Roller washing machine vibration radiation noise prediction method based on dynamic simulation

A technology of dynamic simulation and drum washing machine, applied in the field of simulation calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

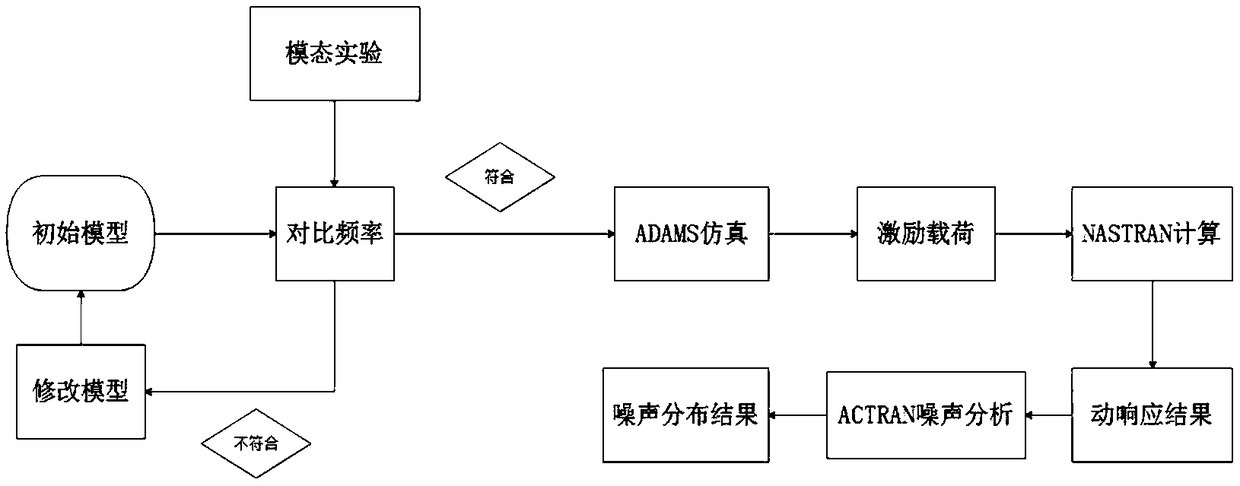

[0035] Such as Figure 2 to Figure 6 As shown, the specific implementation process of the vibration radiation noise prediction method of drum washing machine based on dynamic simulation in the present invention is:

[0036] Step 1: Establish an accurate and credible box model according to the actual mode of the box, such as figure 2 shown;

[0037]Step 2: Assemble the box body and the remaining rigid body model in the virtual prototyping software Adams, give the inner drum an initial rotation speed, and obtain the excitation of the flexible connection point.

[0038] The third step: Import the box model into Patran, import the excitation obtained in the second step at the flexible connection point, and obtain the vibration response result of the box through patran frequency response analysis.

[0039] The fourth step: Import the established acoustic model and the vibration response results obtained in the third part into Actran to calculate the vibration radiation noise of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com