Ferrule quality detection device

A detection device and ferrule technology, which is applied in the direction of measuring devices, workpiece clamping devices, instruments, etc., to achieve the effects of accelerating roll-out speed, improving detection efficiency and quality, and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

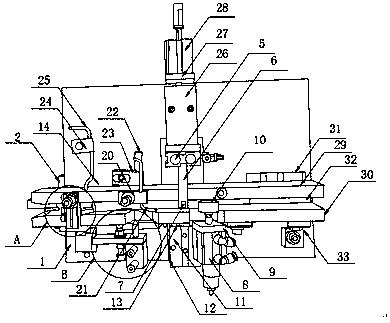

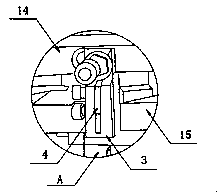

[0027] according to Figure 1-4 A ferrule quality detection device shown includes a bottom plate 1, a material path and a raceway, and is characterized in that: the material path and the raceway are both arranged on the side of the bottom plate 1, and the raceway is arranged on the side of the material path , and the material channel and the raceway are collinearly arranged on the same horizontal plane, the material channel connector 2 is arranged on one side of the material channel, and the clamping plate fixed connection seat 3 is fixedly provided on the other side of the material channel, and the clamping plate A ferrule outer corner clip 4 is arranged inside the fixed connection seat 3, both ends of the ferrule outer corner clip 4 run through the clip fixed connection seat 3, and extend to one side of the outer wall of the clip fixed connection seat 3 and into the material channel;

[0028] The top of one end of the feedway is provided with a measuring head up and down mov...

Embodiment 2

[0032] The difference with embodiment 1 is:

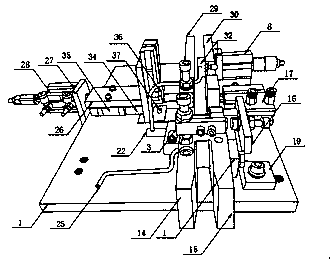

[0033]The two sides of the feedway are respectively provided with a short material left clamp 14 and a short material right clamp 15, and the short material left clamp 14 and short material right clamp 15 are fixedly arranged on the bottom plate 1, and the short material right The bottom of one end of the clamping plate 15 is provided with a third cylinder fixing seat 16, and one side of the bottom end of the third cylinder fixing seat 16 is fixedly provided with a retaining ring cylinder 17, and the output end of the retaining ring cylinder 17 is provided with a retaining ring nylon head 18, The bottom end of the retaining ring nylon head 18 runs through the third cylinder fixing seat 16, and extends to one side of the bottom end of the third cylinder fixing seat 16, and one side of the third cylinder fixing seat 16 is fixedly provided with a rail fixing connector 19 , the rail fixing connector 19 is arranged at the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com