Manufacturing method of one-sided protective polarizing film with adhesive layer

A technology of an adhesive layer and a manufacturing method, which can be applied to film/sheet-like adhesives, adhesives, polarizers, etc., and can solve problems such as insufficient thermal shock durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0231]

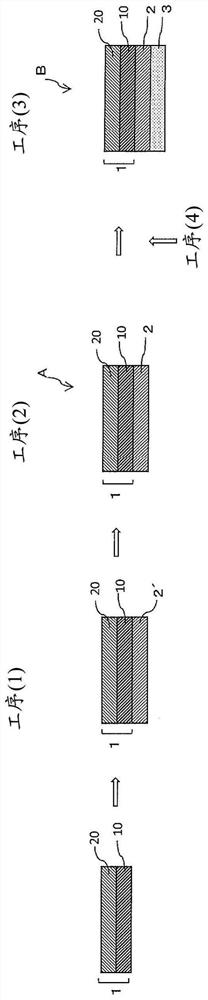

[0232] Using a coating device (specifically, a gravure coater), on the surface of the polarizer of the above-mentioned one-side protective polarizing film (the surface of the polarizer without a protective film) conveyed at 20 m / min, the thickness after drying is 1 μm. The material for forming the transparent resin layer (coating liquid) was applied in the same way, and then dried with hot air at 85° C. for 30 seconds to prepare a one-side protective polarizing film with a transparent resin layer.

[0233]

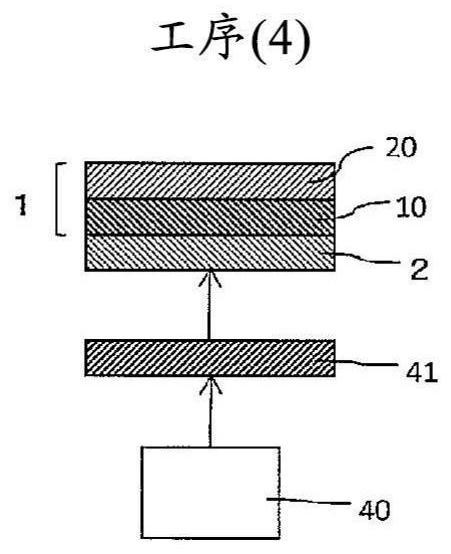

[0234] Next, without winding the above-obtained one-side protective polarizing film with a transparent resin layer into a roll, the above-mentioned transparent resin layer was continuously bonded (specifically, after 18 seconds) and formed on the above-mentioned release sheet (separator). The pressure-sensitive adhesive layer on the peeling-treated surface was prepared to produce a pressure-sensitive adhesive layer-attached polarizing film. Then, the polarizin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com