Control method of water pump

A control method and technology of water suction pumps, which are applied to the control devices of washing machines, textiles and papermaking, household appliances, etc., can solve the problems of low tap water pressure, no tap water, and discontinuous supply, so as to prolong the service life, avoid time detection, The effect of reducing the frequency of startup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

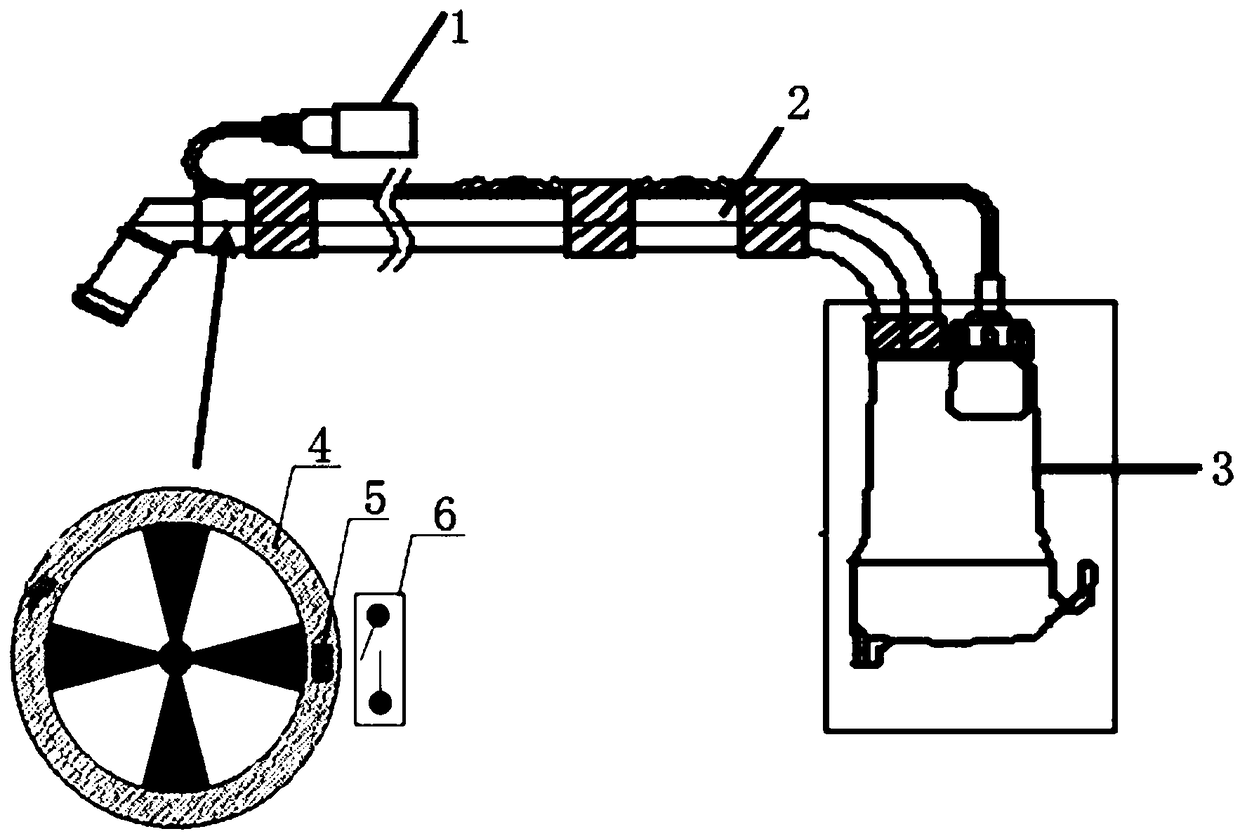

Image

Examples

Embodiment 1

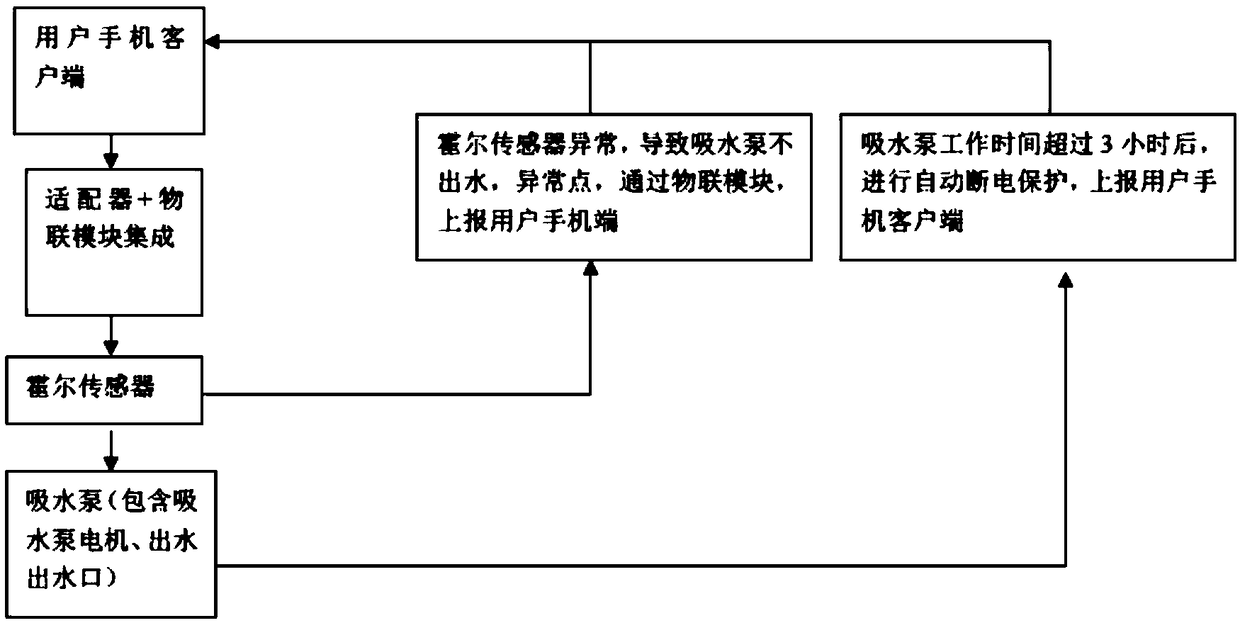

[0030] Such as figure 2 As shown, this embodiment introduces a control method of a water suction pump. The water suction pump is started and started to work. After detecting that the water outlet pipe of the water suction pump is out of water, start timing t1, and when the timing time t1 reaches the set time T1, determine The pump motor of the water suction pump works overtime, and the water suction pump is controlled to stop working.

[0031] In the present invention, by controlling the pump motor to stop working after the work exceeds a certain value, the damage caused by the overtime work of the pump motor is avoided, and the service life of the pump motor is prolonged. However, the present invention places the detection of the working time of the pump motor in the outlet pipeline of the water suction pump After the water comes out, instead of after the pump motor works, the reason is that the pump motor works during the working process of the pump motor of the present inv...

Embodiment 2

[0041] The difference between this embodiment and Embodiment 1 is that after t1 reaches T1 and the pump motor stops working, start counting, and judge whether the counted time t2 reaches the time required for the temperature to drop from the temperature when the pump motor stops working to the temperature when it can work again T2, if yes, start the pump motor, if not, do not start the pump motor until t2 reaches T2.

