car luggage rack

A car luggage rack and car technology, applied in the field of auto parts, can solve the problems of poor shock absorption and buffering effect of the luggage rack, and the inability to adjust the spacing of the supporting beams, etc., to achieve the effect of reducing the fluctuation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

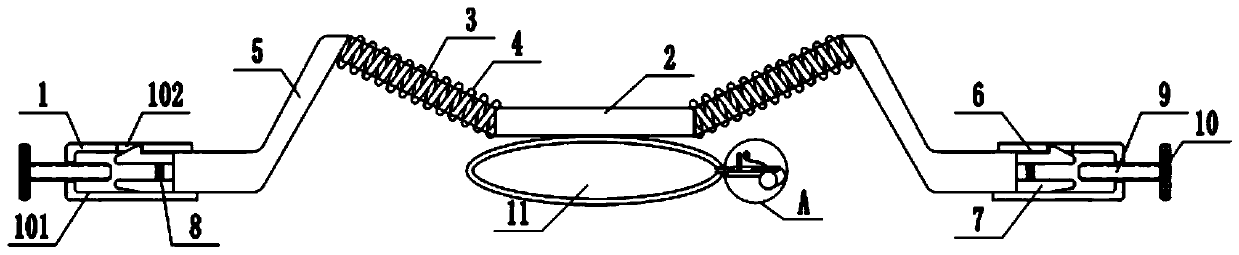

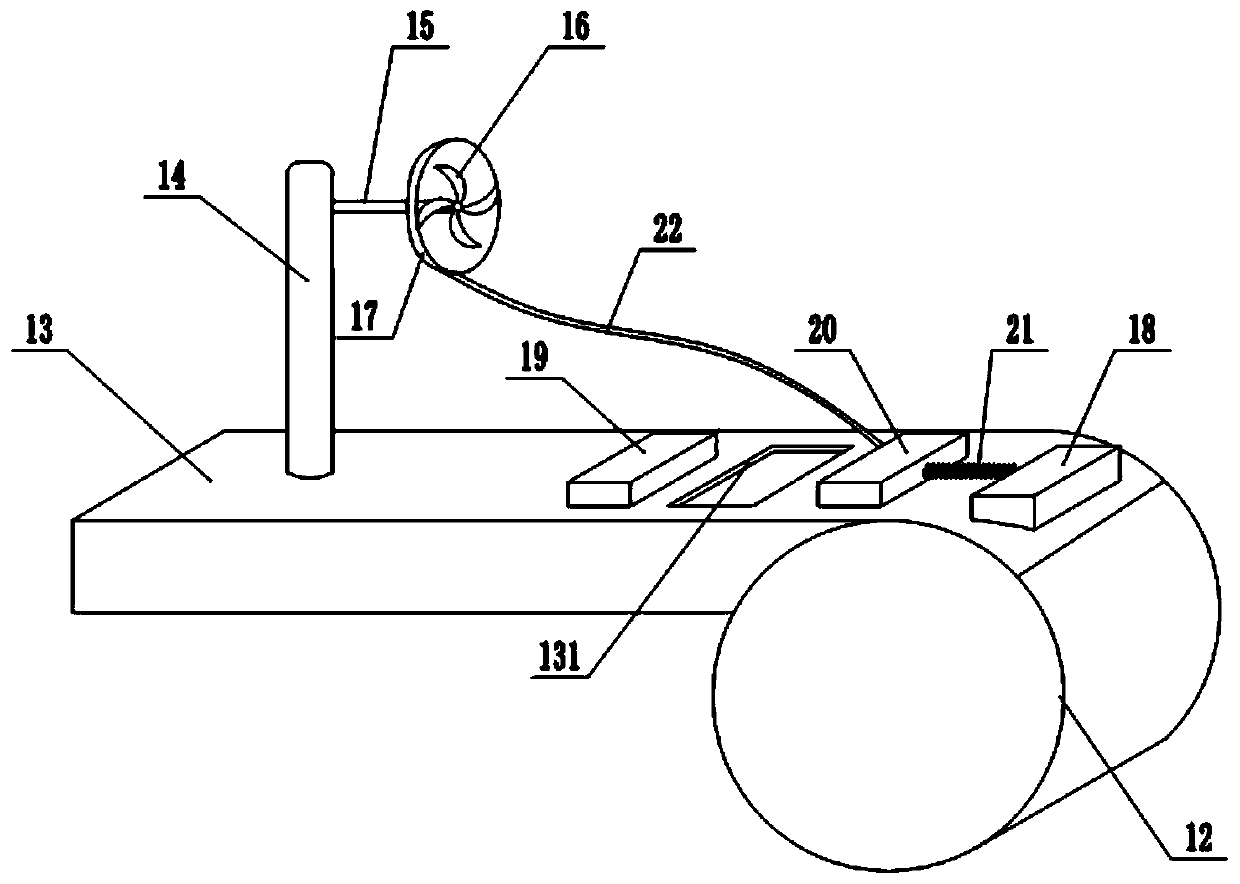

[0017] The reference signs in the accompanying drawings of the specification include: mounting seat 1, first groove 101, snap opening 102, storage board 2, telescopic rod 3, first tension spring 4, support rod 5, first snap plate 6, second Clamping plate 7, spring 8, threaded rod 9, handle 10, elastic air bag 11, whistle body 12, mouthpiece 13, air release port 131, support column 14, rotating shaft 15, rotating blade 16, ring body 17, first stopper 18. The second block 19 , the slide plate 20 , the second tension spring 21 , and the second flexible pull cord 22 .

[0018] The embodiment is basically as attached figure 1 , attached figure 2 Shown: a car luggage rack, including two elongated mounting bases 1, the mounting bases 1 are fixed on the top of the car, the side wall of the mounting base 1 is provided with a first groove 101, and the first groove 101 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com