Method for producing polarizing film protected on one side and equipped with adhesive layer

A technology of adhesive layer and manufacturing method that can solve problems such as insufficient thermal shock durability when applied to film/sheet-shaped adhesives, adhesives, polarizing elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0231]

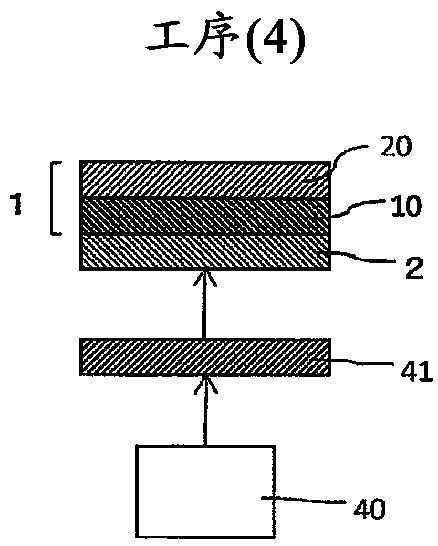

[0232] Using a coating device (specifically, a gravure coater), apply the above-mentioned one-side protective polarizing film on the polarizer surface (polarizer surface without a protective film) conveyed at 20 m / min to a thickness of 1 μm after drying. The forming material (coating liquid) of the transparent resin layer was coated by the method, and then dried with hot air at 85° C. for 30 seconds to produce a single-sided protective polarizing film with a transparent resin layer.

[0233]

[0234] Next, without winding the one-sided protective polarizing film with the transparent resin layer obtained above into a roll shape, continue (specifically, after 18 seconds) to bond and form the above-mentioned release sheet (separator) on the above-mentioned transparent resin layer. The adhesive layer on the treated surface was peeled off to prepare a polarizing film with an adhesive layer. Then, the polarizing film with an adhesive layer was wound up to make a roll. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com