Greenhouse ridger

A technology for ridging machines and greenhouses, which is applied in the fields of land preparation machinery, agricultural machinery and implements, etc. It can solve the problems of heavy labor, low work efficiency, and low quality of ridges, and achieve increased space, meeting planting needs, and convenient The effect of walking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

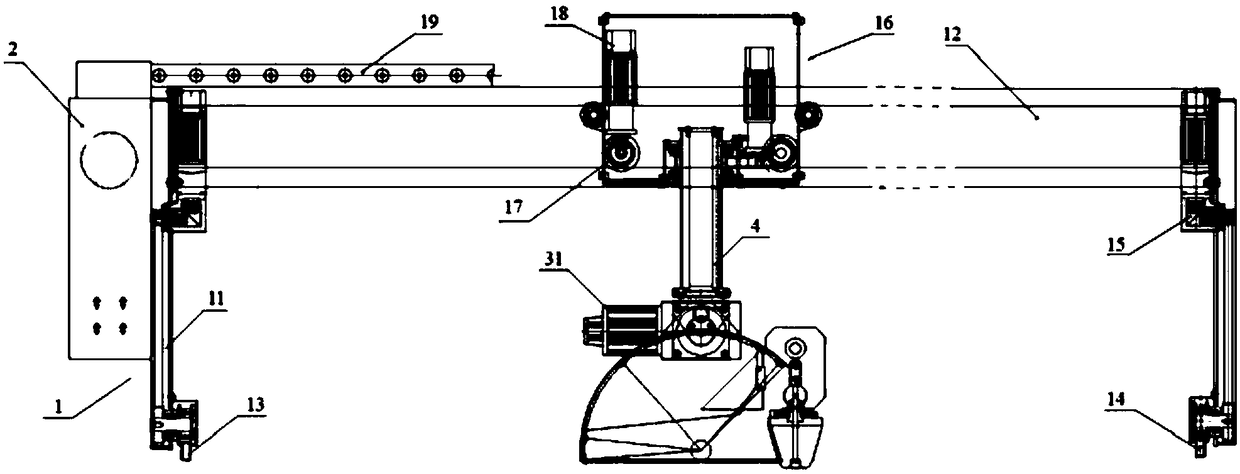

[0022] to combine figure 1 , the present embodiment provides a greenhouse ridging machine, comprising a first guide rail and a second guide rail arranged in parallel and a door-shaped traverse frame 1 straddling the first guide rail and the second guide rail, the door-shaped traverse frame 1 The bottom of the support frame 11 of the moving frame is provided with a first moving mechanism for moving along the first and second guide rails, and the beam frame 12 of the door-shaped traverse frame is provided with a second moving mechanism for moving along the beam frame.

[0023] Specifically, the first moving mechanism includes a first moving wheel 13 that is arranged on the bottom of the support frame 11 and is compatible with the first guide rail and a second moving wheel 14 that is compatible with the second guide rail, and the support frame is also provided with A drive motor 15 that drives the first moving wheel and the second moving wheel to rotate synchronously. Wherein, t...