[0042] The above setting enables the stopped pump motor to start up and start working without user operation after meeting the condition of being able to work again, which simplifies the control of the water suction pump.

[0043] Accordingly, the working steps of the suction pump include:

[0044] Step 1. Start the suction pump and start working, and then perform step 2;

[0045] Step 2. Determine whether the water outlet pipe of the suction pump is out of water. If yes, start timing and execute step 3. If not, execute step 4;

[0046] Step 3, judging whether t...

Embodiment 3

[0054] The difference between this embodiment and Embodiments 1 and 2 is that before starting the pump motor, it is first judged whether the user triggers the pump motor start command, if yes, the pump motor is started, and if not, the pump motor is not started.

[0055] The above setting makes the pump motor start and work only under the operation of the user, which improves the reliability of the control of the water suction pump.

[0056] Accordingly, the working steps of the suction pump include:

[0057] Step 1. Start the suction pump and start working, and then perform step 2;

[0058] Step 2. Determine whether the water outlet pipe of the suction pump is out of water. If yes, start timing and execute step 3. If not, execute step 4;

[0059] Step 3, judging whether the counted time t1 reaches the set time T1, if yes, then execute step 5, if not, then execute step 6;

[0060] Step 4, make the pump motor stop working;

[0061] Step 5. Make the pump motor stop working, s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap