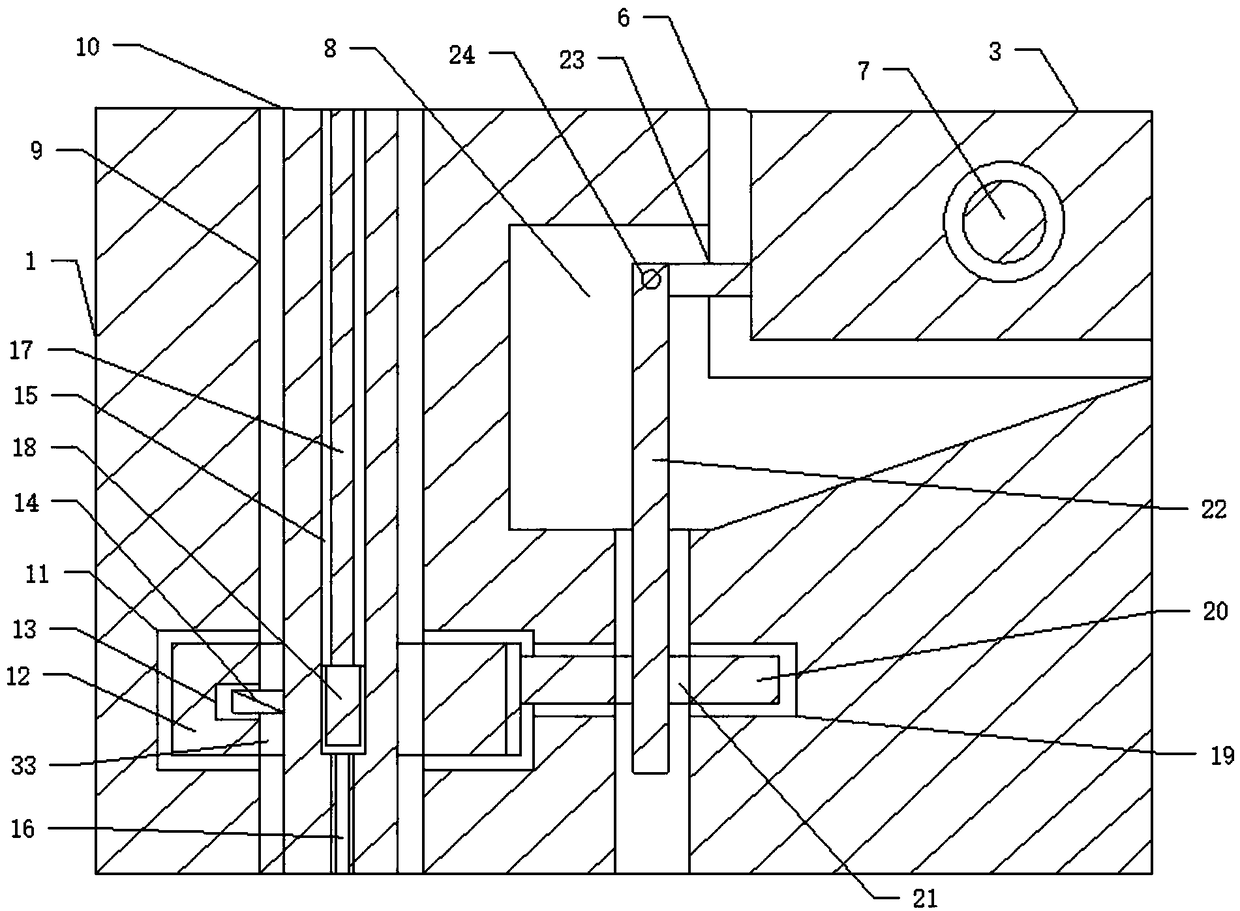

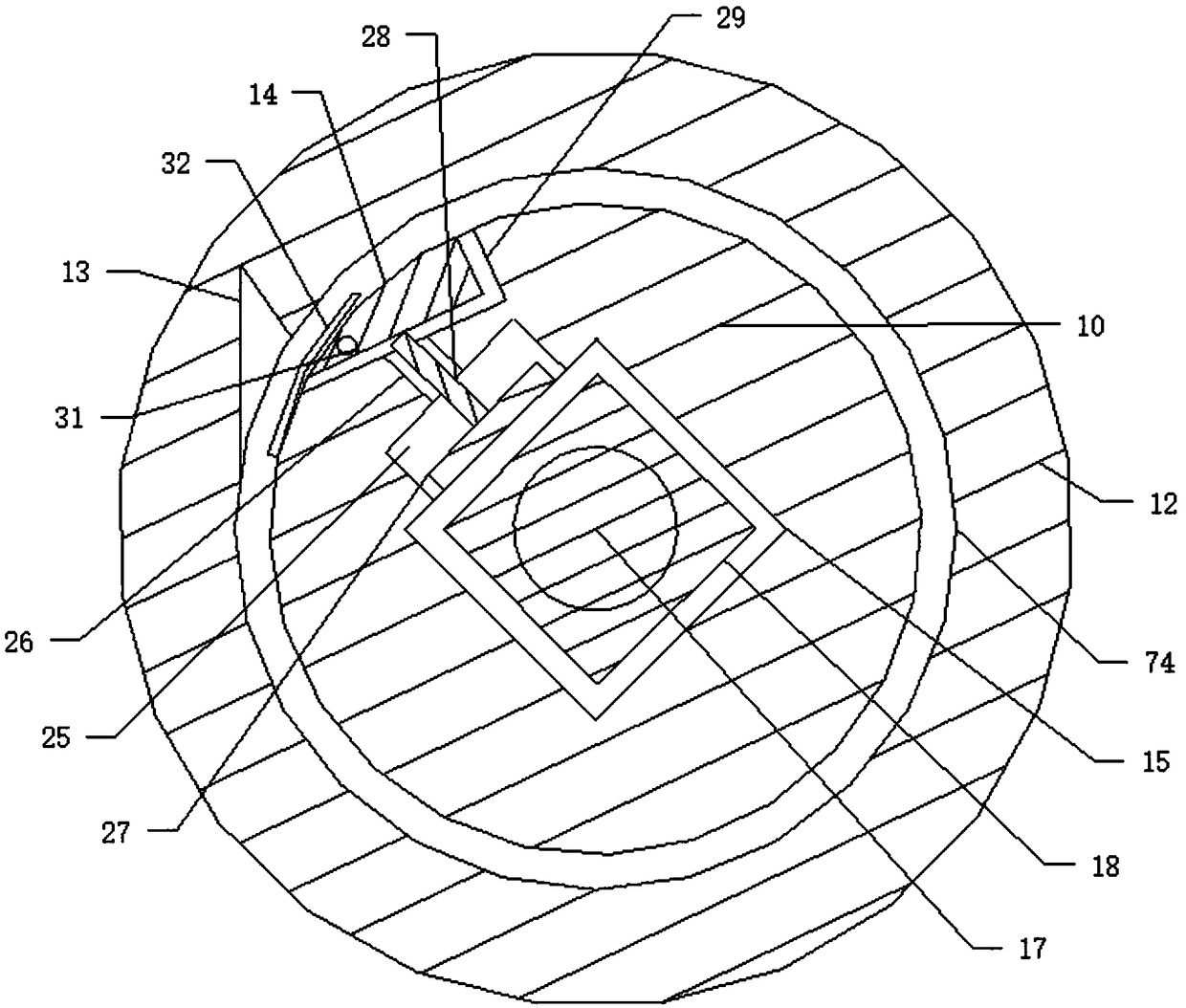

[0028] Such as Figure 1 to Figure 6 As shown, a shaft protective sleeve includes a safety sleeve 1, a pipe inner groove 2 is arranged in the safety sleeve 1, a rotating control shaft 10 is arranged in the safety sleeve 1, and the safety sleeve 1 There is also a rotating first gear 12 inside, the control shaft 10 drives the first gear 12 to rotate, the control shaft 10 is provided with a second rotating hole 15, and the second rotating hole 15 is provided with There is a sliding first control rod 17, and a control end 18 is arranged on the first control rod 17, and the control end 18 controls the connection between the control shaft 10 and the first gear 12, the A rotating protective outer cover 3 is arranged on the safety sleeve 1 , and the rotation of the first gear 12 controls the opening and closing of the protective outer cover 3 .

[0029] The safety sleeve 1 can be set in the shaft position and can be buried in the ground. An inner groove 2 is arranged on the safety sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com