Accurate grinding tool for cylindrical part

A fine grinding and tooling technology, applied in the direction of grinding/polishing safety devices, grinding machines, manufacturing tools, etc., can solve the problem that the roundness and smoothness of the sealing surface cannot be guaranteed, the roundness and smoothness of the outer surface cannot be guaranteed, and the overall pressure level is reduced. problem, to achieve the effect of light weight, compact structure and uniform circumferential load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

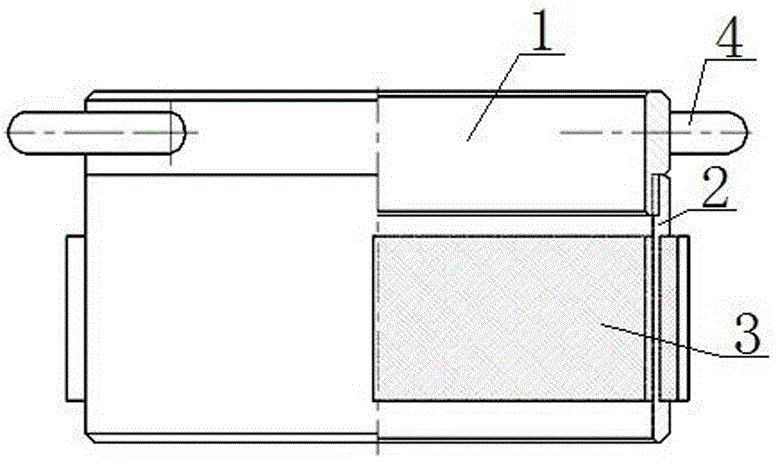

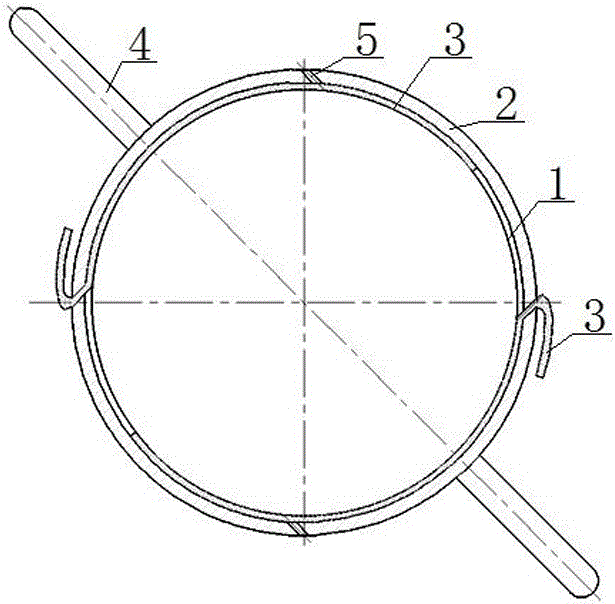

[0022] see figure 1 with figure 2 As shown, the present invention is a fine grinding tool for the fine grinding treatment of the outer surface of a cylindrical part, the cylindrical part is a casing hanger, and the outer surface is the sealing surface at the neck of the casing hanger.

[0023] The fine grinding tool includes a sizing ring 1, a friction cylinder 2 and a friction part.

[0024] Wherein, the inner diameter of the sizing ring 1 is consistent with the outer diameter of the sealing surface of the casing hanger. The outer edge of the lower portion of the sizing ring 1 is provided with a T-shaped male thread connected to the friction cylinder 2 , so as to transmit torque to the friction cylinder 2 . The outer circumference of the sizing ring 1 is provided with a hand-held portion, which is a handle 4 radially protruding and arranged on the outer circumference of the sizing ring 1. There are two handles 4, which are symmetrically arranged on the outer circumference ...

Embodiment 2

[0028] The other content of this embodiment is the same as that of Embodiment 1, except that the friction part is sandpaper.

Embodiment 3

[0030] The invention relates to fine grinding tooling for the fine grinding treatment of the outer surface of a cylindrical part, the cylindrical part is a casing hanger, and the outer surface is a sealing surface at the neck of the casing hanger.

[0031] The fine grinding tooling includes a sizing ring, a friction cylinder and a friction part.

[0032] Wherein, the inner diameter of the sizing ring is consistent with the outer diameter of the sealing surface of the casing hanger. The outer edge of the lower part of the sizing ring is provided with a T-shaped male thread connected to the friction cylinder, so as to transmit torque to the friction cylinder. The outer circumference of the sizing ring is provided with a hand-held part, which is a handle radially protruding and arranged on the outer circumference of the sizing ring. There are two handles, which are symmetrically arranged on the outer circumference of the sizing ring. Apply rotational torque.

[0033] The inner ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap