Device and method for recovering nitric acid from waste liquid containing nitric acid

A recovery device, nitric acid technology, applied in the field of uranium hydrometallurgy, can solve the problems of high cost, unfavorable production, environmental pollution, low recovery rate of nitric acid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

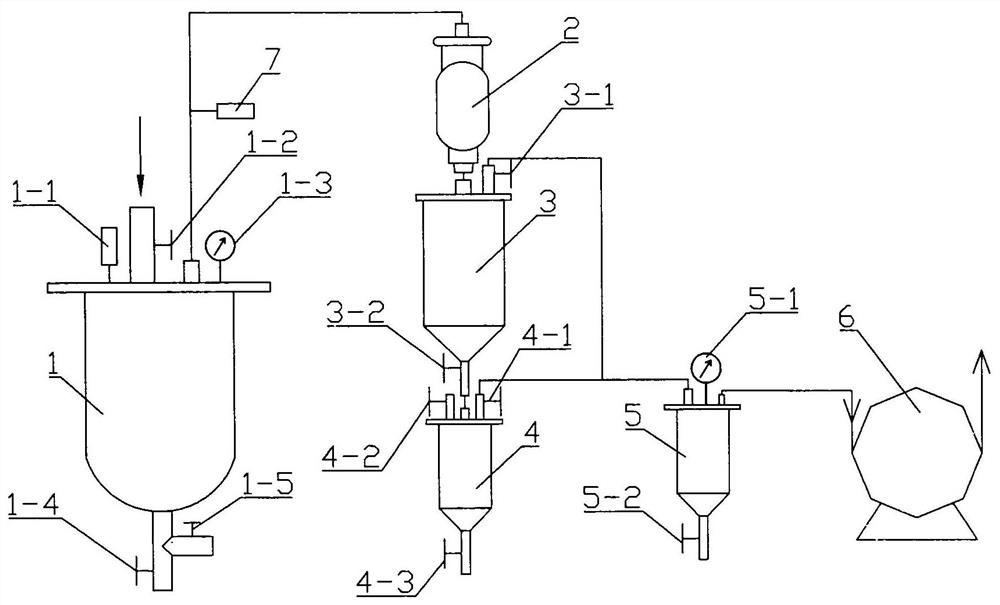

[0061] Embodiment 1. The device for recovering nitric acid from waste liquid containing nitric acid, including a distillation kettle 1 with a heating and stirring device, a condenser 2, a distillation buffer tank 3, a liquid storage tank 4, and a second vacuum gauge 5-1 Buffer tank 5, vacuum pump 6.

[0062] The top of the still 1 is provided with a first thermometer 1-1 for measuring the temperature of the liquid in the still 1, a first valve 1-2 is provided at the feed port, and a first vacuum for measuring the vacuum degree of the still 1 is provided at the top. Table 1-3, the bottom three-way discharge pipe is provided with a second valve 1-4 and a third valve 1-5, and the third valve 1-5 is used for sampling.

[0063] A fourth valve 3-1 is provided on the air outlet pipe at the top of the distillation buffer tank 3, and a fifth valve 3-2 is provided on the outlet pipe at the bottom of the distillation buffer tank 3.

[0064] A sixth valve 4-1 is provided on the air outle...

Embodiment 2

[0067] Embodiment two, adopt the recovery device as described in embodiment one to reclaim the method for nitric acid from waste liquid containing nitric acid, the content of nitric acid in the waste liquid containing nitric acid is 100~250g / L, and the whole recovery process adopts intermittent two-stage Distillation, the secondary distillation is carried out after the primary distillation, and the primary distillation and the secondary distillation are completed by a recovery device.

[0068] The specific operation steps are as follows:

[0069] A. Primary distillation

[0070] A1. Open the first valve 1-2 on the feed port of distillation still 1 to add waste liquid containing nitric acid. The amount of waste liquid containing nitric acid is two-thirds to four-fifths of the volume of still kettle 1. Close the first valve after feeding is completed. A valve 1-2, simultaneously open the fourth valve 3-1 on the air outlet pipeline of the distillation buffer tank 3, the fifth va...

Embodiment 3

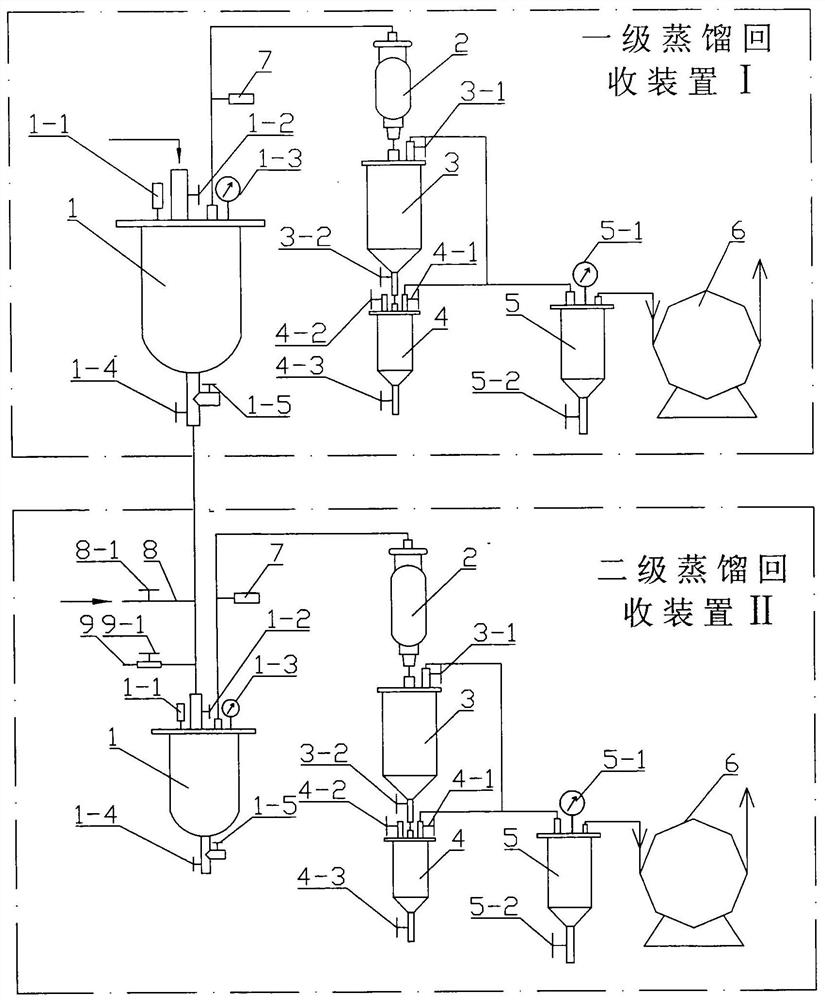

[0086] Embodiment three, from the two-stage series connection device that reclaims nitric acid from nitric acid waste liquid, two sets of recovery devices as described in embodiment one are connected in series, and in two sets of recovery devices connected in series, one set of recovery devices is used as a Stage distillation recovery device I is used for primary distillation, and a set of recovery device is used as secondary distillation recovery device II for secondary distillation.

[0087] Wherein: the volume of the still kettle 1 in the secondary distillation recovery device II is half of the volume of the still kettle 1 in the primary distillation recovery device I.

[0088] The volume of the distillation buffer tank 3 in the secondary distillation recovery device II is half of the volume of the distillation buffer tank 3 in the primary distillation recovery device I.

[0089] The volume of the liquid storage tank 4 in the secondary distillation recovery device II is hal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com