Efficient rounding and passivating device for stainless steel cut wire shot

A technology of stainless steel wire and shot cutting, which is applied to used abrasive treatment devices, explosion generating devices, abrasives, etc., can solve the problems of the effect of surface cleaning, reduce the surface finish and roughness of the workpiece, damage the surface of the workpiece, etc. High work efficiency, eliminate pollution and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

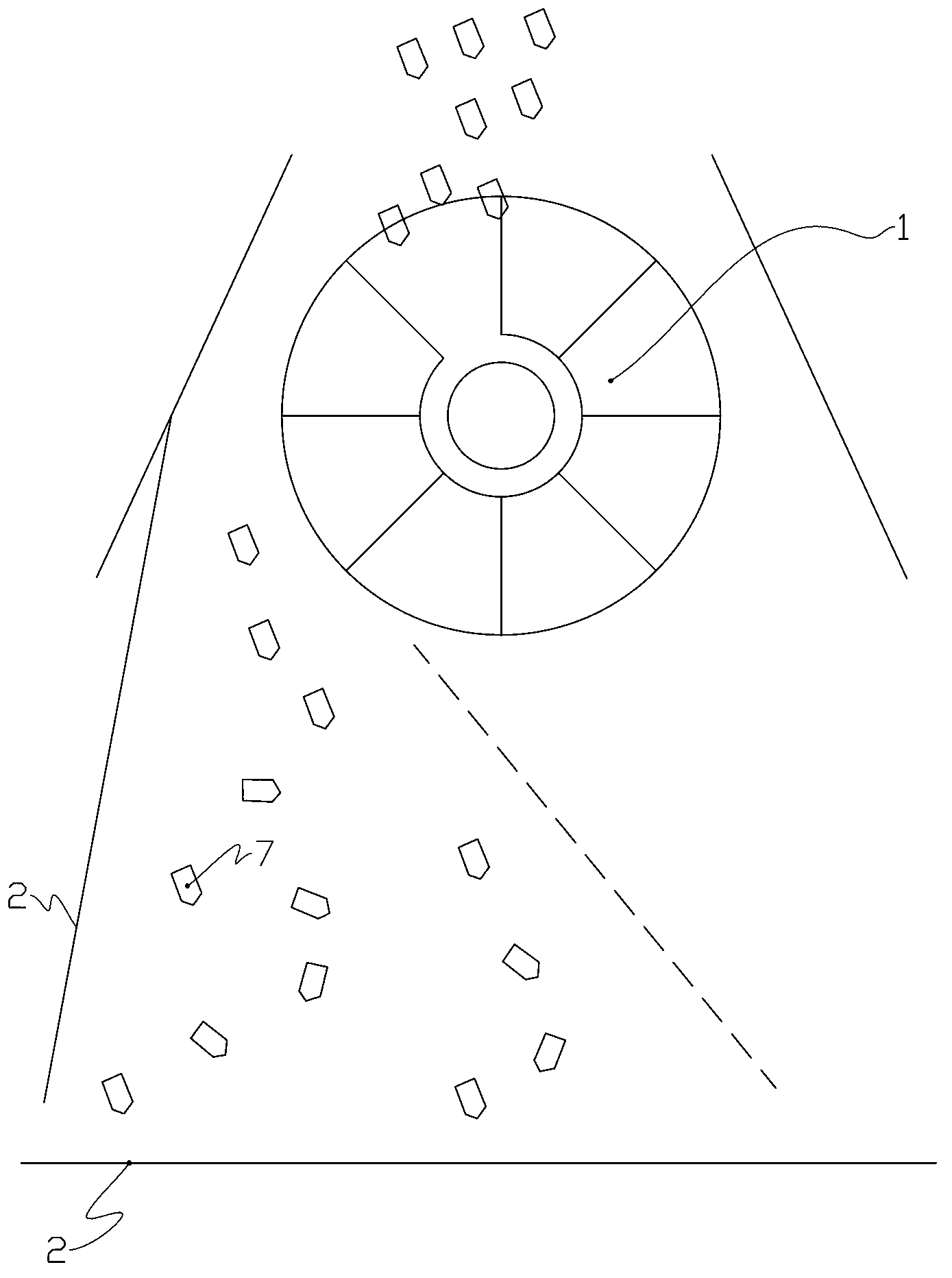

[0014] Such as Figure 1 to Figure 3 as shown,

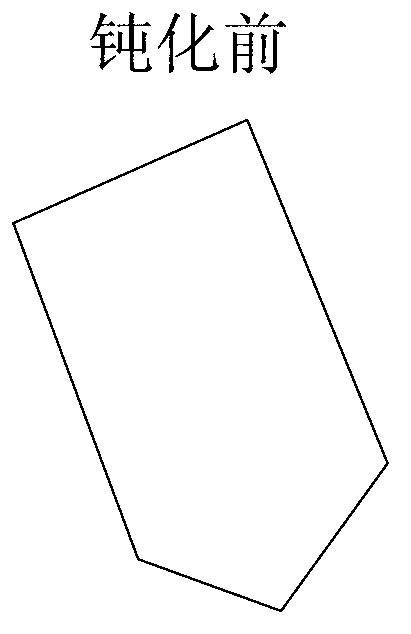

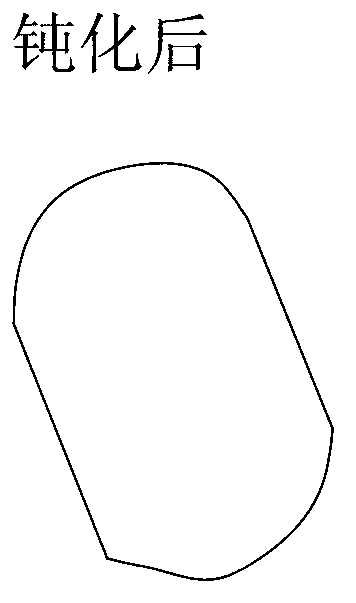

[0015] A high-efficiency stainless steel wire-cut shot grinding round passivation device includes a throwing impeller 1, a wear-resistant guard plate 2, a hoist 3, a blanking pipe 4, a material box 5, a dust collector 6 and other components. The material box 5 is a closed box, and the stainless steel cut shot at the bottom of the material box is lifted to a high place by the hoist 5, and then falls into the material box from the blanking pipe 4, and the throwing impeller 1 is installed at the entrance of the material box, and the throwing impeller is The specific shape of the spiral impeller can be designed by itself, and it only needs to be able to function as a high-speed parabola. The wear-resistant guard plate 2 is installed around the throwing impeller, and the throwing impeller works under the drive of the driving motor. Use a high-speed driving motor to drive the throwing impeller like a propeller. When the stainless ste...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap