Assembly for suspension of vehicle comprising pivot ball joint screwed into suspension triangle

A suspension device, triangular piece technology, applied in vehicle parts, transportation and packaging, cantilevers mounted on pivots, etc., can solve problems such as unfavorable production costs, complex production of specific shapes, and incompatible assembly methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

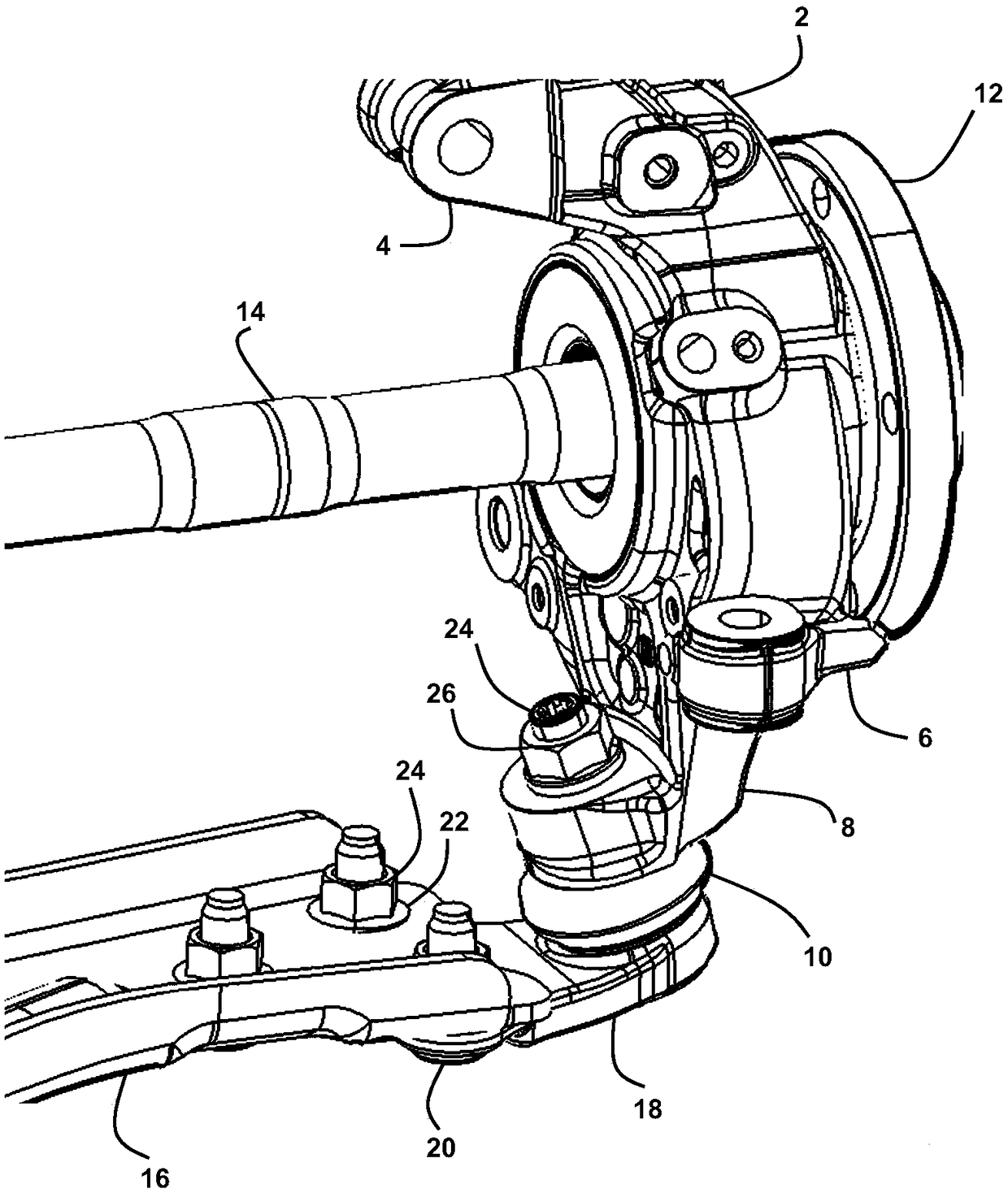

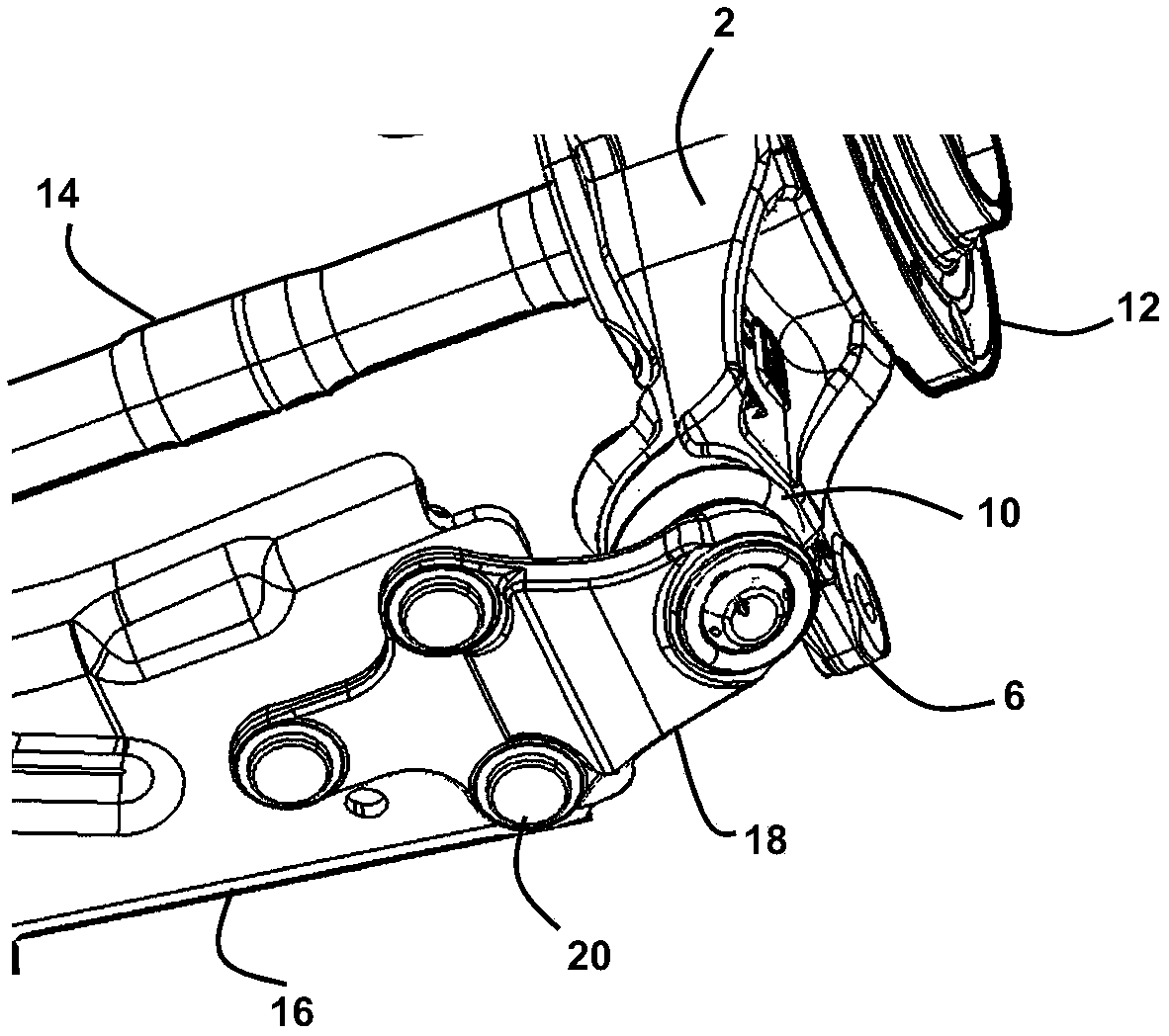

[0031] Figures 1 and 2 show a hub carrier 2, the upper part of which comprises fastening means 4 which receive the base of the buffer, and which comprises a rearwardly facing steering arm 6 which The ball joint that receives the steering linkage.

[0032] The base of the hub carrier 2 comprises a lower arm 8 with a substantially vertical hole receiving a rod 24 of a pivoting ball joint 10 arranged below, which is fastened by a nut 26 from above .

[0033] The hub carrier 2 supports by means of bearings a hub 12 for receiving a vehicle wheel, said hub being driven by a transmission shaft 14 passing through said hub.

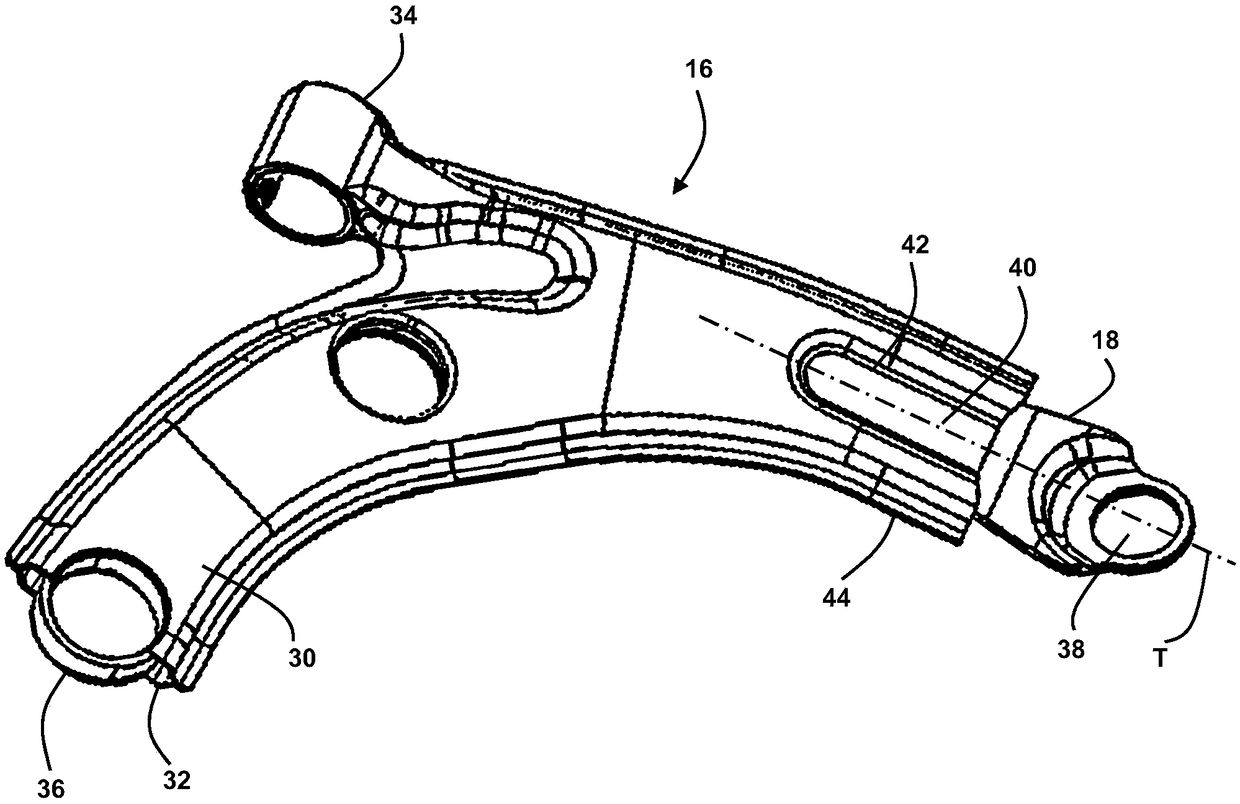

[0034] A lower suspension triangle 16 is coupled from the inside to the front frame of the vehicle by hinge means and its outer end receives a substantially planar plate 18 which is fixed below the triangle. The plate 18 has an outwardly upwardly concave shape which forms the housing of the pivoting ball joint 10 .

[0035] The fixing means of the plate 18 cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com