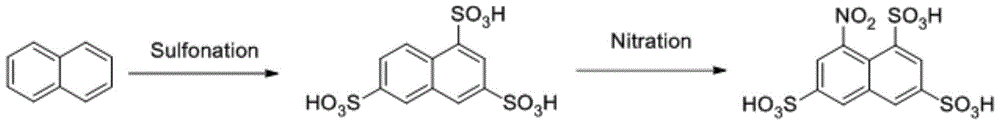

A method for resource utilization of residual nitric acid in the nitration solution of H acid

A technology of nitrification and resource utilization, applied in the preparation of sulfonic acid, organic chemistry, etc., can solve the problems of hidden safety and environmental protection, difficult equipment selection, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

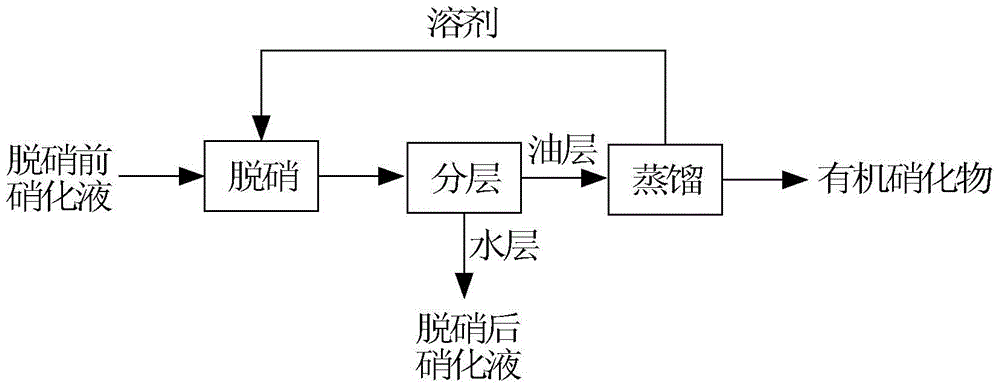

Method used

Image

Examples

Embodiment 1

[0025] Add 47.21g of toluene into a 250mL four-neck flask, stir well, and raise the temperature to 40°C. 123.37g of nitrification solution before denitrification, DVS value of 6.10, and nitric acid content of 2.62%, was added dropwise to a four-neck flask, reacted at 40°C for 1 hour, and then left to separate layers. The obtained water layer was 120.26g, with a nitric acid content of 65ppm. The oil layer is 43.32g, the yield of o-nitrotoluene is 63.38%, and the yield of p-nitrotoluene is 36.62%.

Embodiment 2-4

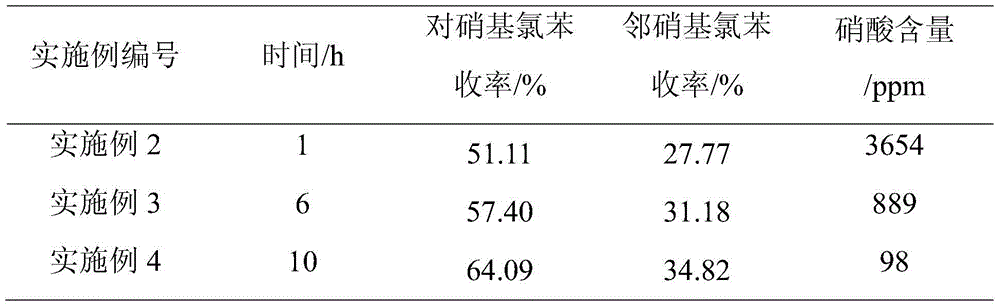

[0027] On the basis of Example 1, 57.76 g of chlorobenzene was used instead of toluene as the solvent, and other conditions remained unchanged. The obtained results are shown in Table 1.

[0028] Table 1 Chlorobenzene is used as a solvent, and the influence of different reaction times on denitrification

[0029]

Embodiment 5

[0031] Add 40.08g of benzene into a 250mL four-necked flask, stir well, and raise the temperature to 40°C. 123.37g of nitrification solution before denitrification, DVS value of 6.10, and nitric acid content of 2.62%, was added dropwise to a four-neck flask, reacted at 40°C for 1 hour, and then left to separate layers. The obtained water layer was 120.32g, with a nitric acid content of 83ppm. The oil layer is 43.07g, and the yield of nitrobenzene is 99.86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com