Embodiment 2

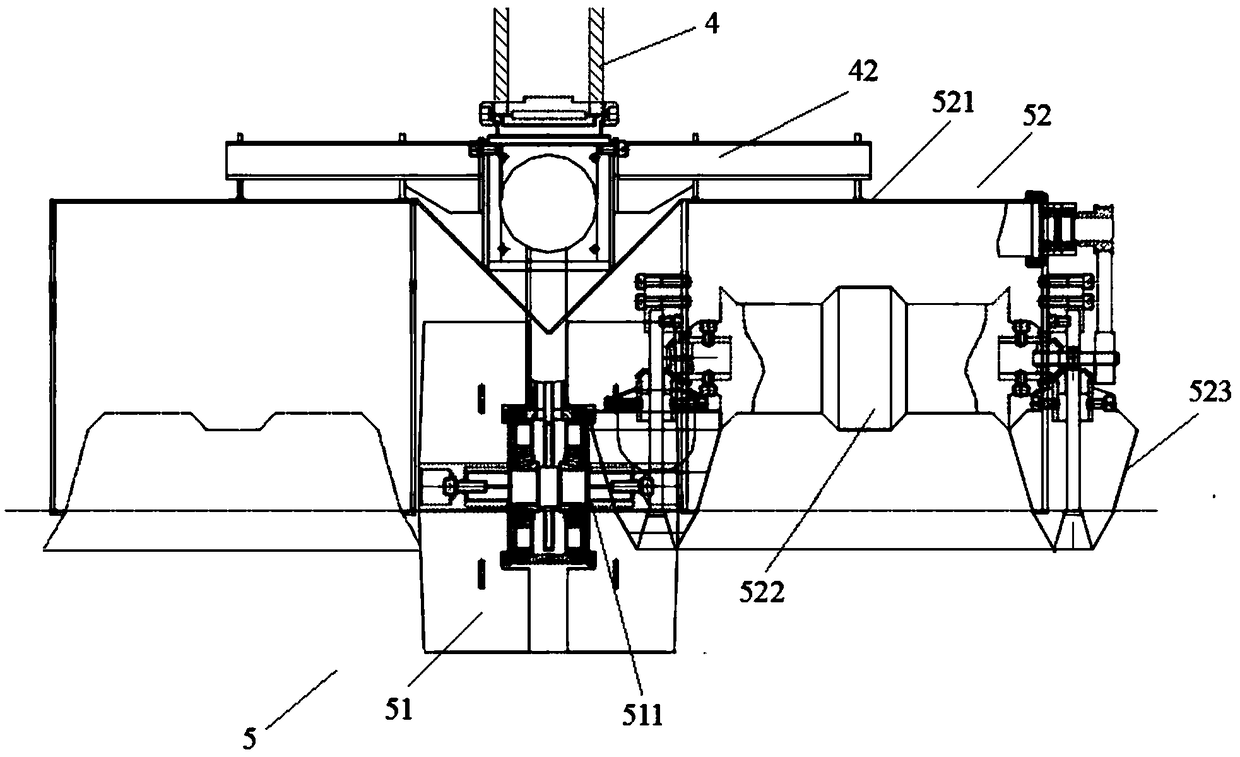

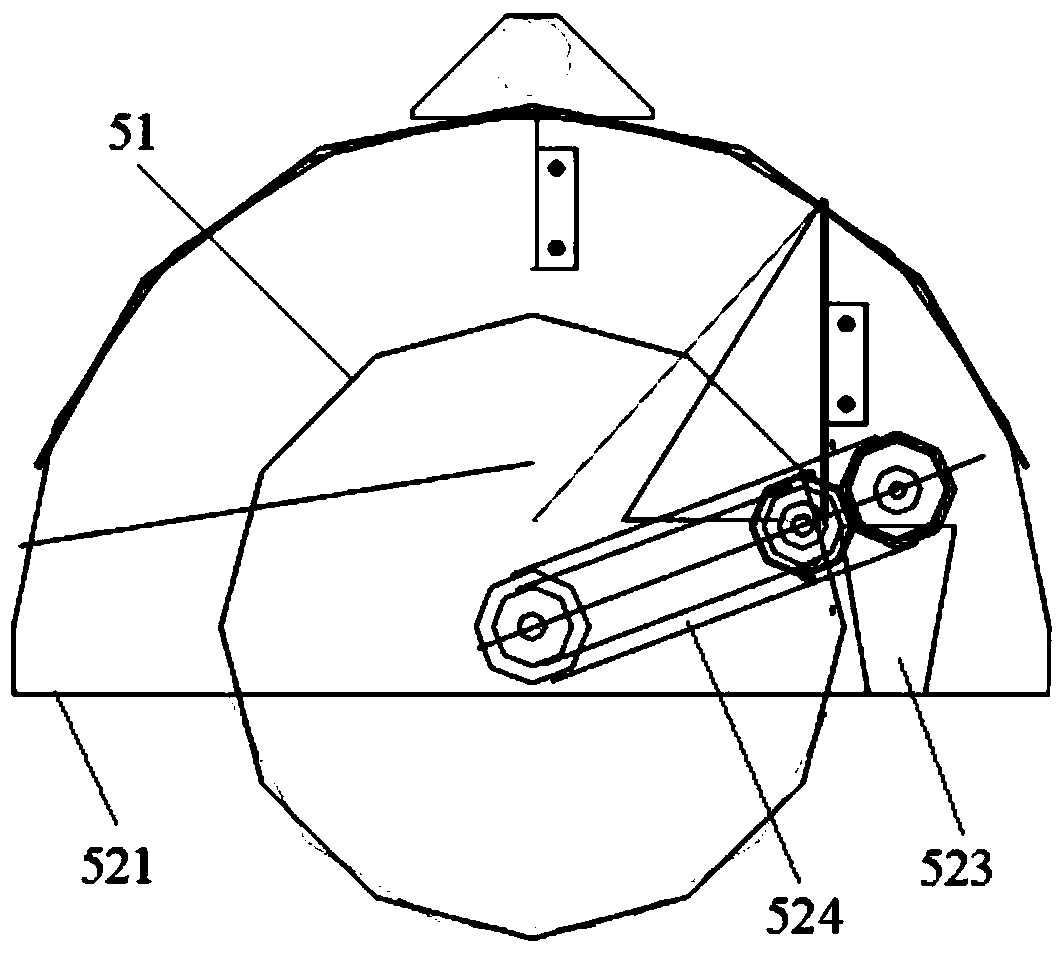

[0028] to combine figure 2 , image 3 and Figure 4 , as a specific solution of Embodiment 1, in this embodiment, the shaping mechanism 52 includes a ridging cover 521, a pressure roller 522 arranged in the ridging cover along the horizontal direction, and a shaping wheel 523 arranged on the side wall of the ridging cover;

[0029] The pressure roller 522 is rotatably connected with the side wall of the ridge cover along the direction perpendicular to the ridge, and the pressure roller is located in front of the rotating head along its moving direction;

[0030] The shaping wheel 523 is conical, the upper diameter is greater than the lower diameter, the conical wheel is rotationally connected to the side of the ridging cover, and the rotating shaft of the shaping wheel corresponds to the rotating shaft of the pressing roller. It is connected by bevel gear transmission; the side wall of the ridging cover is provided with a driving mechanism for driving the pressure roller an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com