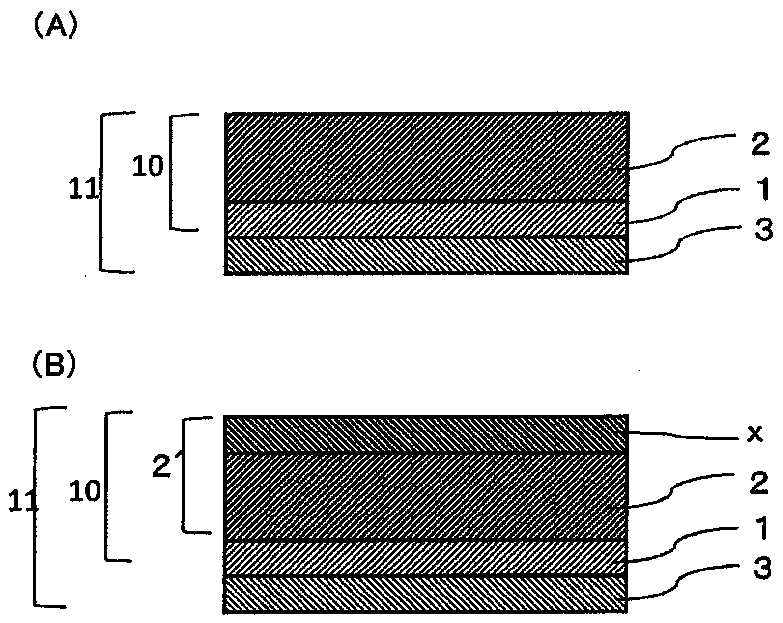

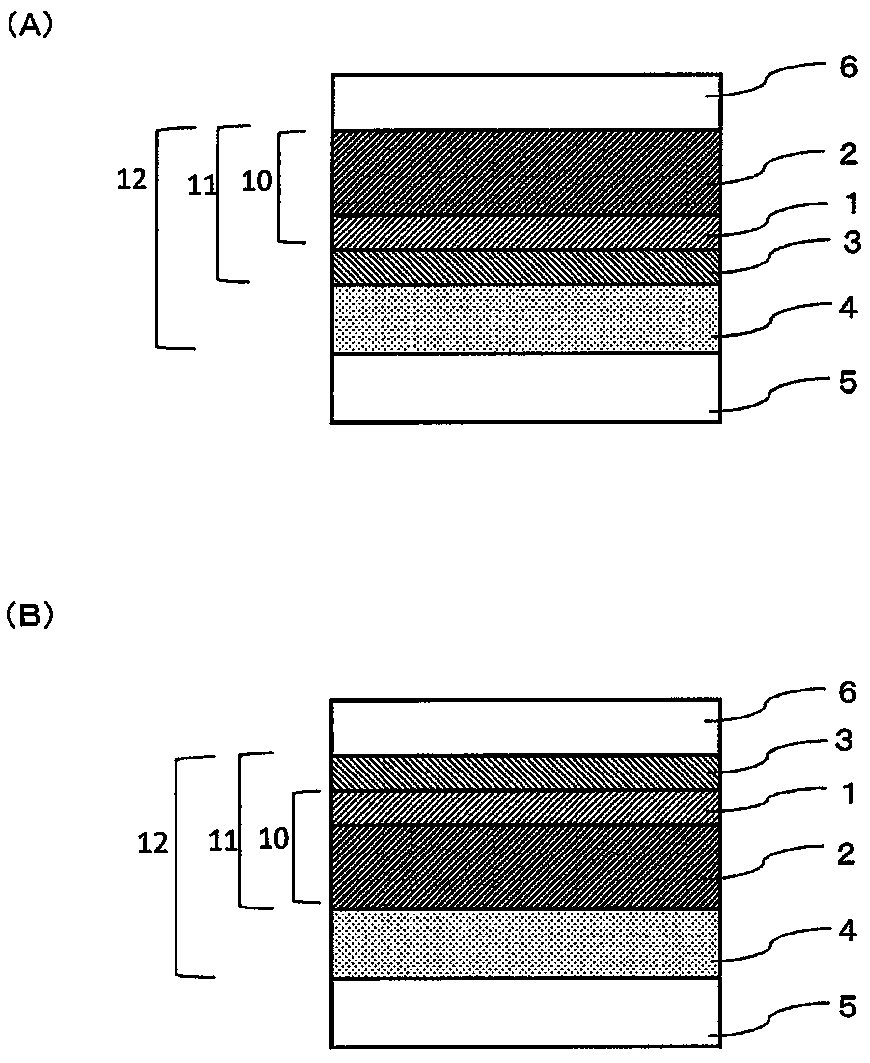

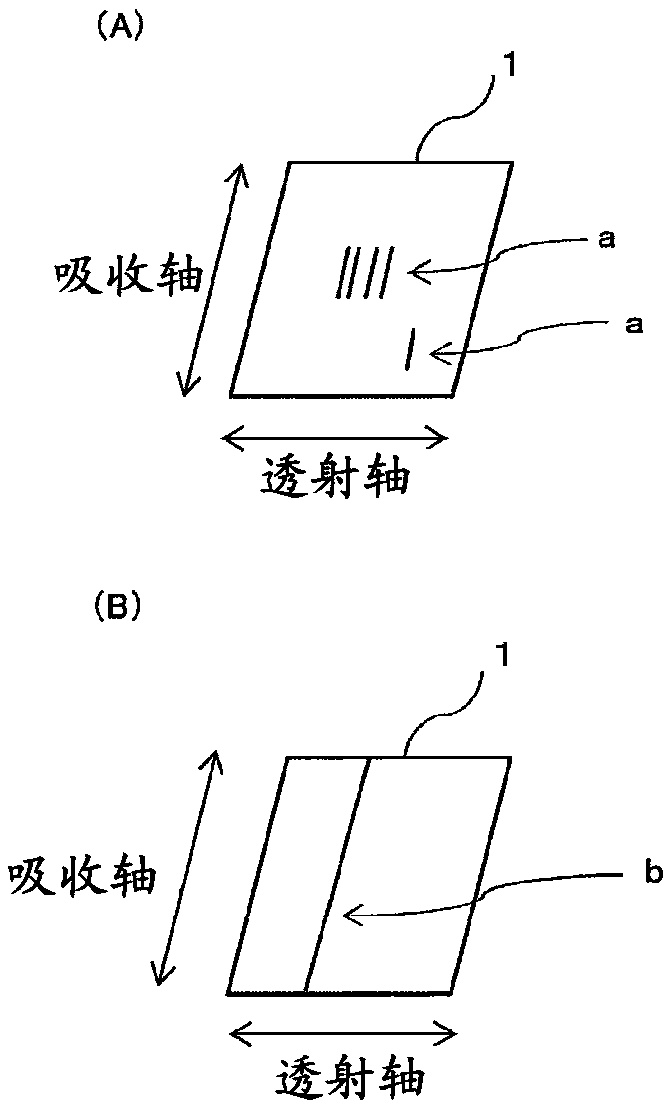

One-side protected polarizing film, polarizing film with adhesive layer, image display device, and method for continuously manufacturing image display device

A technology of adhesive layer and polarizing film, applied in the direction of identification device, polarizing element, lighting device, etc., can solve the problems of insufficient durability, easy generation, cracks, etc., achieve small changes in shrinkage stress, and suppress the generation of through cracks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0170] (Manufacturing of one-sided protective polarizing film A1)

[0171] On the surface of the polarizer A1 of the above-mentioned optical film laminate, the above-mentioned ultraviolet curable adhesive is applied so that the thickness of the adhesive layer after curing is 0.5 μm, and the above-mentioned protective film is attached, and then irradiated as active energy rays. UV light to cure the adhesive. Gallium-encapsulated metal halide lamp was used for ultraviolet irradiation, irradiation device: Light HAMMER10 manufactured by Fusion UV Systems, Inc., valve: V valve, maximum illuminance: 1600mW / cm 2 , cumulative exposure 1000 / mJ / cm 2 (Wavelength: 380-440 nm), and the illuminance of an ultraviolet-ray was measured using the Sola-Check system by Solatell company. Next, the amorphous PET base material was peeled off, and the one-sided protective polarizing film A1 using a thin polarizer was produced.

[0172](Manufacture of single-side protective polarizing film with tra...

Embodiment 2~7、 comparative example 1~3

[0177] In Example 1, as shown in Table 1, the type (thickness) of the polarizer, the forming material of the transparent layer, and the thickness were changed. In the same manner as in Example 1, a single-side protective polarizing film with a transparent A protective polarizing film on one side of the layer, and a polarizing film with an adhesive layer. In addition, in Comparative Examples 1 and 3, no transparent layer was formed.

[0178] The following evaluation was performed about the polarizing film with an adhesive layer obtained in the said Example and the comparative example. The results are shown in Table 1. Unless otherwise specified, the following evaluations were performed under the conditions of 23° C. and 65% RH.

[0179]

[0180] The single-body transmittance T and the degree of polarization P of the obtained one-side protective polarizing film were measured using a spectral transmittance meter (Dot-3c of Murakami Color Technology Laboratory) with an integra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile modulus | aaaaa | aaaaa |

| luminance | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com