Fast lifting nut

A lifting nut, fast technology, applied in the direction of lifting devices, etc., can solve the problems of slow working speed, low efficiency, and inability to achieve rapid lifting, etc., to save the operator's time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

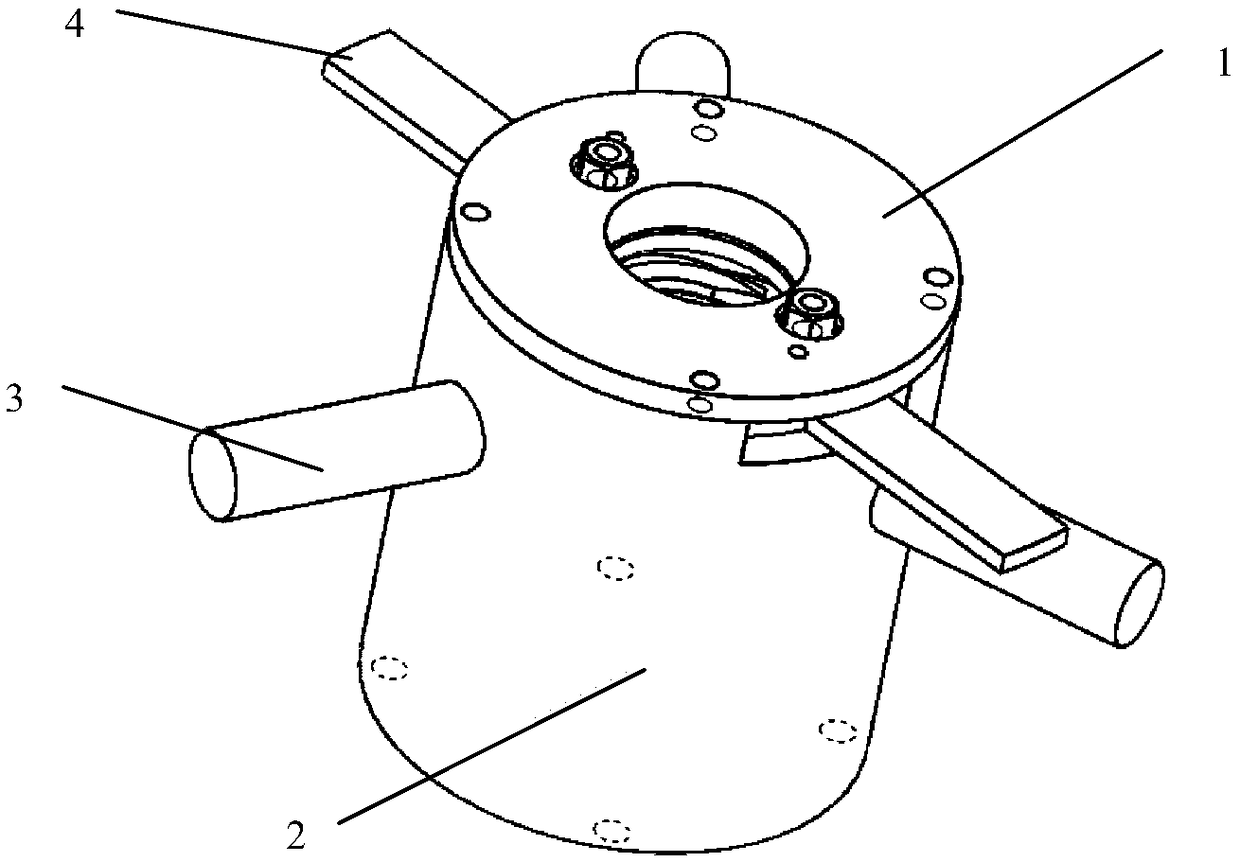

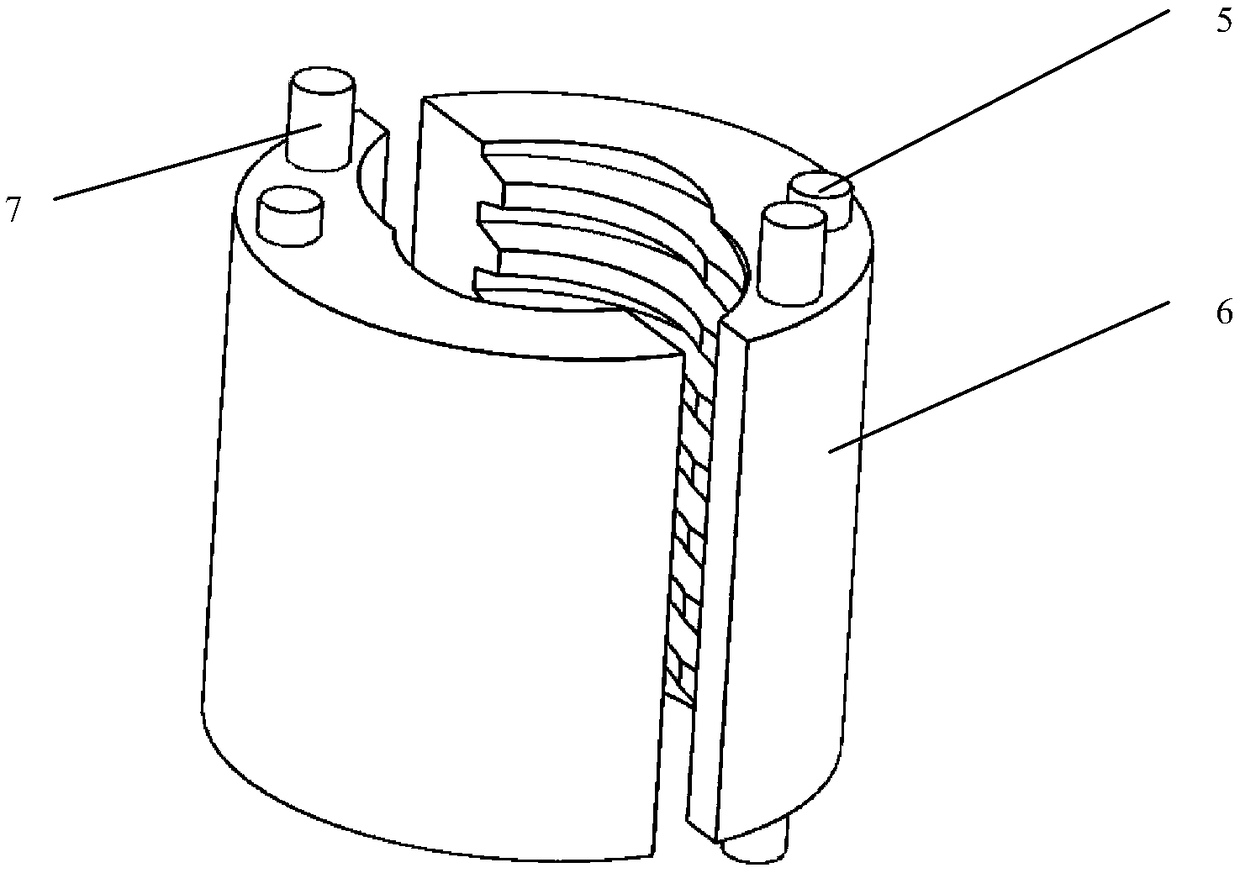

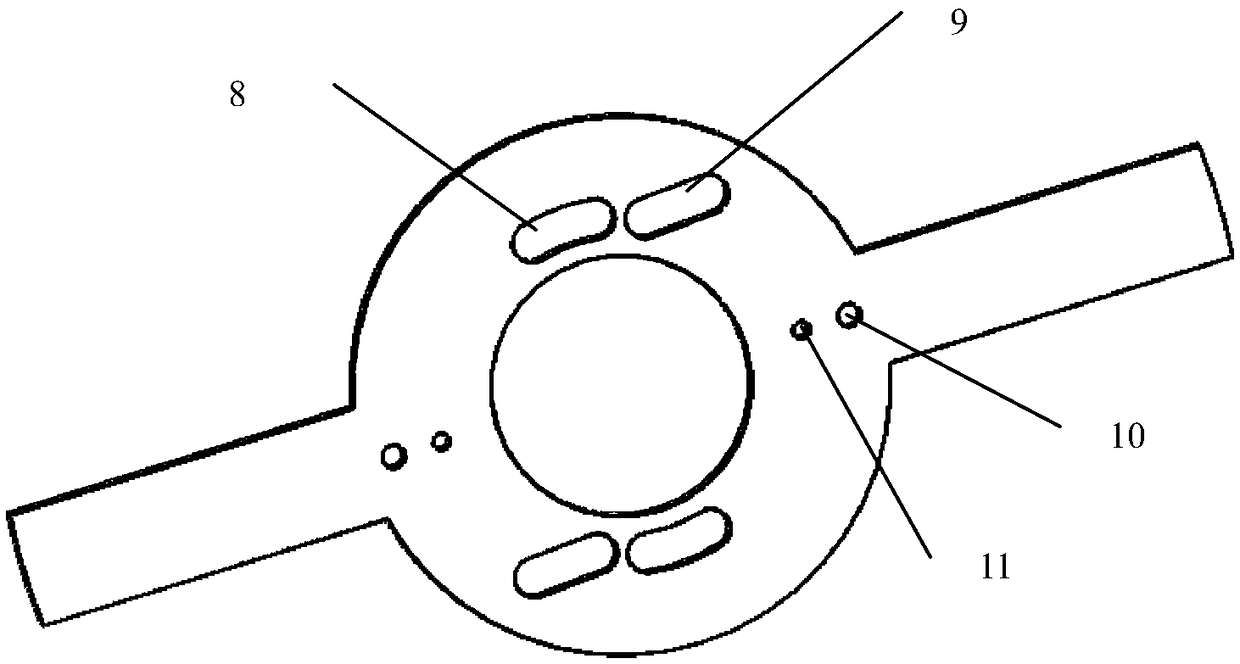

[0022] Such as figure 1 As shown, a quick-lifting nut of the present invention comprises a housing 2, a handle 3, a moving pin 5, a nut 6 and a fixed pin 7, wherein the nut 6 is a split structure of two halves of a cylindrical split nut, and on the nut 6 There are fixed pins 7 and moving pins 5, and the two nuts 6 are installed on the inner round platform of the casing 2 through their respective fixing pins 7, and the two nuts 6 are connected with the turntable 4 located at the end of the casing 2 through the moving pins 5. The end cover 1 is installed on the top of the turntable 4; the handle 3 is arranged on the outside of the shell 2.

[0023] Half of the thread in each nut 6 is cut clockwise, and the remaining part forms two sections of concentric arcs after the two nuts 6 are fastened together. The thread longitudinal section in the nut 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com