Flame-retardant cable

A technology of flame-retardant cables and flame-retardant layers, which is applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of costing money, manpower and material resources, and unfavorable continuous operation of cables, so as to improve safety, stability, and flame-retardant effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

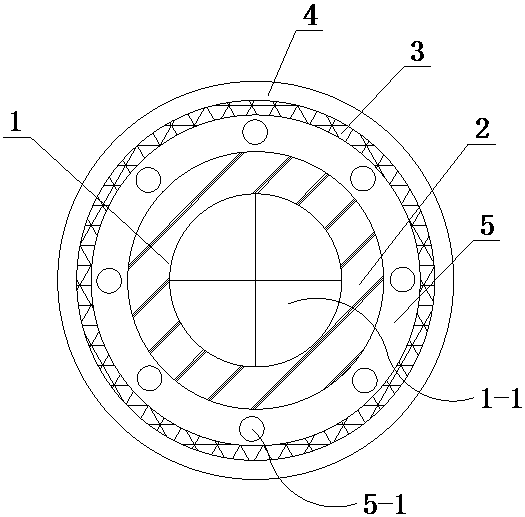

[0016] Such as figure 1 A flame retardant cable shown includes a conductor 1, an insulating layer 2, a flame retardant layer 3 and an outer sheath 4, the conductor is wrapped with an outer sheath, and an insulating layer 2 is arranged between the conductor 1 and the outer sheath 4 and a flame-retardant layer 3, a filling layer 5 is arranged between the insulating layer 2 and the flame-retardant layer 3, the conductor 1 is composed of four aluminum cores 1-1, and the cross-section of the aluminum core 1-1 is fan-shaped and combined to form a complete circle shaped conductor 1;

[0017] A plurality of temperature sensors 5-1 are arranged in the fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap