Sand and gravel material dust cover and its installation method and use method

An installation method and dust cover technology are applied in the field of sand and gravel material stacking devices, which can solve the problems of material waste, difficulty in control, muddy construction site, etc., and achieve the effect of reasonable application and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

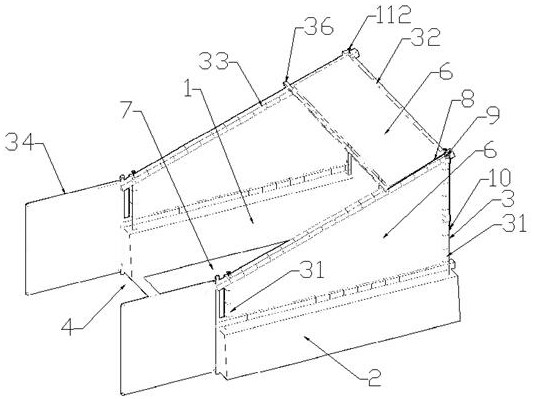

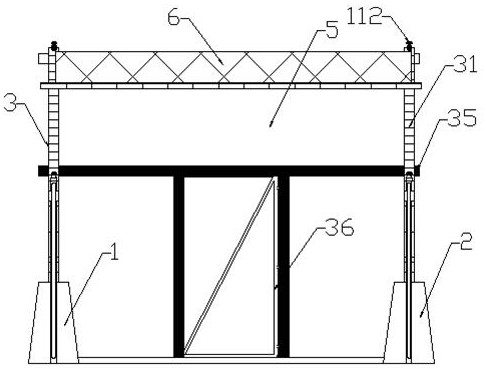

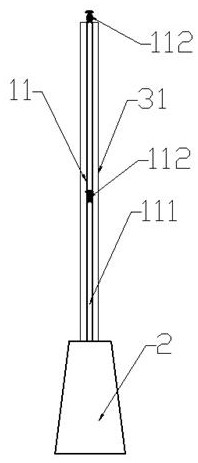

[0028] As shown in the figure, the gravel material dust cover provided in this embodiment includes a left mud retaining wall 1, a right mud retaining wall 2 and a dustproof cloth fixedly installed on the left mud retaining wall 1 and the right mud retaining wall 2 Install the frame 3, the dust-proof cloth installation frame 3 and the left mud retaining wall 1 and the right mud retaining wall 2 form a dust-proof frame, and the front and rear sides of the dust-proof frame form a stocking port 4 and a discharge port 5 respectively, preventing The internal space surrounded by the dust frame is the sand and gravel material stacking space 7; the front and rear sides, left and right sides and the top surface of the dust frame are all sealed by dust cloth 6, wherein the dust cloth on the front and rear sides and The dustproof cloth on the top surface can be folded or opened and closed. In this embodiment, the left mud retaining wall 1 and the right mud retaining wall 2 are arranged at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com