A method for detecting the appearance of each coating of a paint composite coating

A composite coating and detection method technology, applied in the detection of the appearance of each coating of the coating composite coating, evaluating the coating in the wet-on-wet application process, evaluating the appearance of each coating in the wet-on-wet process of the coating, in the field of detection, can be Solve problems such as inability to accurately evaluate the appearance of composite coatings, and achieve the effect of improving appearance and accurate evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The solvent-based black paint is painted by 3C2B painting process, and the appearance is improved after painting.

[0030] According to the production site data, in the process of using SP M-180BG41 black color paint (solvent-based) coating, the paint film appearance is worse than the previous batch, and detects according to the detection method of each coating appearance of the coating composite coating of the present invention:

[0031] 1. Use the previous batch of black paint samples for board making and testing:

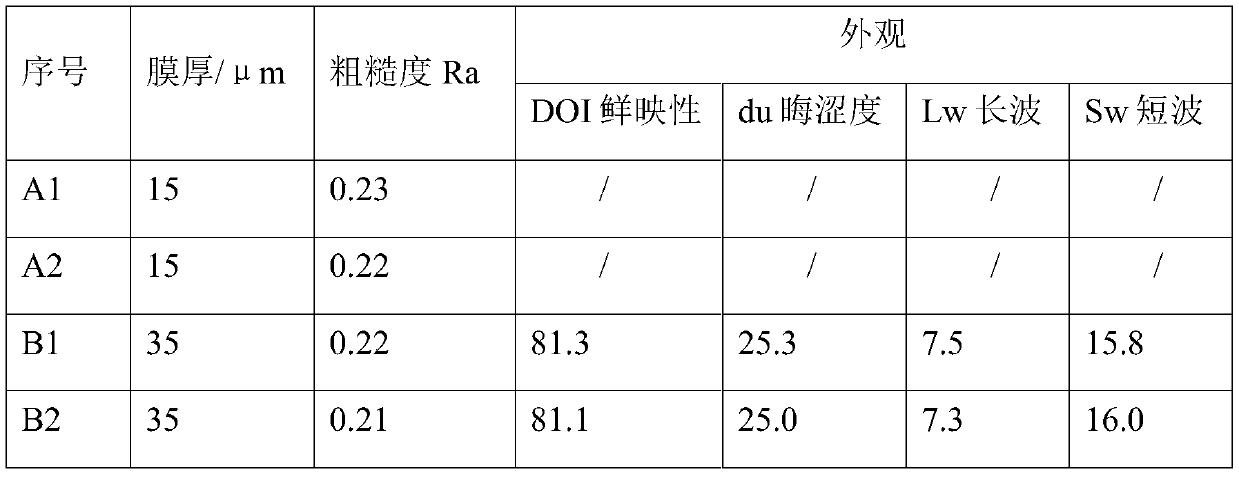

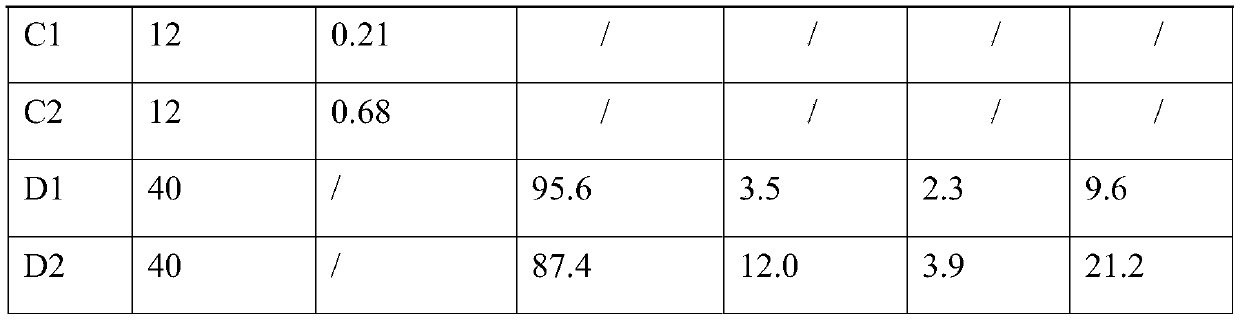

[0032] Step 1: Substrate treatment: Wipe multiple electrophoresis plates clean with degreasing solvent or alcohol, and paste film thickness strips, one of which is recorded as A1 plate or the first bottom plate, and use a roughness meter to test the A1 plate or the first bottom plate The roughness Ra is measured, and the film thickness of the A1 plate or the first base plate is measured using a film thickness meter (data are shown in Table 1);

[0033]Ste...

