One-sided protective polarizing film with adhesive layer, image display device and continuous manufacturing method thereof

一种图像显示装置、粘合剂层的技术,应用在薄膜/薄片状的粘合剂、胶粘剂、偏振元件等方向,能够解决耐久性不足、热冲击耐久性不足、裂纹等问题,达到抑制贯穿裂纹的产生、收缩应力的变化小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~24、 comparative example 1~8

[0228]

[0229] The adhesive layer with the film thickness shown in Table 3 formed on the release-treated surface of the release sheet (separator) was bonded to the single-sided protective polarizing film shown in Table 3 with the adhesive shown in Table 3. On the polarizer side, a single-side protective polarizing film with an adhesive layer was produced.

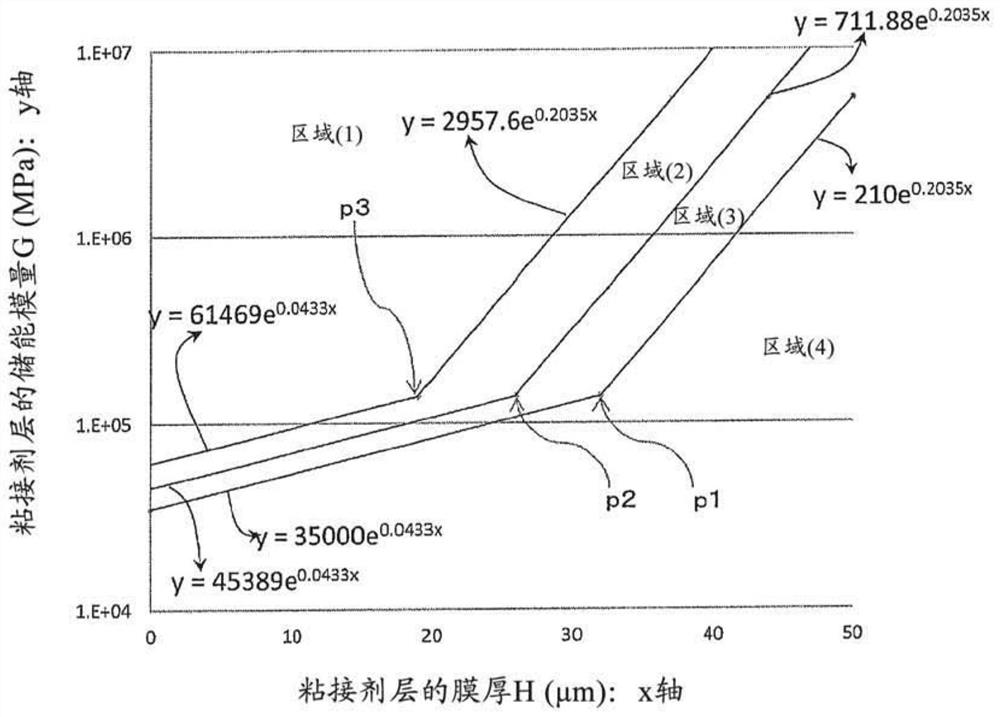

[0230] The following evaluations were performed on the one-sided protective polarizing film with an adhesive layer obtained in the above-mentioned Examples and Comparative Examples. The results are shown in Table 3. In addition, the relationship between the film thickness of the adhesive layer and the storage modulus is shown in Table 3, which belongs to figure 2 Which area of the chart for .

[0231]

[0232] The single-body transmittance T and the degree of polarization P of the obtained single-side protective polarizing film were measured using a spectral transmittance meter (Dot-3c of Murakami Color Technology...

Embodiment 25

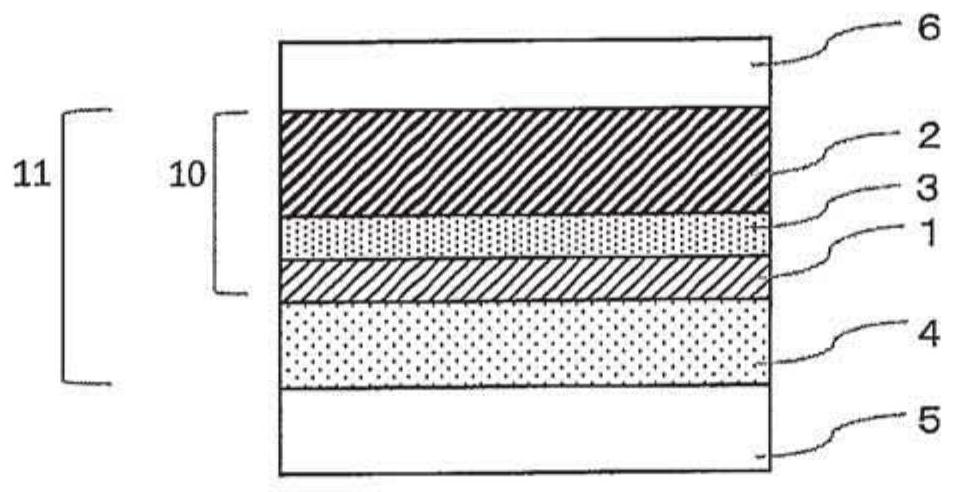

[0263] A long film was used as a single-sided protective polarizing film, a forming material was applied with a micro-gravure coater, and a long film was used as the above-mentioned release sheet (separator) and the following surface protection film , except that, the same operation as in Example 10. Thus, a one-sided protective polarizing film with an adhesive layer in which a separator was laminated on the polarizer side of the one-sided protective polarizing film and a surface protective film was laminated on the transparent protective film side ( figure 1 way) winding body. It should be noted that, through the slit processing of cutting based on the continuous conveyance of the one-side protective polarizing film with the adhesive layer, the width corresponds to the short side and the long side of the 32-inch non-alkali glass, respectively, and the adhesive tape is prepared. One side of the mixture layer protects the winding body group of the polarizing film.

[0264] (S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile modulus | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com