Embodiment 2

[0053] When evaluating the appearance of a water-based 3C1B coating, when the overall appearance deteriorates, it is extremely important to find the cause of the deterioration. For the coating constructed by the 3C1B process, the appearance data measured by the orange peel meter is the appearance of the entire composite coating data.

[0054] Detect according to the detection method of each coating appearance of the coating composite coating of the present invention:

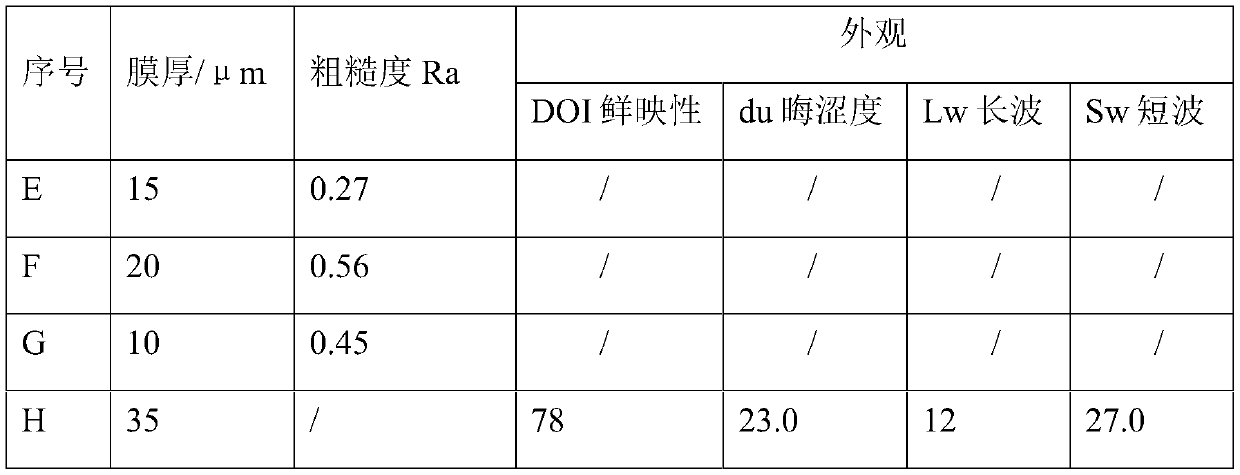

[0055] Step 1: Substrate treatment: Wipe the electrophoresis plate clean with degreasing solvent or alcohol, and attach a film thickness strip; use the electrophoresis plate as E plate (the first bottom plate), and measure the roughness Ra and film thickness of the E plate (data as shown in Table 2);

[0056] Step 2: Spray three pieces of AR-620 8105 primer on the E electrophoresis plate, flash dry for 7 minutes, and bake at 80°C for 5 minutes, take out the primer plate E, take one piece of primer and put it in...

Embodiment 3

[0067] Appearance evaluation of waterborne 3C1B topcoat layer composed of two paints:

[0068] When evaluating the appearance of a water-based 3C1B coating, the appearance data measured by the orange peel meter is the appearance data of the entire composite coating. When analyzing the appearance of the paint film, due to the special color of pearlescent white, the entire paint film is composed of five coatings: electrophoretic layer, middle coat, primer, pearlescent paint, and varnish. There are many coatings that affect the overall appearance of the paint film. Traditional appearance measurement methods cannot determine the effect of a specific coating on appearance.

[0069] Detect according to the detection method of each coating appearance of the coating composite coating of the present invention:

[0070] Step 1: Substrate treatment: Wipe the electrophoresis plate clean with degreasing solvent or alcohol, and paste the film thickness strip; use the electrophoresis plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com